Ejecting evaporative cooling air-cooled heat pump module unit

An air-cooled heat pump and evaporative cooling technology, which is applied in the direction of refrigerators, compressors, mechanical equipment, etc., can solve the problems of large volume, high manufacturing cost, and high energy consumption of evaporative cooling and heat pump units, so as to reduce the volume of the unit and reduce the flying time. Water, the effect of improving the heat pump circulation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

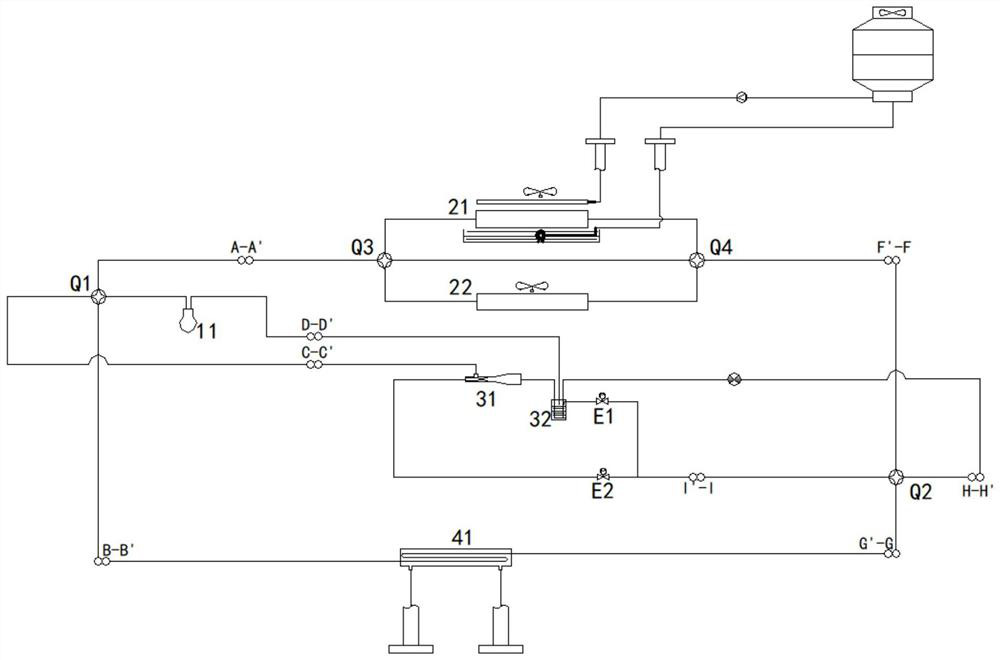

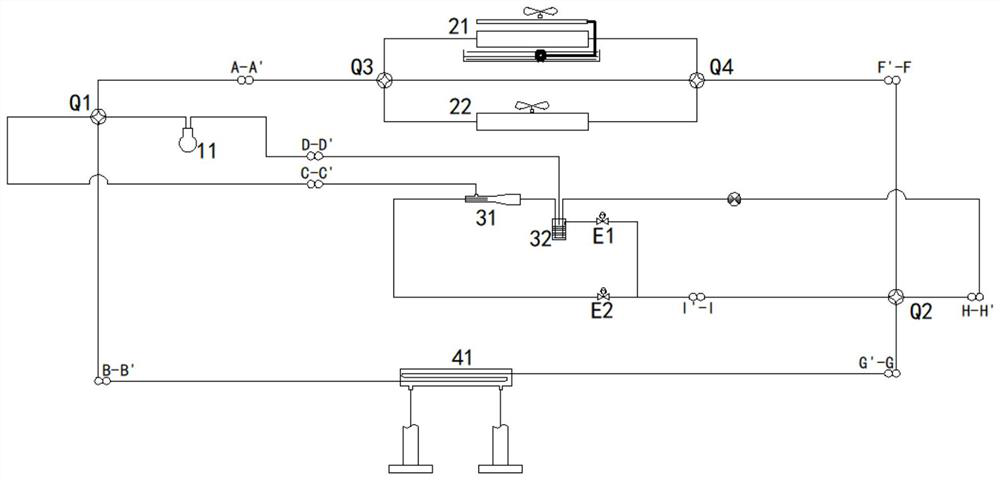

[0098] Refer Figure 17 , Air-cooled pinch refrigeration mode:

