A raised type coal particle environmental protection drying equipment

A technology for drying equipment and granules, applied in non-progressive dryers, drying solid materials, drying gas layout, etc., can solve the problems of limited height, coal fragmentation, small turning range, etc., to achieve easy deformation, fast heat absorption and the effect of conducting heat and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

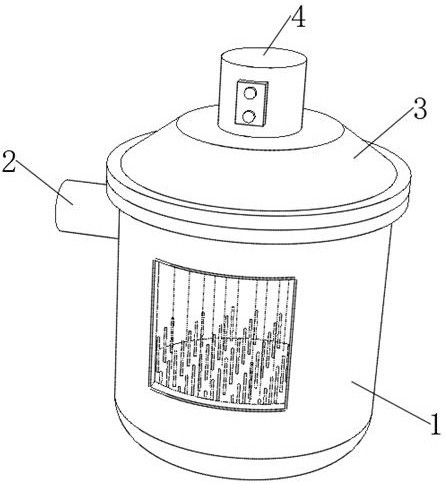

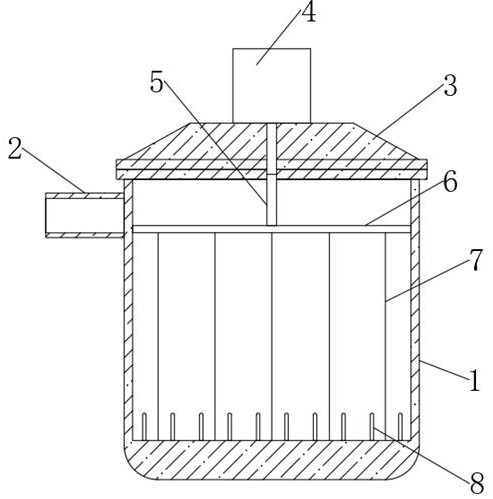

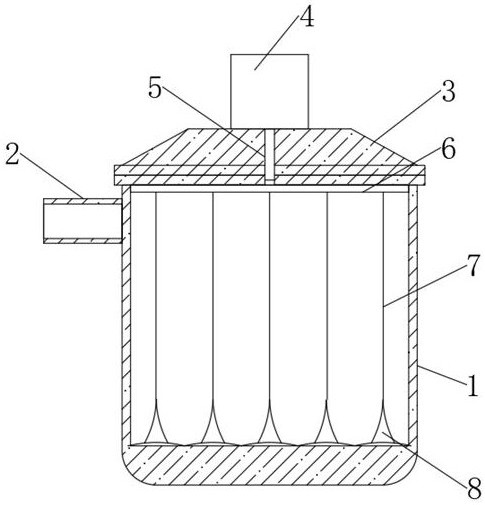

[0046] see Figure 1-4 , a raised type coal particle environmental protection drying equipment, including a drying cylinder 1, a hot air pipe 2 is installed on the side wall of the drying cylinder 1, a cover body 3 is installed on the upper end of the drying cylinder 1, a power supply box 4 is installed on the upper end of the cover body 3, and the power supply The lower end of the box 4 is electrically connected to an electric push rod 5, and the lower end of the electric push rod 5 is fixedly connected to a lifting plate 6, and the inner bottom of the drying cylinder 1 is fixedly connected to a plurality of evenly distributed drying plates 8, on which coal is laid. For particles, a linkage rod 7 is fixedly connected between the drying plate 8 and the lifting plate 6. The drying plate 8 includes a shaped plate body 81, a raised film 82 and a plurality of stretched films 83, and the raised film 82 is fixedly connected with the linkage rod 7. There is a main hole in the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com