Manufacturing device and process for inner tube of double-layer cooling tube

A technology for manufacturing devices and cooling pipes, which is applied in the field of welded pipe manufacturing, can solve problems such as overburning, and achieve the effects of improving service life, ensuring contact area, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

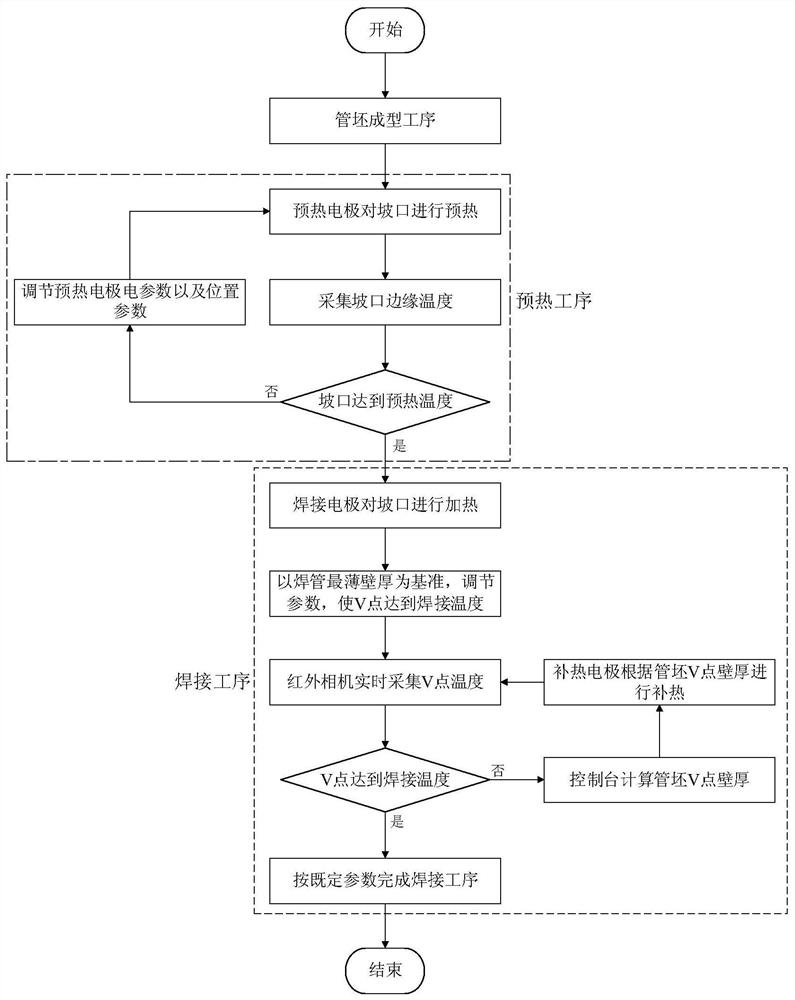

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

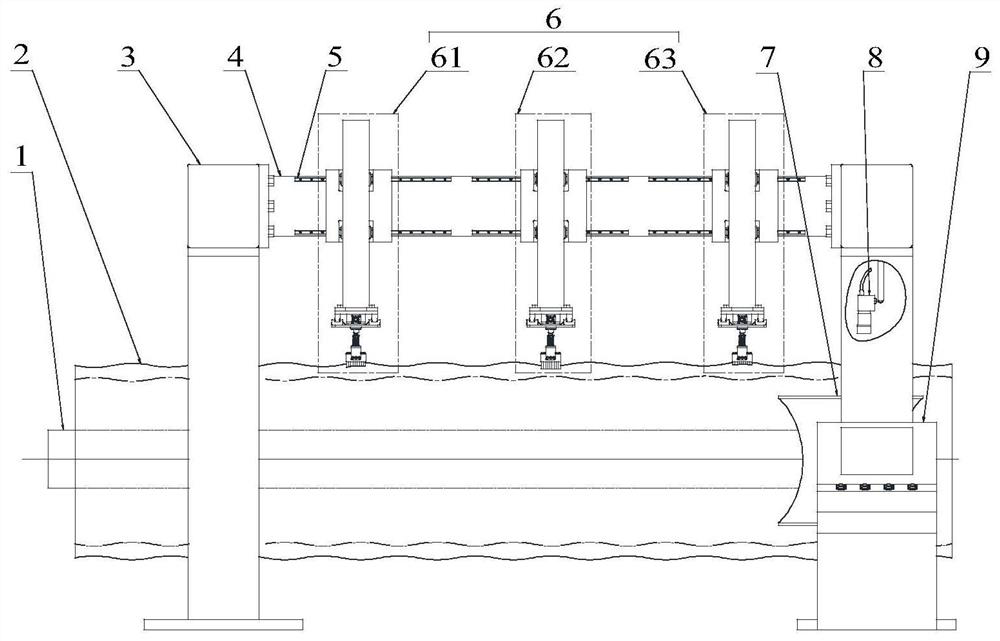

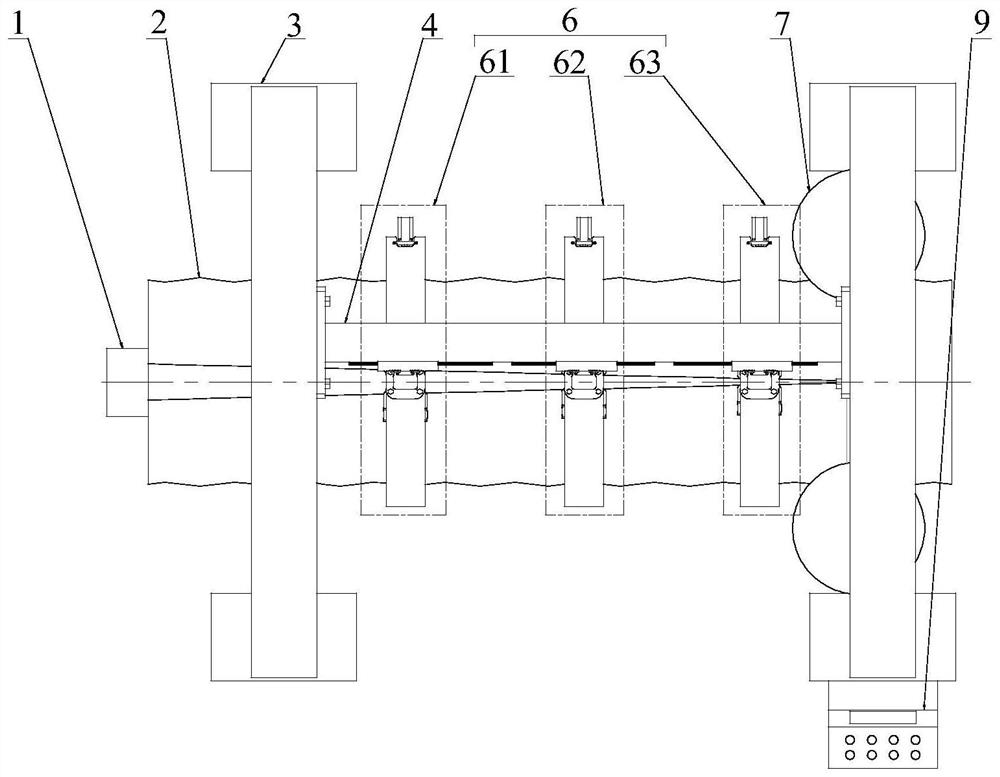

[0039] Manufacturing equipment for inner tubes of double-layer cooling tubes, such as figure 2 and image 3 As shown, it includes a magnet bar 1, a tube blank 2, a gantry 3, a beam 4, a first guide rail 5, an electrode 6, a squeeze roller 7, an infrared camera 8 and a console 9, etc. The number of the gantry 3 is two, And connected through the beam 4, the beam 4 is provided with three groups of first guide rails 5 (the number is six), each group of the first guide rails 5 is slidably installed with electrodes 6, and below the beam 4 is the tube blank 2, which is installed coaxially inside the tube blank 2. There is a magnetic bar 1, squeeze rollers 7 are installed on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com