Underground engineering multi-span multi-layer tunnel excavation method

A technology for tunnel excavation and underground engineering, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as strong limitations, high cost, and high risks, and achieve low engineering cost, short construction period, and reduce excavation risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

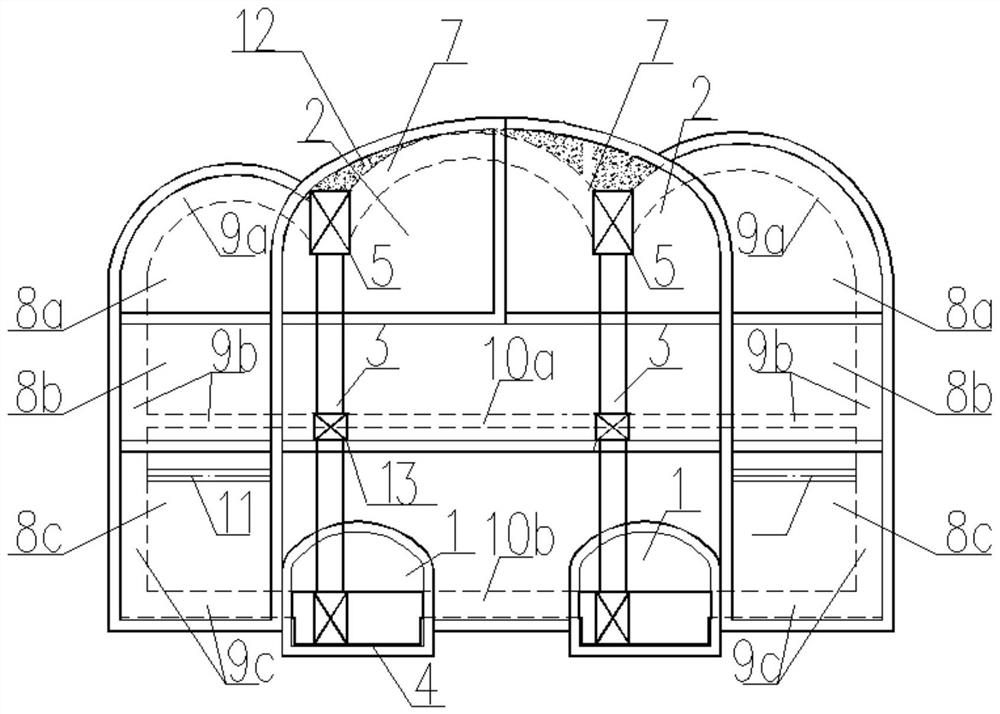

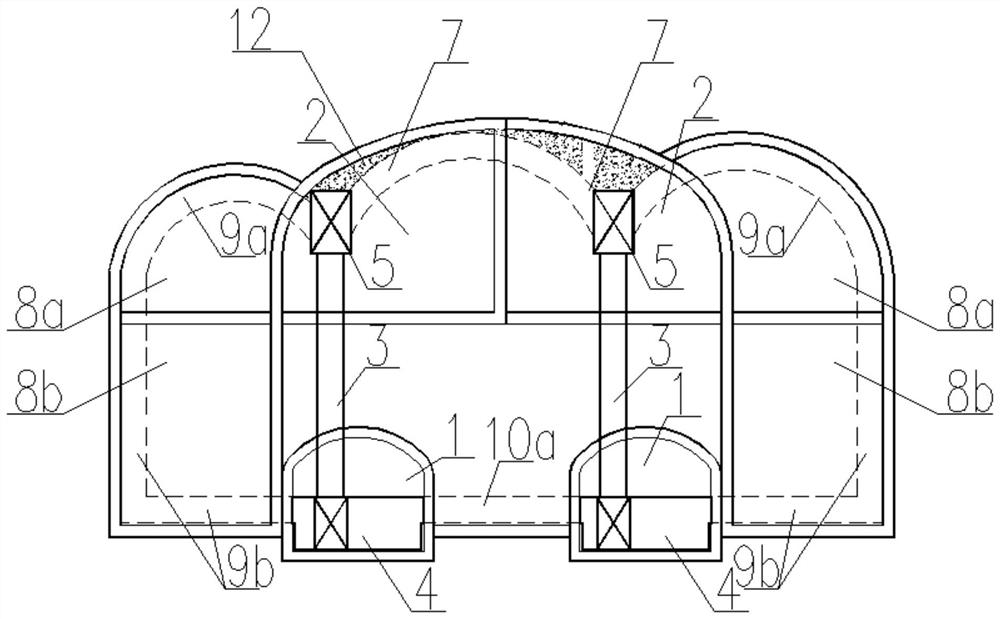

[0030] Embodiment 1: as figure 1 , 3 As shown, a method for excavating multi-span and multi-storey tunnels in underground engineering comprises the following construction steps:

