Fixed-length cutting and efficient heat dissipation device for ceramic steel pipes

A cooling device and fixed-length technology, which is applied in the field of ceramic steel pipes, can solve the problems of inability to achieve continuous equal-length cutting, length error of ceramic steel pipes, troublesome cutting process, etc., so as to ensure cutting efficiency and cutting quality, ensure stability, increase The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

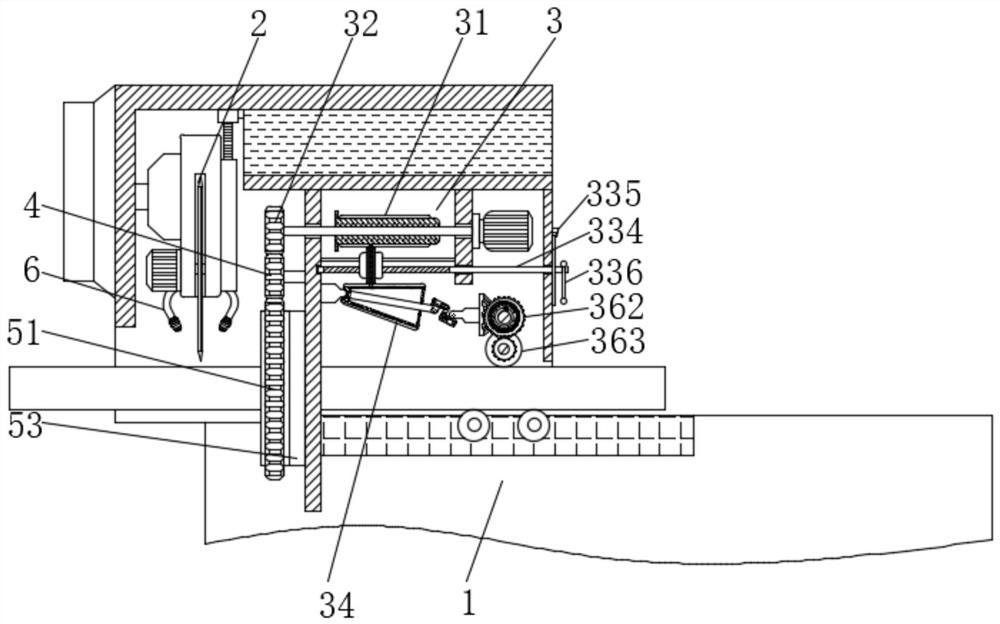

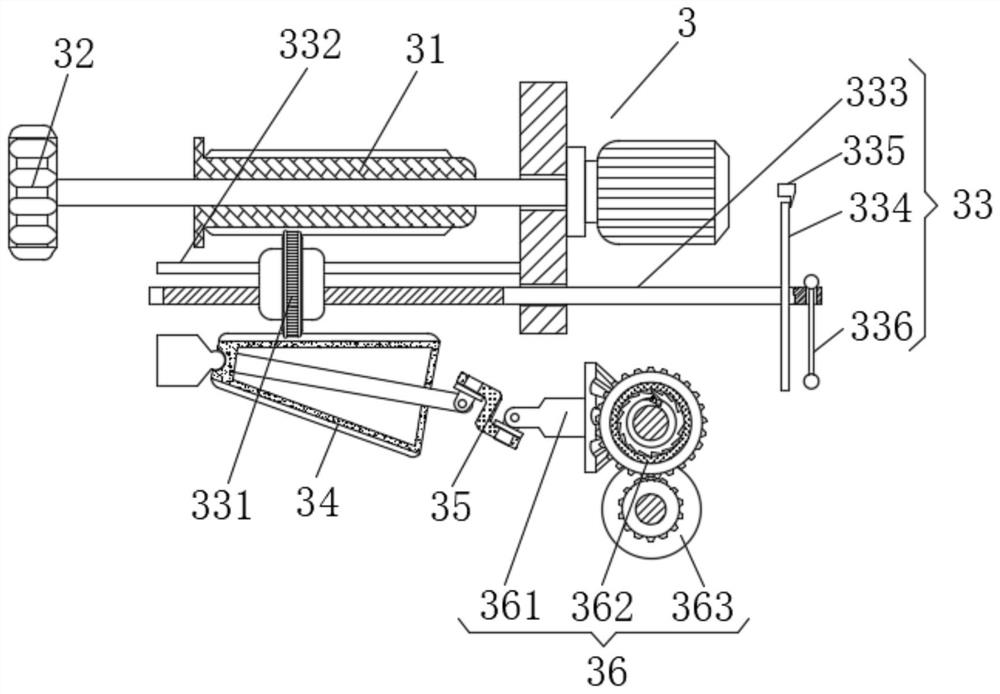

[0027] see Figure 1-2 , a fixed-length cutting and high-efficiency cooling device for ceramic steel pipes, including a machine tool 1 and a cutting head 2, a fixed-length mechanism 3 is arranged inside the machine tool 1, and the fixed-length mechanism 3 includes a tooth column 31, and the external fixing of the tooth column 31 The main gear 32 is connected, and the outside of the gear column 31 is provided with an adjustment mechanism 33, and the outside of the adjustment mechanism 33 is provided with a round table wheel 34, and the outside of the round table wheel 34 is hinged with a coupling 35, and the outside of the shaft coupling 35 is provided with a propulsion mechanism 36, the outer meshing connection of the main gear 32 is connected with the connecting gear 4, and the bottom of the connecting gear 4 is provided with a clamping mechanism 5.

