Portable extremely-soft coal rock compaction type sample manufacturing device and manufacturing method

A technology for manufacturing equipment and soft coal rock, which is applied in the field of laboratory coal rock sample manufacturing equipment, and achieves the effects of easy popularization and application, convenient processing, good uniformity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

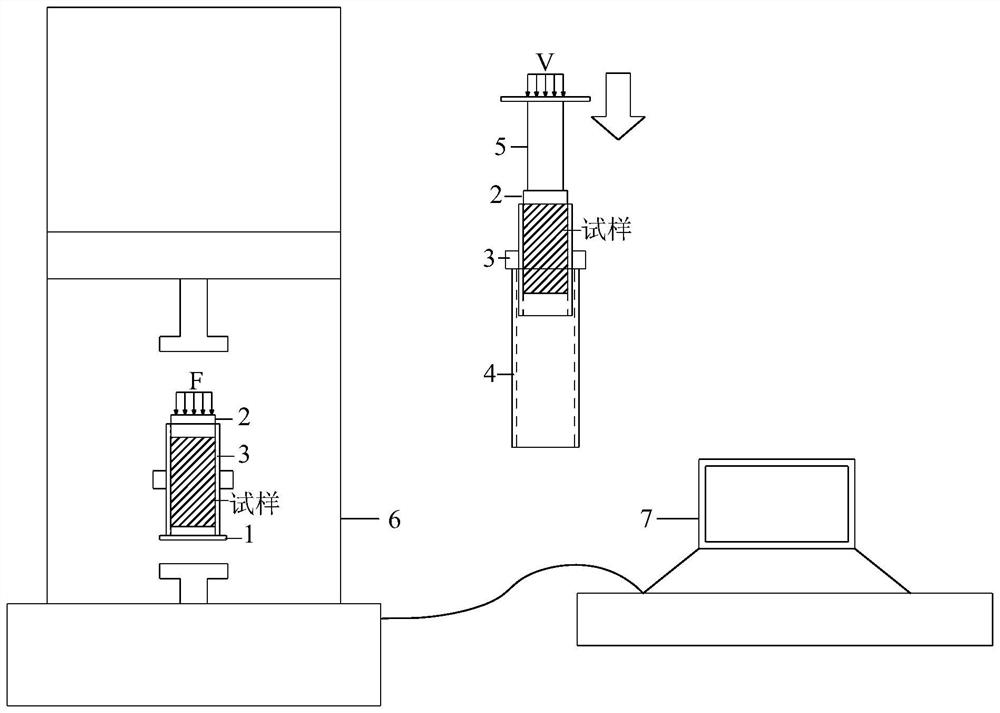

[0035] The laboratory is mainly carried out by making standard samples, which will be described in connection with the drawings, and the present invention will be described in connection with the accompanying drawings.

[0036] like figure 1 As shown, an easy-to-use soft coal rock is compactive sample production apparatus, including a sample system, a demolding system, and a servo testing machine 6 and a control system 7 for applying a sampling pressure and a sample sample. Composition of sample production devices. Among them, the sample system includes a thin-walled tube article 3 and a fitting, and the fitting is a convex column base 1 and a circular cake press 2, and the assembly form of the sampling system is: the ingredients of the sample pass through the susceptor 1 and The head 2 is quantified to press the molded molding in the sampler 3. The demolding system includes a tubular release chamber 4, a T-shaped transmission rod 5, and a circular cake-shaped press 2, and the fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com