Intelligent production mobile phone module manufacturing method

A manufacturing method and technology for mobile phone modules, which are applied to manufacturing tools, machine tools suitable for grinding workpiece edges, telephone structures, etc., can solve problems such as product quality decline, pass rate decline, and low photoresist viscosity. Achieve the effect of reducing grinding work, improving product qualification rate and increasing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

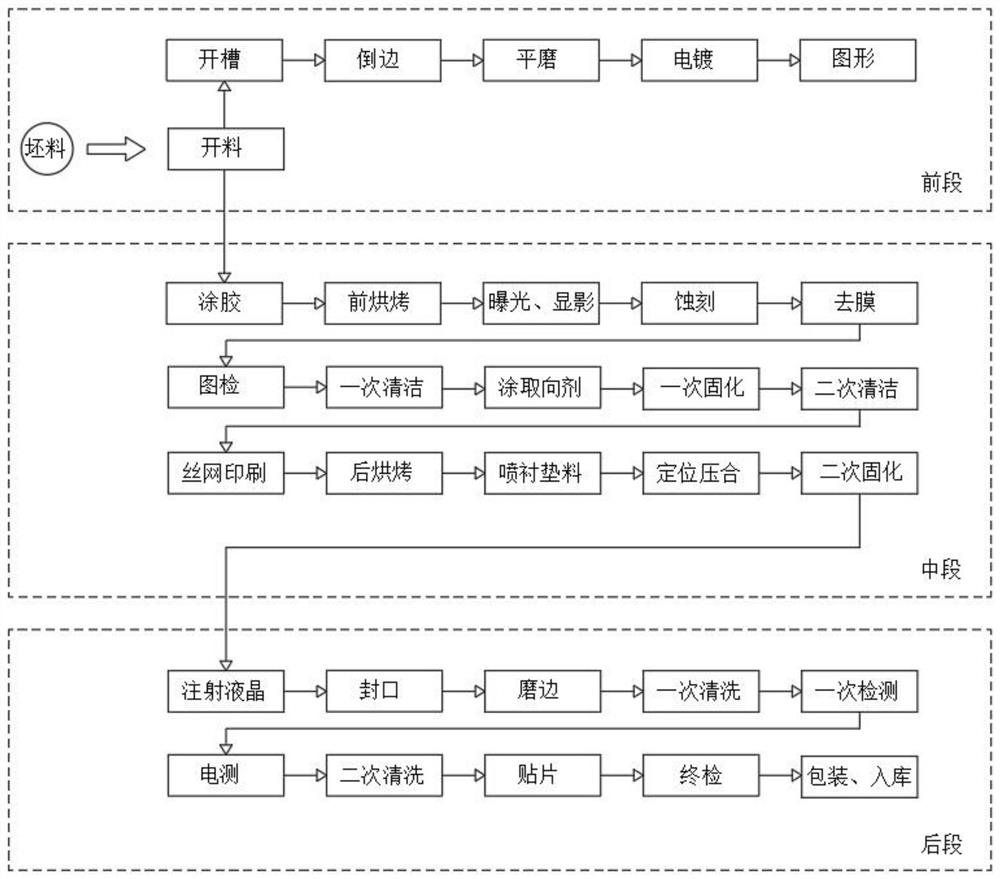

[0042] Such as figure 1 As shown, a mobile phone module manufacturing method for intelligent production, the method includes a front section, a middle section and a back end, and the front end method includes the following steps:

[0043] Step 1: cutting, take ITO glass as the blank, cut the blank into a semi-finished material larger than the required size of the product, and then transfer to the next process for production;

[0044] Step 2: Grooving, the semi-finished material is grooved according to the size smaller than the product requirements, and the mobile phone speaker groove and key groove are opened;

[0045] Step 3: chamfering, chamfering, and chamfering according to a size larger than the required size of the product to form a rounded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com