Drill jumbo drilling method, drilling quality evaluation method and system, as well as drill jumbo

A rock drilling jumbo, quality evaluation technology, applied in drilling equipment and methods, drilling automatic control system, measurement, etc., can solve the problem of unsatisfactory drilling quality of drilling and blasting holes, excessive tunnel contour Excavation and other problems to achieve the effect of improving construction efficiency and improving contour quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

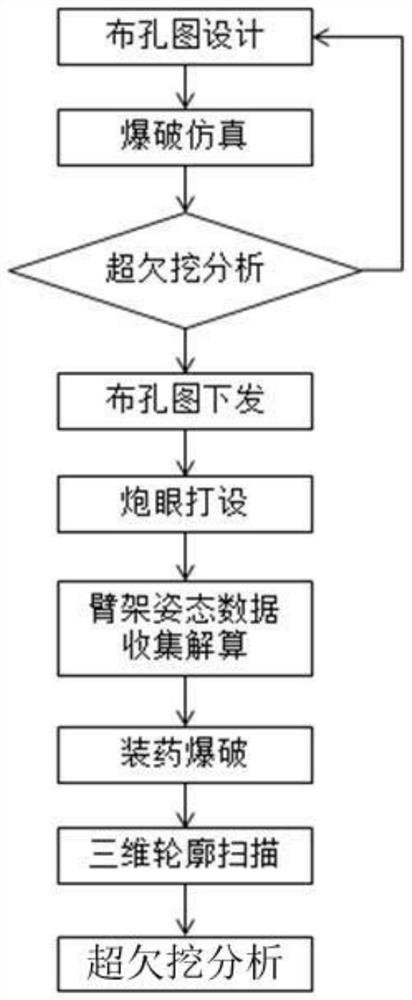

[0024] A method for evaluating the drilling quality of a rock drilling rig, comprising: obtaining a hole layout diagram and a simulation diagram of a tunnel contour after simulating blasting based on the hole layout diagram; drilling and blasting holes on the rock drilling rig according to the acquired hole layout diagram During the design operation, the attitude data of each rock drilling arm of the rock drilling rig is obtained, and then the actual drilling and blasting hole distribution map is obtained; after the blasting, the tunnel contour is scanned to obtain the actual tunnel contour map; based on the hole layout map, the actual Drilling and blasting hole distribution diagram, tunnel contour simulation diagram and actual tunnel contour diagram, conduct overbreak and underbreak analysis, and obtain analysis results, which are used to evaluate the drilling quality and blasting quality of rock drilling rigs.

