Electrophoretic coating water-based color paste and preparation method thereof

A technology for water-based colorants and electrophoretic coatings, which can be used in electrophoretic coatings, pigment pastes, coatings, etc., and can solve the problems of cumbersome processes, unfriendly environmental protection of oil-based colorants, and inaccurate color matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

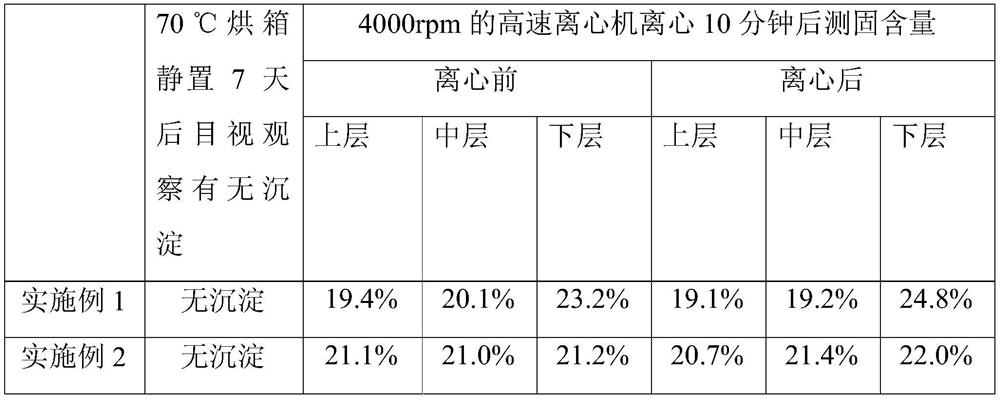

Examples

Embodiment 1

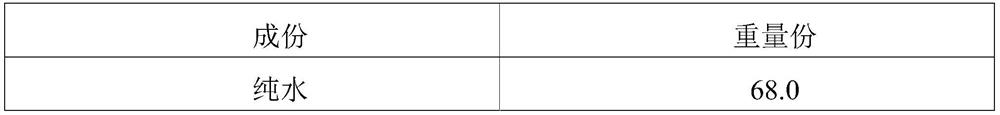

[0031] The raw material composition ratio of the electrophoretic paint water-based color paste used in the present embodiment is as follows:

[0032] ingredients parts by weight pure water 65.0 Ethylene glycol butyl ether 5.0 ZetaSperse 3800 1

18.0 red toner 2

13.0

[0033] 1: Evonik products. 2: Clariant product F5RK-CN09.

[0034] The preparation process is as follows:

[0035] (1) Put pure water, butyl glycol ether, and ZetaSperse3800 dispersant into a 1L double-layer stainless steel dispersion tank, start the mixer, and stir at a speed of 200rpm for 15 minutes or evenly to obtain a dispersion.

[0036] (2) Increase the rotation speed to 300rpm, slowly add the red toner into the tank, so that the red toner is completely dissolved in the dispersion, and continue to stir for 1 hour to obtain a pre-dispersed color paste.

[0037] (3) Slowly add 150g of plastic beads with a particle size of 0.6-0.7mm into the tank. At this time, i...

Embodiment 2

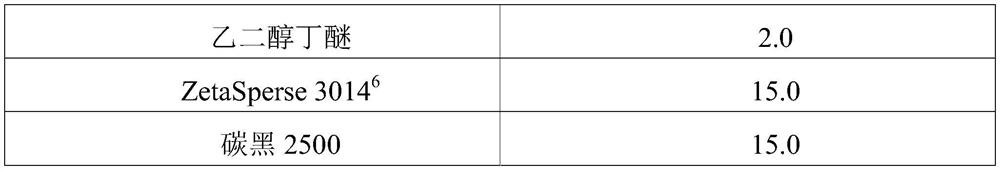

[0040] The raw material composition ratio of the electrophoretic paint water-based color paste used in the present embodiment is as follows:

[0041] ingredients parts by weight pure water 60.0 Ethylene glycol butyl ether 10.0 ZetaSperse 3800 15.0 yellow toner 3

15.0

[0042] 3: Clariant product HR02-CN09.

[0043] The preparation process is as follows:

[0044] (1) Put pure water, butyl glycol ether, and ZetaSperse3800 dispersant into a 1L double-layer stainless steel dispersion tank, start the mixer, and stir at a speed of 200rpm for 15 minutes or evenly to obtain a dispersion.

[0045] (2) Increase the rotation speed to 300rpm, slowly add the yellow toner into the tank to completely dissolve the yellow toner into the dispersion, and keep stirring for 1 hour to obtain a pre-dispersed color paste.

[0046] (3) Slowly add 150g of plastic beads with a particle size of 0.6-0.7mm into the tank. At this time, increase the speed to 800rp...

Embodiment 3

[0049] The raw material composition ratio of the electrophoretic paint water-based color paste used in the present embodiment is as follows:

[0050] ingredients parts by weight pure water 70.0 Propylene Glycol Methyl Ether 4.0 ZetaSperse 3800 20.0 blue toner 4

15.0

[0051] 4: Clariant product BLUE BG.

[0052] The preparation process is as follows:

[0053] (1) Put pure water, propylene glycol methyl ether, and ZetaSperse3800 dispersant into a 1L double-layer stainless steel dispersion tank, start the mixer, and stir at a speed of 200rpm for 15 minutes or evenly to obtain a dispersion.

[0054] (2) Increase the rotation speed to 300rpm, slowly add the blue toner into the tank, so that the blue toner is completely dissolved in the dispersion, and keep stirring for 1 hour to obtain a pre-dispersed color paste.

[0055] (3) Slowly add 150g of plastic beads with a particle size of 0.6-0.7mm into the tank. At this time, increase the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com