Non-woven fabric composite adhesive for printing as well as preparation method and application of non-woven fabric composite adhesive

A technology of non-woven fabrics and composite glue, which is applied in the field of composite glue to achieve good bonding performance, prevent pollution, and increase the drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

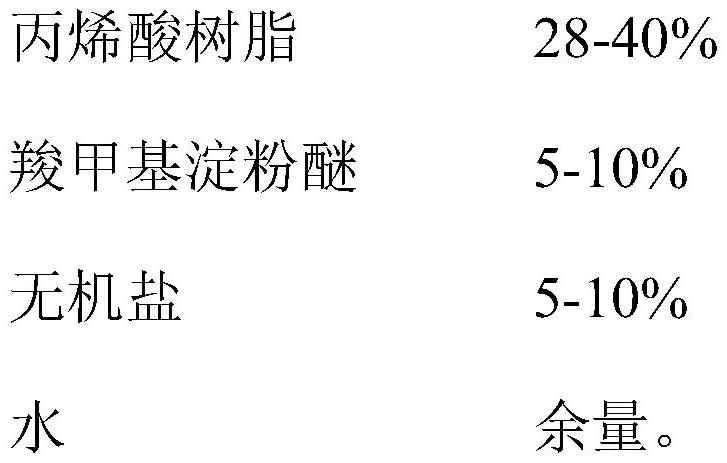

[0037] The non-woven composite adhesive for printing of the present embodiment comprises the following components by weight percentage:

[0038]

[0039] Among them, the viscosity of acrylic resin CS503 at 25°C is 800mpa·s, the degree of substitution of carboxymethyl starch ether is 0.5, the viscosity at 25°C is 2000mpa·s, and the inorganic salt is calcium phosphate.

Embodiment 2

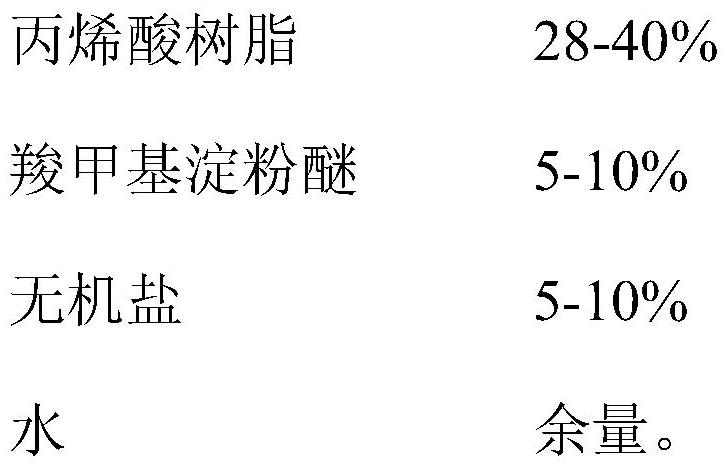

[0041] The non-woven composite adhesive for printing of the present embodiment comprises the following components by weight percentage:

[0042]

[0043] Among them, the viscosity of acrylic resin CS503 at 25°C is 800mpa·s, the degree of substitution of carboxymethyl starch ether is 0.5, the viscosity at 25°C is 2000mpa·s, and the inorganic salt is calcium phosphate.

Embodiment 3

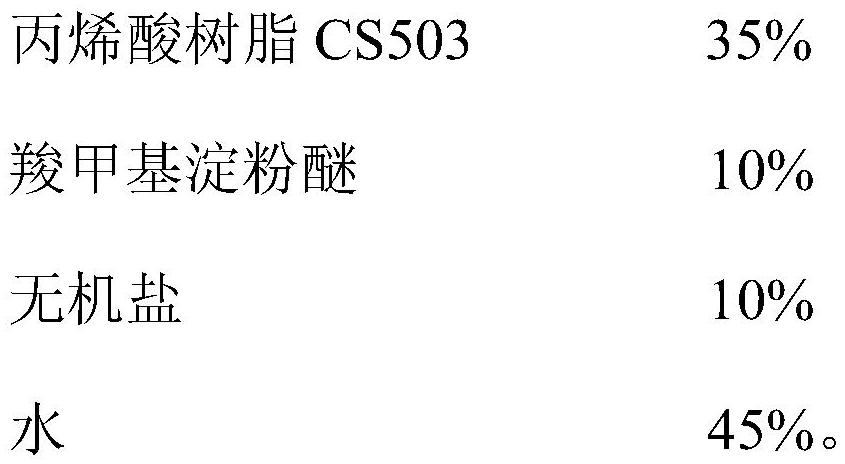

[0045] The non-woven composite adhesive for printing of the present embodiment comprises the following components by weight percentage:

[0046]

[0047] Among them, the viscosity of acrylic resin CS503 at 25°C is 800mpa·s, the degree of substitution of carboxymethyl starch ether is 0.5, the viscosity at 25°C is 2000mpa·s, and the inorganic salt is calcium phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com