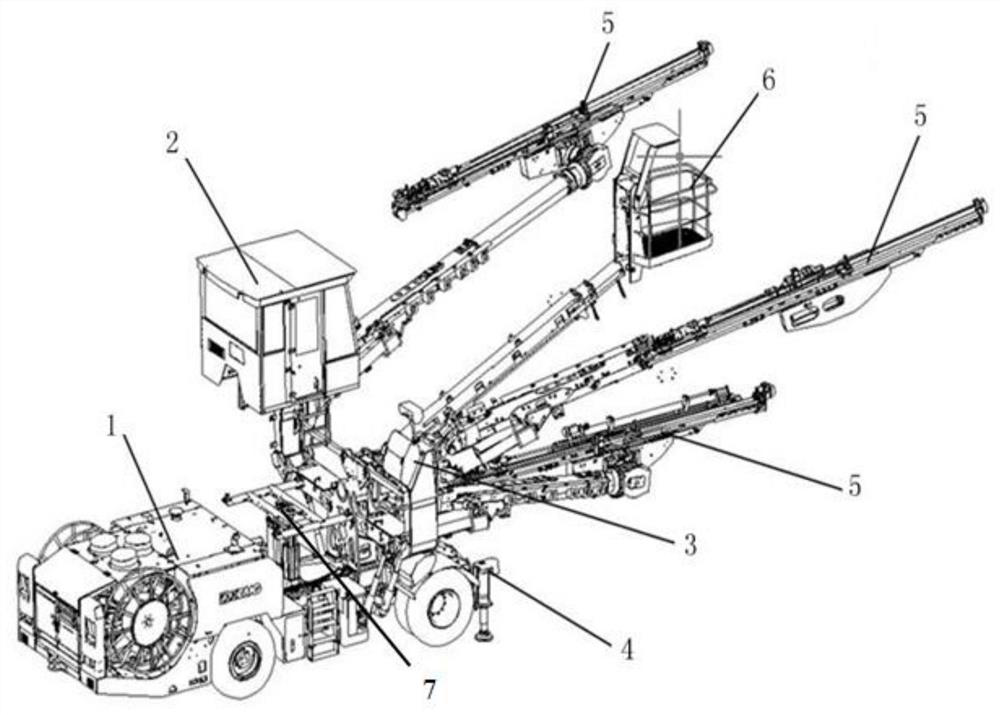

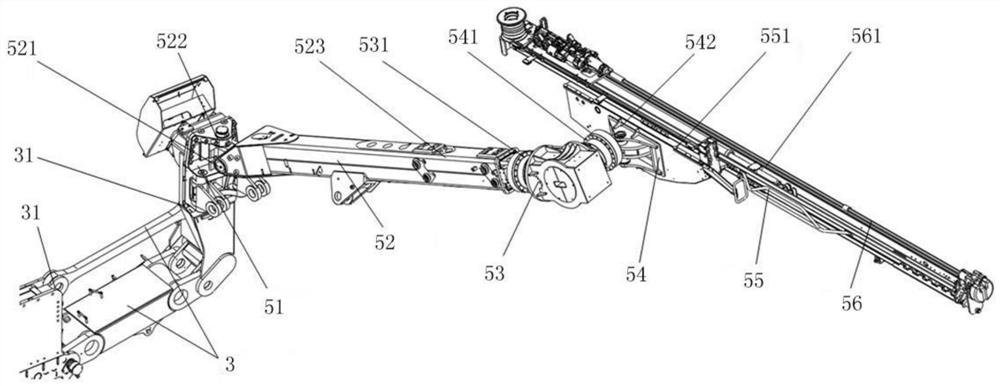

[0025] Such as Figure 1~Figure 3 As shown, the rock drilling j...

Embodiment 2

[0034] Based on the drilling rig drilling quality evaluation method described in Embodiment 1, this embodiment provides a drilling rig drilling quality evaluation system, including: a first module for obtaining a hole layout map and Figure 1 simulates the tunnel outline simulation diagram after blasting; the second module obtains the attitude data of each rock drilling arm of the rock drilling jumbo when the drilling jumbo drills and blasts holes according to the acquired hole layout diagram, and then Obtain the actual distribution map of drilling and blasting holes; the third module is used to scan the tunnel contour after blasting to obtain the actual tunnel contour map; the fourth module is used to The contour simulation diagram and the actual tunnel contour diagram are analyzed for over and under excavation, and the analysis results are obtained, which are used to evaluate the drilling quality and blasting quality of the rock drilling rig.

Embodiment 3

[0036] Based on the drilling rig drilling quality evaluation method described in Embodiment 1 and the drilling rig drilling quality evaluation system described in Embodiment 2, this embodiment provides a drilling rig drilling method, including: obtaining The hole layout diagram and the simulation diagram of the tunnel outline after the blasting simulation based on the hole layout diagram; when the rock drilling rig is drilling and blasting holes according to the obtained hole layout diagram, the attitude data, and then obtain the actual drilling and blasting hole distribution map; after the blasting, scan the tunnel profile to obtain the actual tunnel profile; based on the hole layout map, the actual drilling and blasting hole distribution map, the tunnel profile simulation map and the actual tunnel profile Figure, carry out overbreak and underbreak analysis, and obtain the analysis results; based on the analysis results, determine the key drilling and blasting holes and non-cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com