[0028] Wherein, the outside of tooth column 31 is provided with clamping motor, and adjustment mechanism 33 comprises connecti...

Embodiment 2

[0031] see Figure 1-2 , a fixed-length cutting and high-efficiency cooling device for ceramic steel pipes, including a machine tool 1 and a cutting head 2, a fixed-length mechanism 3 is arranged inside the machine tool 1, and the fixed-length mechanism 3 includes a tooth column 31, and the external fixing of the tooth column 31 The main gear 32 is connected, and the outside of the gear column 31 is provided with an adjustment mechanism 33, and the outside of the adjustment mechanism 33 is provided with a round table wheel 34, and the outside of the round table wheel 34 is hinged with a coupling 35, and the outside of the shaft coupling 35 is provided with a propulsion mechanism 36, the outer meshing connection of the main gear 32 is connected with the connecting gear 4, and the bottom of the connecting gear 4 is provided with a clamping mechanism 5.

[0032] Wherein, the outside of tooth column 31 is provided with clamping motor, and adjustment mechanism 33 comprises connecti...

Embodiment 3

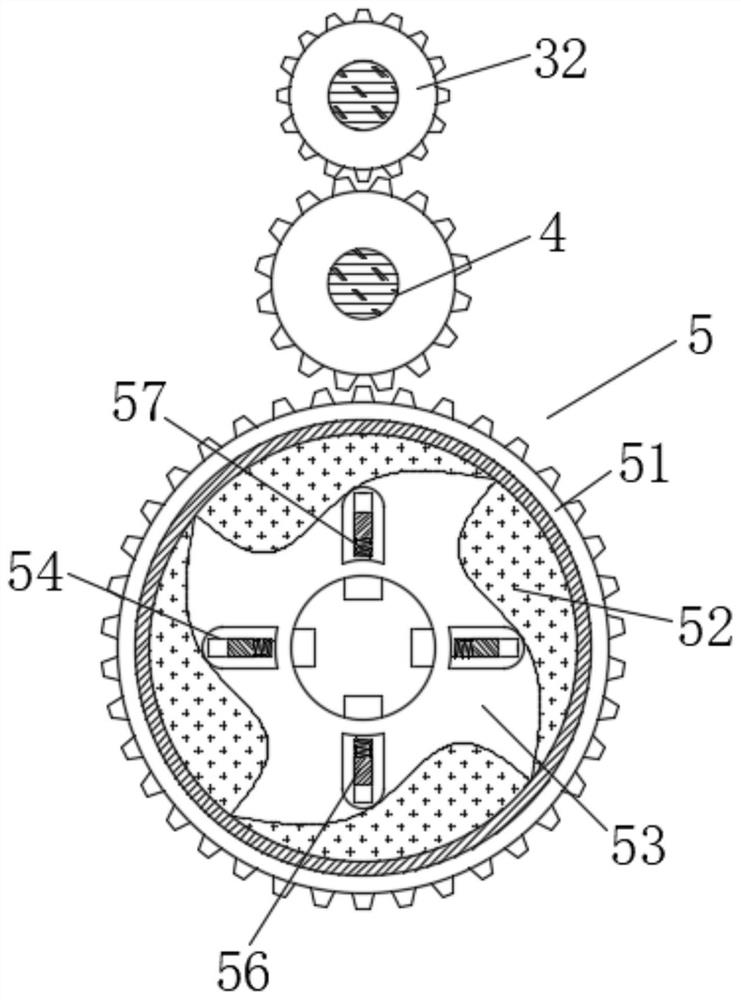

[0036] see Figure 1-4 , a fixed-length cutting and high-efficiency cooling device for ceramic steel pipes, including a machine tool 1 and a cutting head 2, a fixed-length mechanism 3 is arranged inside the machine tool 1, and the fixed-length mechanism 3 includes a tooth column 31, and the external fixing of the tooth column 31 The main gear 32 is connected, and the outside of the gear column 31 is provided with an adjustment mechanism 33, and the outside of the adjustment mechanism 33 is provided with a round table wheel 34, and the outside of the round table wheel 34 is hinged with a coupling 35, and the outside of the shaft coupling 35 is provided with a propulsion mechanism 36, the external meshing connection of the main gear 32 is connected with the connecting gear 4, and the bottom of the connecting gear 4 is provided with a clamping mechanism 5.

[0037] Wherein, the clamping mechanism 5 includes an outer ring gear 51, the outer ring gear 51 is meshed with the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com