Vehicle-mounted liquid crystal screen light guide plate defect visual detection method based on target detection network

A target detection and visual detection technology, applied in the field of image recognition, can solve the problems of unbalanced positive and negative sample detection rate and detection efficiency of small defects, speed up training and reasoning, reduce resource parameters and resource consumption, and improve detection. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

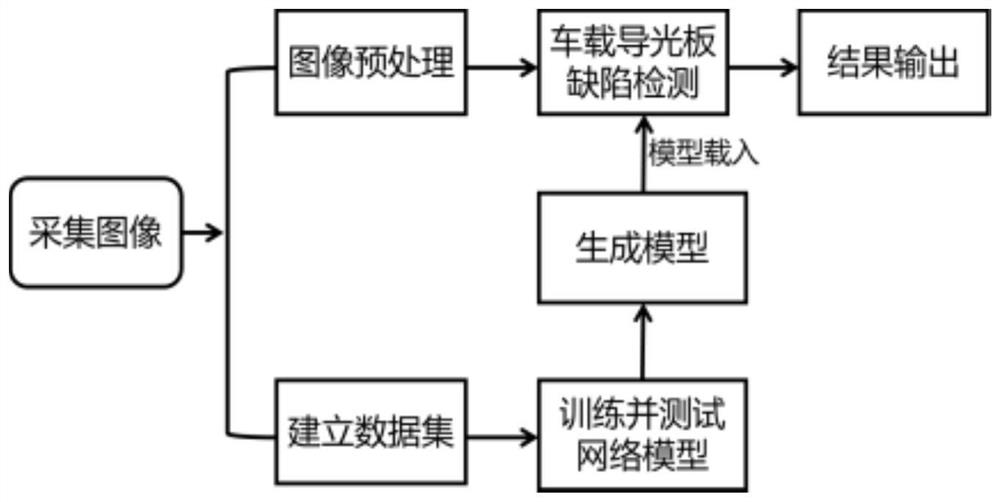

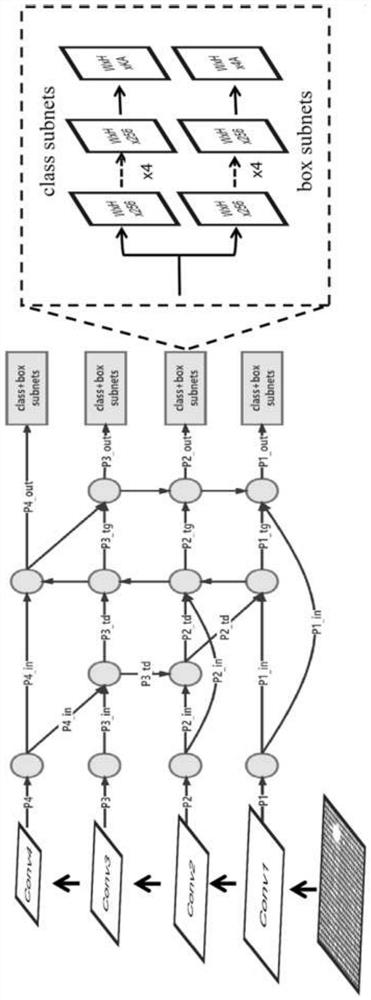

[0041] Example 1, a visual detection method of a vehicle liquid crystal screen based on a target detection network, such as Figure 1-5 As shown, including the following process:

[0042] Step 1, collect light guide

[0043] At the end of the car navigation light guide plate, the light guide plate image acquisition device is provided, and the light guide plate image acquisition device is image acquisition with a 16K wire array camera, and then transmits the acquired light guide plate image to the host computer;

[0044] Step 2, image pretreatment

[0045] The collected light guide plate image contains the background area, using threshold segmentation techniques to remove the background contained in the collected light guide plate image to obtain the regional image of the light guide plate ROI, further enhance the detection efficiency;

[0046] Then, the area image of the extracted light guide plate ROI is cut into a small image of the size of H × W × 1, wherein between the adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com