[0031] S1, construct super-strong support for the bottom pilot tunnel at the connection of each span, excavate the bottom pilot tunnel 1, and construct the bottom longitudinal beam foundation structure 4 in the lower pilot tunnel 1;

[0032] S2, construction of super-strong support for the top pilot tunnel at the connection of each span, excavation of the upper pilot tunnel 2 corresponding to the lower pilot tunnel 1, and construction of the top longitudinal beam structure 5 in the upper pilot tunnel 2;

[0033] Among them, the construction sequence of the lower pilot tunnel 1 and the upper pilot tunnel 2 and the excavation distance between horizontal and vertical adjacent pilot tunnels can be determined according to the characteristics of the stratum and tunnel engineering.

[0034] S3, adopting t...

Embodiment 2

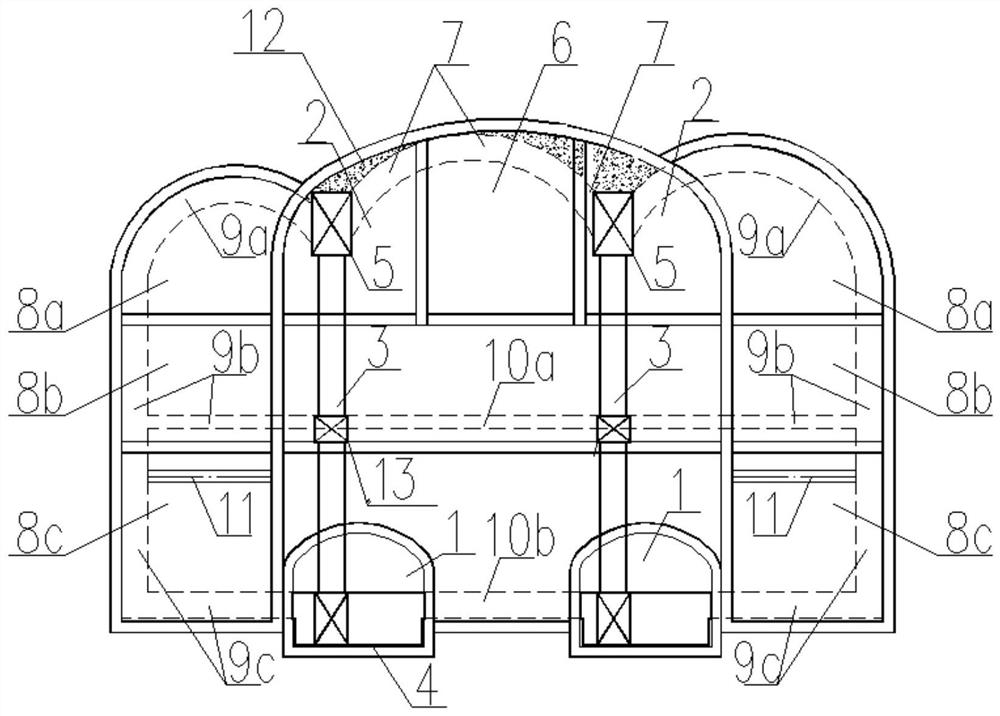

[0044] Embodiment 2: as figure 2As shown, a method for excavating multi-span and multi-storey tunnels in underground engineering differs from Embodiment 1 in that, in the step S4, excavation is used to connect two upper pilot tunnels 2 between the top structural columns 3 of each span. The middle guide hole 6, the arch structure is composed of the middle guide hole 6 and the primary branches of the arch portion of the two upper guide holes 2 combined. In step S7, it is also necessary to break the initial support structure of the pilot hole 6 between the spanning structural columns 3 .

[0045] Among them, during the construction of tunnels with more than three spans by underground excavation method, the horizontal excavation distance between the middle pilot tunnel 6 where the arch roof structure between the structural columns of each span is located can be determined according to the characteristics of the stratum and engineering characteristics; Construction advance suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com