Preparation method of flavor for coffee cigarettes and application

A technology for tobacco flavor and coffee, which is applied to the field of tobacco flavor and fragrance, can solve the problems of cumbersome extraction process, low alcohol extraction rate and high preparation cost, and achieves simple extraction process, obvious sweetness and roasted aroma, and production energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

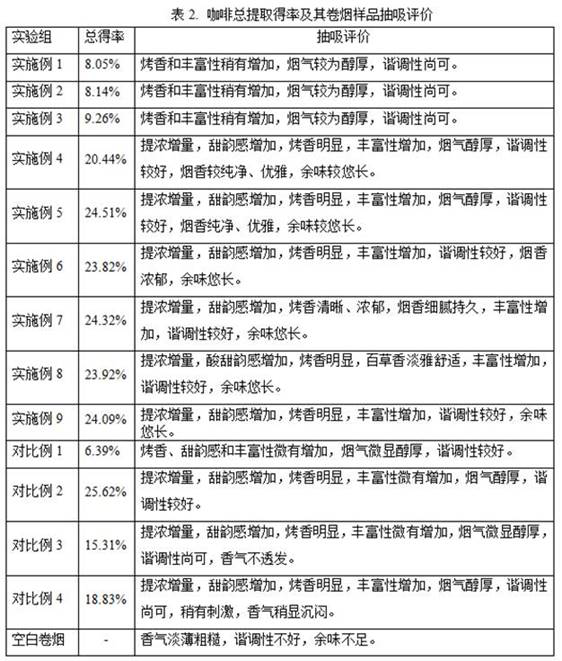

Examples

Embodiment 1

[0031] A method for preparing coffee spices for tobacco, comprising the following steps:

[0032] Choose 53% Fen-flavor liquor and first-class Arabica coffee green beans produced in Tengchong, Yunnan.

[0033]The green coffee beans were roasted at 175°C for 12 minutes, and then rapidly cooled at 5°C to obtain coffee beans.

[0034] Crush the coffee beans to 20-30 mesh and white wine according to the ratio of 1:6, the extraction temperature is 55°C, the rotation speed is 60rpm, and the extraction time is 45min. Filter through a 300-mesh filter cloth to obtain wine extract and residue. Then the wine extract is concentrated under reduced pressure at a temperature of 60° C. and a pressure of 60-150 mbar to a solid content of 60 percent to obtain a flavor for tobacco.

[0035] Weigh the obtained tobacco flavor according to 3‰ of 0.8g of each blank shredded tobacco, dilute it with 5ml of absolute ethanol, inject it into the blank cigarette with a flavor and fragrance injection mac...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0038] The obtained wine extract was refrigerated at 5°C for 3 hours and then precipitated, and then the precipitate was removed with a 400-mesh filter cloth, and the remaining wine extract filtrate was concentrated under reduced pressure and used as a flavoring for tobacco.

Embodiment 3

[0040] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

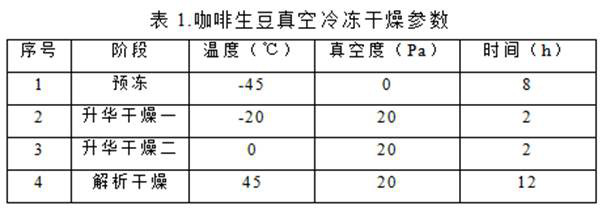

[0041] The green coffee beans were vacuum freeze-dried according to the parameters in Table 1, and then roasted, crushed, and mixed with liquor for extraction.

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com