Explosion-proof and flame-proof battery pack for new energy automobile

A technology for new energy vehicles and battery packs, applied in battery pack parts, electric vehicles, secondary batteries, etc., can solve the problems of reducing the oxygen content inside the casing, incapable of sealing the battery pack, inconvenient heat dissipation, etc., to avoid dust , the effect of reducing temperature and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

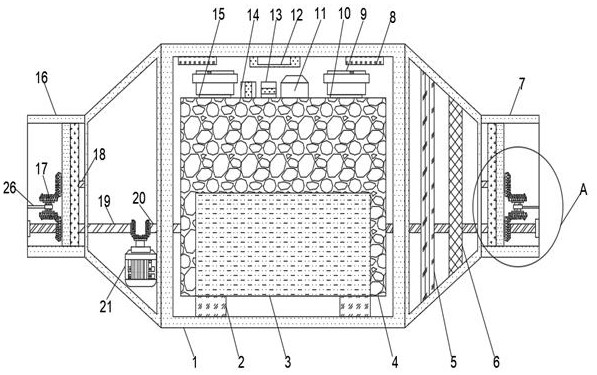

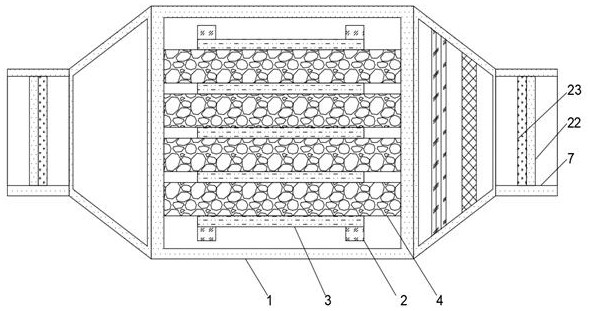

[0043] Embodiment 1: The intake pipe 7 at the right end of the housing 1 is connected to the central grid of the new energy vehicle. When the new energy vehicle is running, the external air enters the intake pipe 7 through the central grid. The vehicle travels at a certain speed, and the external air enters After the intake pipe 7, it is filtered by the filter screen 6 to remove the solid particles in the gas, and then the fine particles are removed by the activated carbon plate 5, so as to prevent impurities such as dust from entering the housing 1 and accumulating for a long time, which is not conducive to the heat dissipation of the battery board group 4 and is easy to The temperature of the battery board group 4 is increased, thereby accelerating the heat dissipation of the battery board group 4 , and as the speed of new energy vehicles continues to increase, the wind power will also continue to increase, ensuring heat dissipation and reducing resource consumption.

Embodiment 2

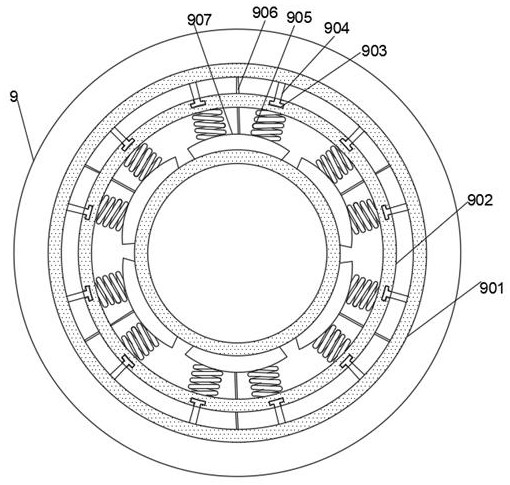

[0044] Embodiment 2: move the second pipe body 901 downward, the second pipe body 901 drives the slider 903 to move, so that the second pipe body 901 moves along the chute to the lower end of the first pipe body 902, and the second pipe body 901 drives the wire rope 906 moves downward, and the wire rope 906 drives the limiting plate 907 to squeeze the spring 905, so that the limiting plate 907 squeezes the positive pole and the negative pole of the battery plate group 4 respectively, thereby connecting the positive pole and the negative pole of the battery plate group 4 to avoid battery Dust accumulates around the positive and negative electrodes of the battery plate group 4 , causing a short circuit and preventing the connection of the positive and negative electrodes of the battery plate group 4 from loosening.

Embodiment 3

[0045] Embodiment three; when the voltage sensor 14 receives the failure of the internal circuit of the battery board group 4, the voltage sensor 14 sends a signal to the controller 12, and the controller 12 automatically starts the power protector 11, and the power protector 11 cuts off the power automatically, so that The positive and negative poles of the battery plate group 4 are disconnected to prevent the internal short circuit of the battery plate group 4 from causing a short circuit in the remaining circuits of the new energy vehicle, resulting in greater losses, and it is beneficial to protect the battery plate group 4 itself, avoiding the short circuit caused by the battery plate group 4, This causes the internal temperature of the battery plate group 4 to rise and the battery plate group 4 to burn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com