Probe driving structure of adjustable probe card device

A driving structure and probe card technology, which is applied in the field of probe cards, can solve problems such as poor contact, inconsistent height, deviation of probe height and pad or bump height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

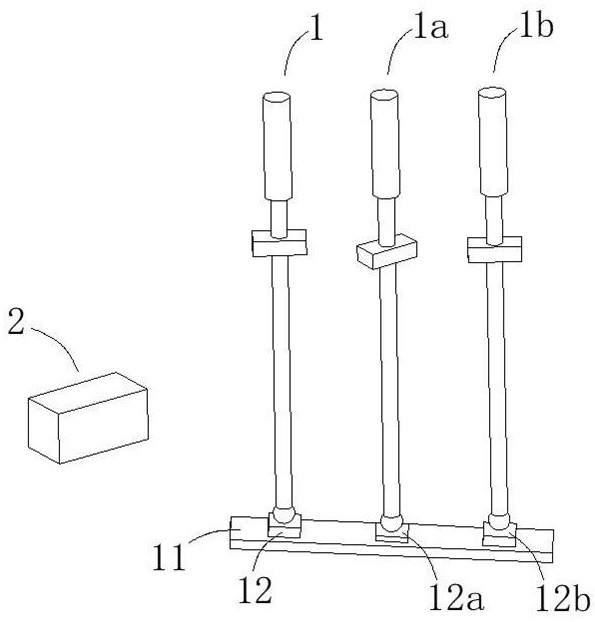

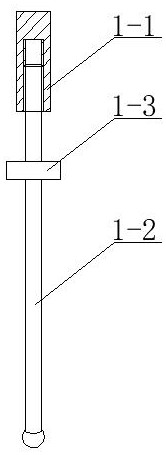

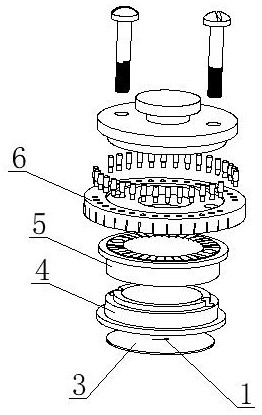

[0053] combine figure 1 As shown, an adjustable probe card device disclosed in this embodiment includes: a probe unit 1, a moving magnet 2, a probe card 3, a seat ring 4, a collar 5, a guide ring 6 and a probe wire 7, Several probe units 1 are arranged in an array, and a moving magnet 2 is arranged around the outer side of the probe unit array. The moving magnet 2 can move around the probe unit array, and a magnetic pole of the moving magnet 2 points to the probe unit during the movement. Array; the probe unit array is composed of probe unit 1, which is driven down by the micro-displacement of the probe station, and contacts with the bump 12 on the surface of the wafer 11 to realize the connection. After the high bump 12b contacts the probe unit 1b , at this time, the low bump 12a cannot be in contact with the probe unit 1a. By rotating the moving magnet 2 around a probe unit array, it moves around the probe unit array, and adjusts the probe unit 1a to move down, so that the p...

specific Embodiment approach 2

[0062] The following is an embodiment of a probe driving structure of an adjustable probe card device. The probe driving structure can be implemented alone, or can be used as a key structure of an adjustable probe card device disclosed in the first embodiment.

[0063] combine Figure 6 to Figure 8 As shown, a probe driving structure of an adjustable probe card device is used to drive the moving magnet 2 to rotate around the probe unit array, which can realize the clockwise and counterclockwise rotation of the moving magnet 2, and can use the moving magnet when needed 2. Move the moving magnet 2 to the vicinity of the probe unit array, and move the moving magnet 2 to a position away from the probe unit array when the moving magnet 2 is not needed to avoid the influence of the magnetic force.

[0064] The probe driving structure includes: a connecting frame 8-1, a damping disc 8-2, an external gear 8-3, an internal gear 8-4, a driving tooth 8-5 and a driving motor 8-6, and the ...

specific Embodiment approach 3

[0071] The following is an embodiment of a probe adjustment member of an adjustable probe card device. The probe driving device can be implemented alone, or can be used as a key structure of an adjustable probe card device disclosed in the first embodiment.

[0072] combine Figure 9 to Figure 11 As shown, a probe adjustment part of an adjustable probe card device is used to drive the moving magnet 2 to rotate around the probe unit array, which can realize the clockwise and counterclockwise rotation of the moving magnet 2, and can use the moving magnet when needed 2. Move the moving magnet 2 to the vicinity of the probe unit array, and move the moving magnet 2 to a position away from the probe unit array when the moving magnet 2 is not needed to avoid the influence of the magnetic force.

[0073] The probe driving device includes: connecting housing 9-1, driving device motor 9-2, driving wheel 9-3, transmission belt 9-4 and guide 9-5, one side of the connecting housing 9-1 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap