Sample container and thermal analyzer

A technology of thermal analysis device and sample container, which is applied in thermal analysis of materials, containers, and analysis materials, etc., can solve problems such as movement, inability to observe samples, and hindrance to the observation of sample color and structure, so as to reduce thermal deformation, The effect of high-precision physical property evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

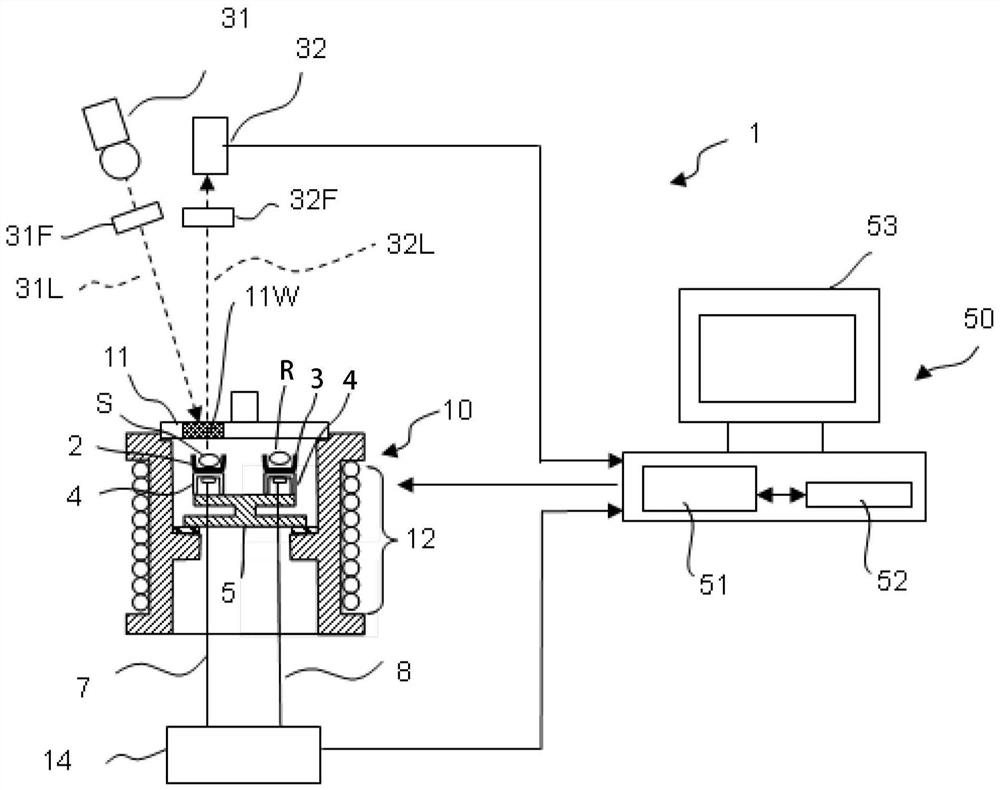

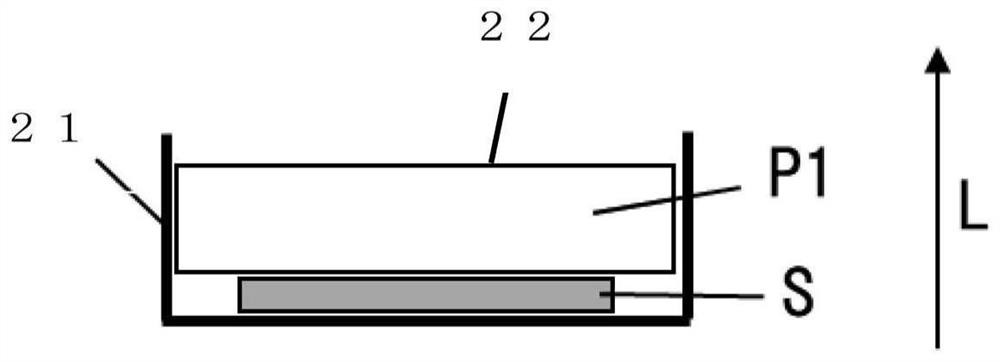

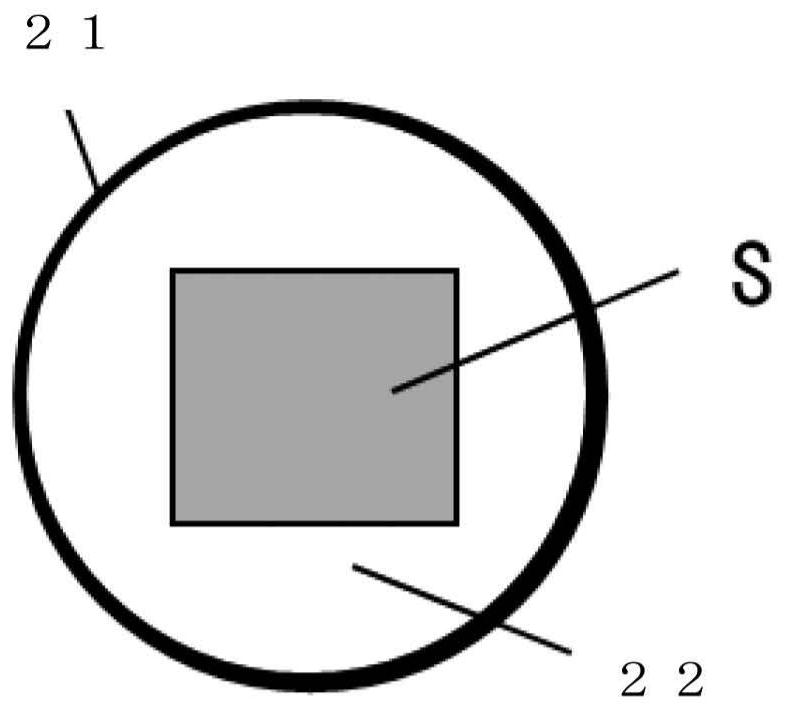

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a sectional view showing the structure of the thermal analysis device according to the embodiment of the present invention.

[0035] The thermal analysis device 1 is a differential scanning calorimeter (DSC), and has the same structure as a conventional differential scanning calorimeter except that a window 11W for observing the inside is provided on the cover 11 of the heating furnace 10. illustrate.

[0036] The thermal analysis device 1 has a measurement sample container 2 for accommodating a measurement sample S, a reference substance container 3 for accommodating a reference substance R, a heating furnace 10, and is connected between the measurement sample container 2 and the reference substance container 3 and the heating furnace 10. A thermal resistor 4 forming a thermal flow path between them, a thermocouple 7 on the measurement sample side, a ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com