Stabilized non-enveloped virus compositions

An enveloped virus, composition technology, applied in the direction of viruses, antiviral agents, viral antigen components, etc., can solve problems such as very sensitive interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Materials and Methods

[0045] Inactivated EDS adenovirus: from HesterBiosciences Limited, Gujarat, India (www.hester.in) and from the State Veterinary Office of Sweden, Uppsala, Sweden , Uppsala) (SVA).

[0046] The iEDS virus preparation from SVA was supplied as a clear suspension of virus with a hemagglutinin assay (HA) titer of 64-128.

[0047] The virus preparation from Hester was formulated as a vaccine. In a double extraction procedure, 5% sodium cholate solution was used to extract the conceived virus from the vaccine. The clear second extract was freed of cholate by chromatography on Sephadex G-75 equilibrated with 7 mM phosphate buffer, pH 7.5. Material eluted in the void volume of the gel was assessed by HA analysis of viral activity, and active fractions were pooled.

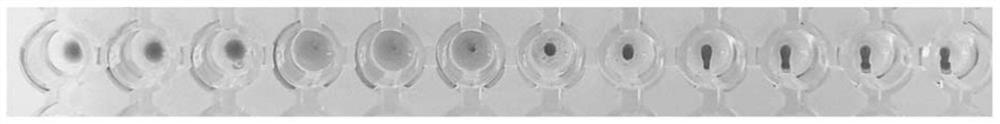

[0048] A 20% solution of 2-hydroxypropyl-β-cyclodextrin was added to either virus suspension to a final concentration of 2%. A 5 mL sample of the suspension was then applied to the nebuli...

example 2

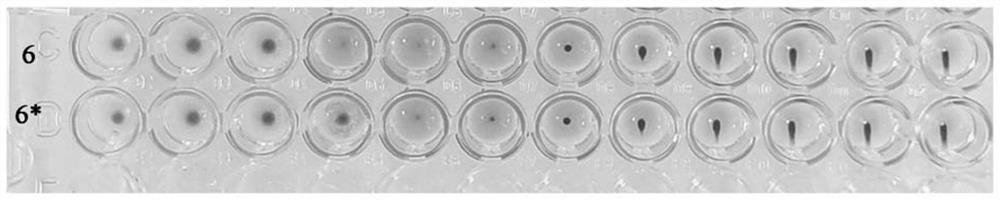

[0063] Example 2 compares EDS virus activity before and after the spray drying method and excipients according to the invention. In Example 2, inactivated EDS virus was obtained from GD animal health and the following protocol was used for the hemagglutination (HA) test of virus activity.

[0064] Hemagglutination test (HA)

[0065] equipment and materials

[0066] Use the following equipment. Benchtop centrifuge with appropriate accessories. Erythrocytes from appropriate hosts in Alsevers solution (Sigma-aldrich code A3551). Alsevers solution is composed of 4.2g / L NaCl, 8.0g / L citric acid·3Na·2H 2 O, 0.55g / L citric acid H2O, 20.5g / L D-glucose, and used as an anticoagulant / blood preservative. V-bottom 96-well plate, PBS solution

[0067] red blood cell preparation

[0068] chicken blood in AB Purchase (https: / / www.hatunalab.com / en-GB). For chicken blood, order 2ml whole blood, this should be mixed with 2ml of Alsevers solution.

[0069] Preparation of RBC solution

...

example 3

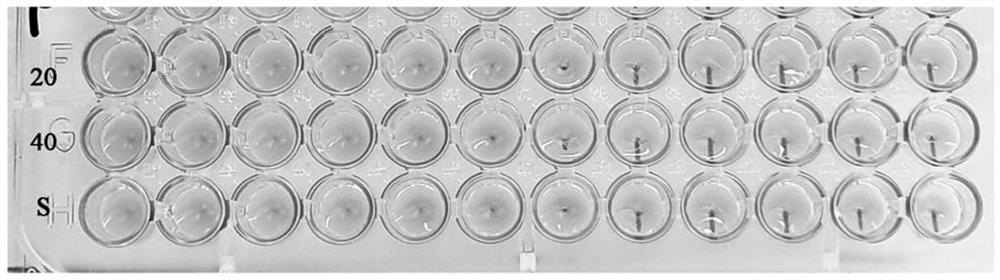

[0101] Preliminary experiments used inactivated EDS adenovirus extracts: Hyster Biosciences Ltd., Gujarat, India (see Example 1) and albumin, dextran and glycine (at similar or identical concentrations to HPBCD in previous examples, respectively). as excipient) and using the same spray drying process as defined in Examples 1 and 2. The results demonstrated that the yield after the spray drying process was high, and the HA assay maintained the viability of the virus immediately. However, compared to Examples 1 and 2 using HPBC as excipient, viral activity was significantly lost during storage at 40°C. These results confirm that the above-described Laminar Pace process for spray drying allows for drying conditions that are favorable for maintaining viral activity and yield, whereas in the given case, neither of these excipients allow the desired thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com