CSIPs-steel composite structure energy consumption type anti-seismic joint

A combined structure and energy-consuming technology, applied in the direction of earthquake resistance, building components, building types, etc., can solve problems such as poor seismic performance, achieve the effect of convenient installation and improve earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

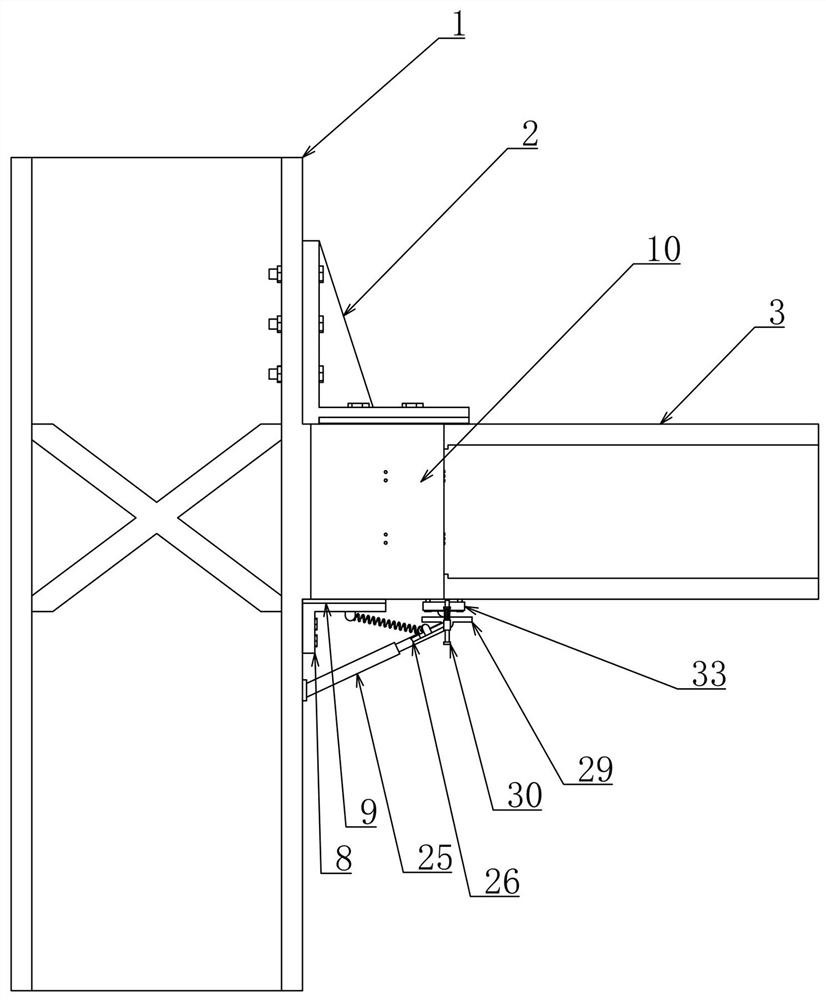

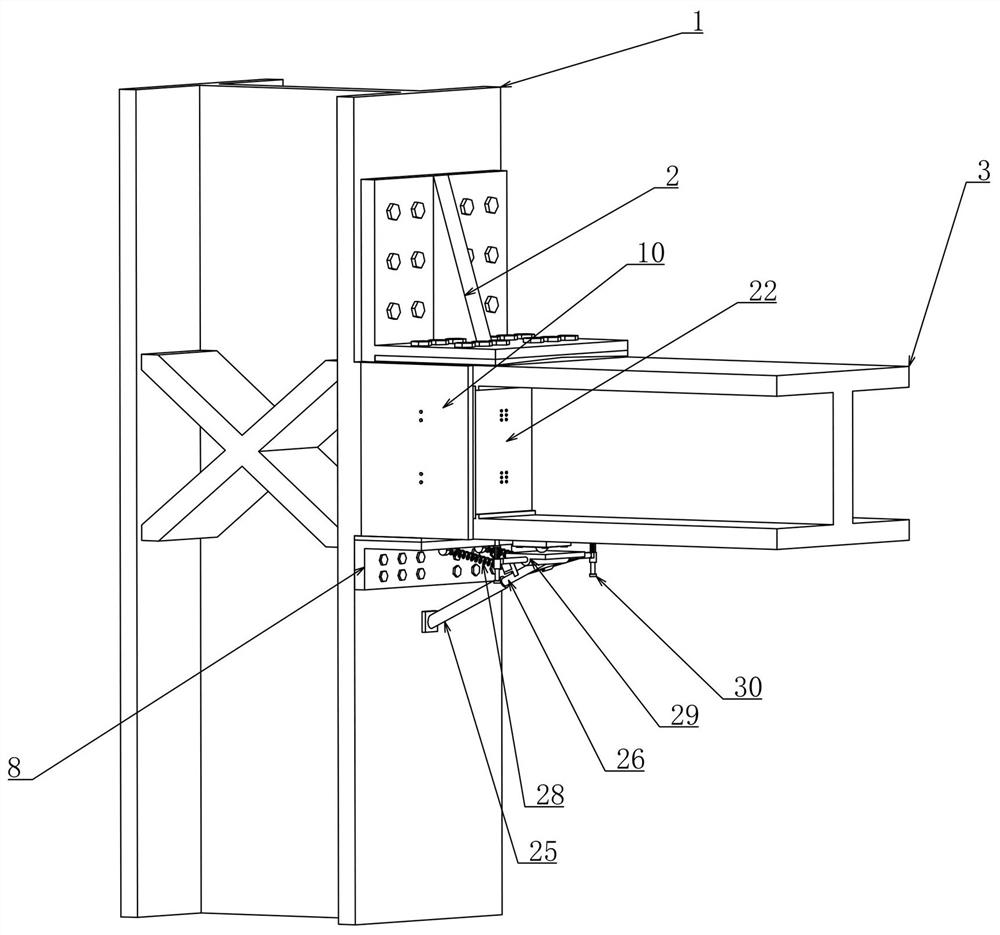

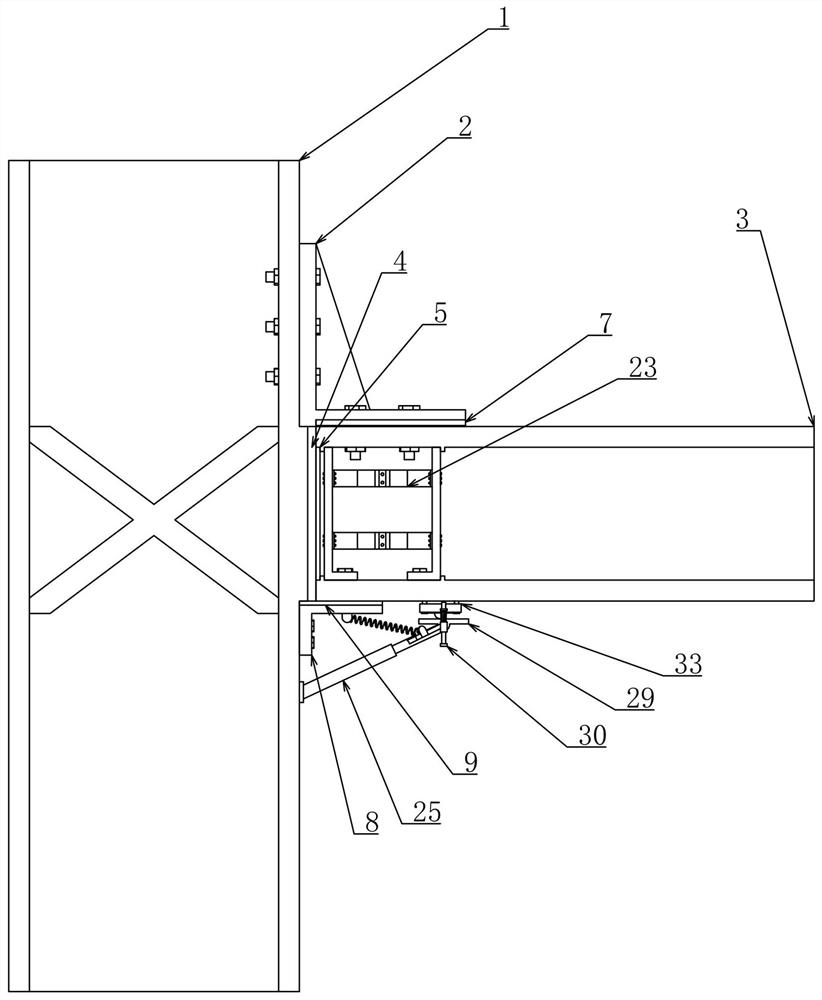

[0028] Embodiment one, combined with the attached Figure 1-4 , a CSIPs-steel composite structure energy dissipation type seismic node, comprising a vertically arranged beam column 1, characterized in that a connecting plate 2 is fixedly connected horizontally on the beam column 1, and the bottom of the connecting plate 2 is connected by bolts A horizontally arranged beam 3, a first action plate 4 is arranged between the beam 3 and the beam column 1 to absorb the energy generated by the vibration of the beam column 1, and the first action plate 4 is made of alumina ceramics by default material, which has high hardness and can resist compression to a large extent, so it can be placed between the beam 3 and the beam column 1 as a connecting piece to play a certain connection role, but the tensile strength of this board is not enough at the same time, and it is prone to brittleness Fracture, when an earthquake occurs, the beam and column 1 will shake. At this time, the first acti...

Embodiment 2

