Electrode cap grinding cycle energy consumption calculation system and method

A computing system and electrode cap technology, applied in the field of auto parts manufacturing, can solve problems such as complex methods, high energy consumption, poor solder joint quality, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

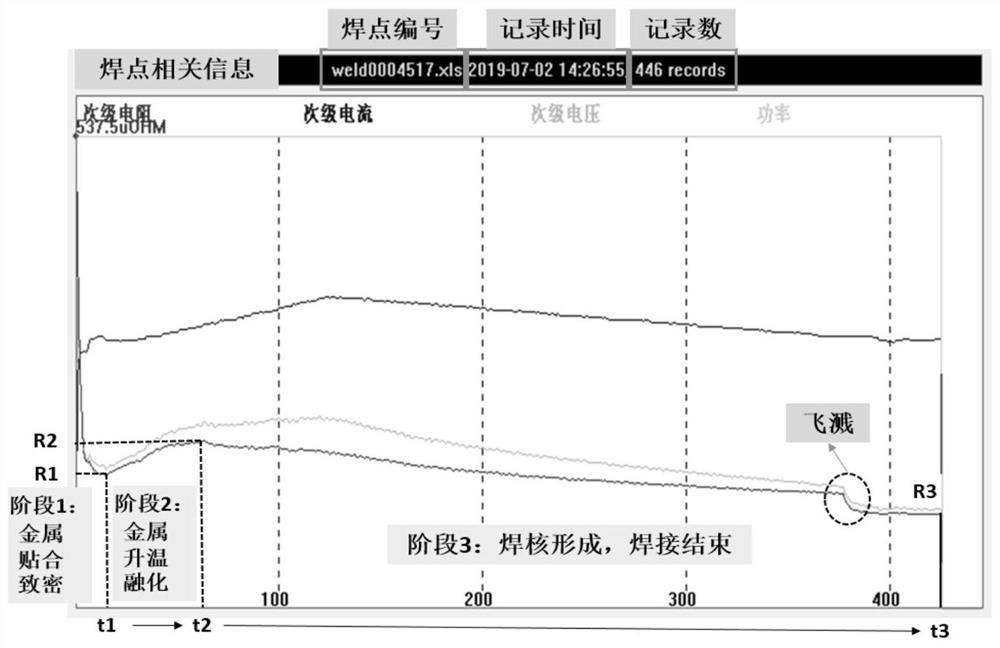

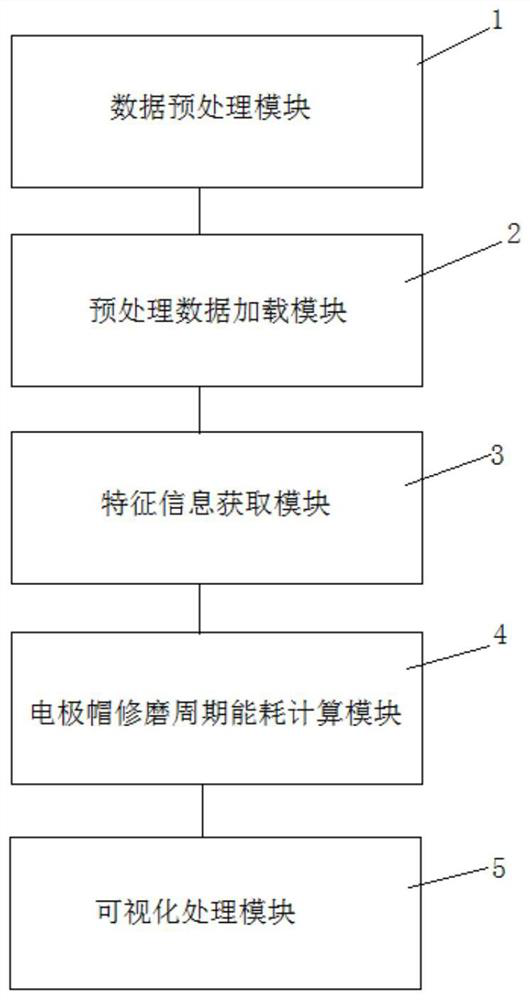

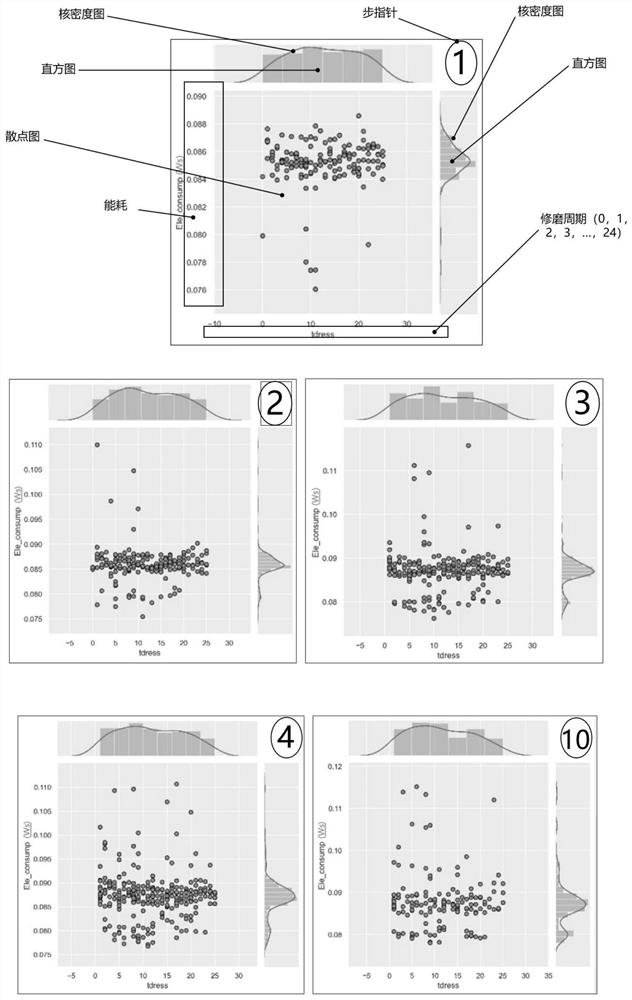

[0021] During the welding process, the electrode cap on the welding torch is a consumable, which will be consumed as the number of welding points increases, and will gradually be upset, and zinc brass will be formed on the surface, and the surface resistance will gradually increase, which will lead to abnormal changes in the welding curve and affect the welding points Quality, in the actual production process, the electrode cap on the welding torch is often ground and replaced to ensure the quality of the solder joints. In the actual use process, the process of grinding and replacing the electrode cap is as follows: grinding times 1, repair Grinding times 2,..., grinding times 24, replace the electrode cap. The repeated grinding of the electrode cap will have a series of effects on welding, which will affect the welding quality and increase the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com