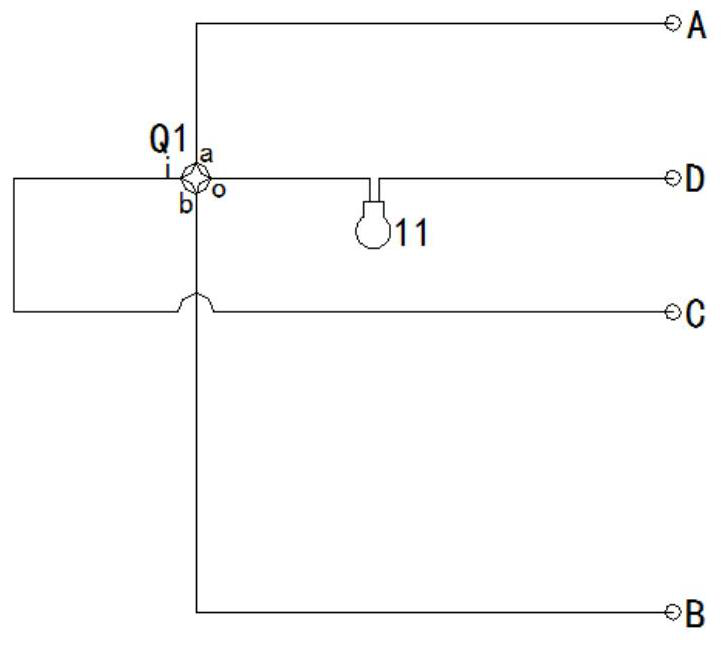

[0099] Cold Media Circulating System: The first four-pass valve Q1OA end, the Bi end is in communication; the second four-pass valve Q2OA end, the Bi end is in communication; the third four-way valve Q3IB end, the AO end is in communication; the fourth four-four-channel valve Q4OA end, the Bi end Phase; the first solenoid valve E1 is closed; the second solenoid valve E2 is turned on.

[0100] In the high pressure refrigerant circle of the refrigerant circulation, the refrigerant flows through the compressor 11 vapor port, the first valve port O and the third valve port A of the first four-pass valve Q1, the third four-way passage of the cold heat source Valve Q3 second valve port I and fourth valve port B, air source heat exchanger 22, fourth valve port B and second valve port 1 of the fourth four-channel valve Q4 I, the second four-valve Q2 of the rectifier module The first valve port O and the third valve port A, th...

Embodiment 2

[0107] Refer Figure 18 , Evaporative cold-incident refrigeration mode:

[0108] Cold Media Circulation System: The first four-way valve Q1OA end, the Bi end is connected; the second four-pass valve Q2OA end, the Bi end is connected; the third four-pass valve Q3IA end, the BO end is in communication; the fourth four-four-pass valve Q4OB end, the AI Phase; the first solenoid valve E1 is closed; the second solenoid valve E2 is turned on.

[0109] In the high pressure circuit of the refrigerant cycle, the refrigerant flows through the compressor 11 vapor port, the first four-pass valve Q1 first valve port O and the third valve port A, the cooling heat source heat exchange module Q3 second valve port I and third valve port A, evaporation cooling heat exchanger 21, the third valve port A and the second valve port I, the second valve port I, the second valve gate Q2 of the rectifier module A valve port O and a third valveperture A, the second solenoid valve E2, an emitter 31 inlet, injec...

Embodiment 3

[0116] Refer Figure 19 , Wind pre-cool evaporative introduction refrigeration mode:

[0117] Cold Media Circulating System: The first four-pass valve Q1OA end, BI end communication; second four-pass valve Q2OA end, BI end communication; third four-pass valve Q3IB end, AO end communication; fourth four four-channel valve Q4OB end, AI Phase; the first solenoid valve E1 is closed; the second solenoid valve E2 is turned on.

[0118] In the high pressure refrigerant circle of the refrigerant circulation, the refrigerant flows through the compressor 11 vapor port, the first valve port O and the third valve port A of the first four-pass valve Q1, the third four-way passage of the cold heat source Valve Q3 second valve port I and fourth valve port B, air source heat exchanger 22, fourth front valve port B, first valve port A, third four-pass valve Q3 first valve The port O and the third valve port A, the evaporation cooling heat exchanger 21, the third valve port A and the second valve po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com