Treatment method for phosphate hiding phenomenon of steam pocket boiler

A technology of hidden phenomena and treatment methods, which is applied in the field of treatment of phosphate hidden phenomena in drum furnaces, to achieve the effect of avoiding multiple pressures and eliminating phosphate hidden phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for processing the hidden phenomenon of phosphate in a drum furnace, comprising the following steps:

[0016] (1) According to the water quality of condensed water, there is no leakage in the condenser. Use condensate hardness (= 0) and sodium content (less than 5μg / L) to judge that there is no leakage in the condenser. The system equipment mainly refers to the condenser, which is made of stainless steel and has no fine treatment device.

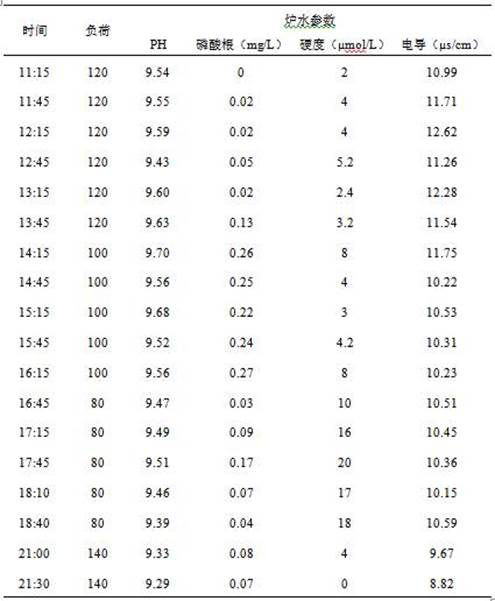

[0017] (2) Use the opportunity of reducing the load of boilers with insufficient gas to conduct experiments. According to the steam-water chemical guidelines of thermal power plants (DL / T805.2-2016): the load is reduced from 140, 120, 100, and 80 MW / h in sequence, and each load is stable Last for about 2 hours, test the pH, phosphate, hardness and conductivity of the furnace water every 30 minutes, and record the data as shown in Table 1. It can be seen from Table 1 that when the load drops from 140 to 100, the phosphate co...

Embodiment 2

[0024] A method for processing the hidden phenomenon of phosphate in a drum furnace, comprising the following steps:

[0025] (1) According to the water quality of condensed water, there is no leakage in the condenser. Use condensate hardness (= 0) and sodium content (less than 5μg / L) to judge that there is no leakage in the condenser. The system equipment mainly refers to the condenser, which is made of stainless steel and has no fine treatment device.

[0026] (2) Use the opportunity of reducing the load of boilers with insufficient gas to conduct experiments. According to the steam-water chemical guidelines of thermal power plants (DL / T805.2-2016): the load is reduced from 140, 120, 100, 80, and 50 MW / h in sequence, and each The load is stable for about 1 hour, and the pH, phosphate, hardness and conductivity of the furnace water are tested every 30 minutes, and the data are recorded in Table 2. It can be seen from Table 2 that when the load drops from 140 to 50, the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com