[0029] Embodiment two, on the basis of embodiment one, in conjunction with the attached Figure 1-9A protection device is also fixedly connected to the connection plate 2, the protection device includes a strut 11 fixedly connected to the connection plate 2 in the transverse direction, and a fixed cylinder 12 is vertically fixedly connected to the strut 11, the The fixed cylinder 12 has a built-in fixed rod 13 fixedly connected to the beam 3. The diameter of the inner hole of the fixed cylinder 12 is larger than the diameter of the fixed rod 13. The upper end of the fixed rod 13 is fixedly connected with a fixed column 14. The fixed column The diameter of 14 is greater than the diameter of the inner circular hole of the fixed cylinder 12, satisfying that under the action of other external forces, the crossbeam 3 will be suspended on the strut 11 through the cooperation relationship between the fixed rod 13 and the fixed column 14 and the fixed cylinder 12. The cylinder 12 is s...

Embodiment 3

[0030] Embodiment three, on the basis of embodiment one, in conjunction with the attached Figure 1-11 , the force component device includes a pair of partitions 22 vertically fixedly connected in the groove of the beam 3, there is a gap between the partitions 22 close to the second action plate 5 and the second action plate 5, two Two elastic plates 23 arranged at vertical intervals are fixedly connected horizontally between the partitions 22, and the elastic plates 23 and the side plates 10 are fixedly connected by a transmission rod 24. Preset, the partitions 22 adopt The lower end is fixedly connected to the beam 3 with bolts, and the upper end is not fixed. The elastic plate 23 fixedly connected between the two partitions 22 can convert the force of the side plate 10 on the longitudinal direction of the cross beam 3 into the force of the elastic plate 23 on the partition. The force in the transverse direction of the plate 22, and the transverse force generated by the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com