Device and method for controlling defects of large disc ring type shell

A technology of control device and disk ring, which is applied in the direction of mold handling equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of large disk ring type shell volume, increased labor intensity of workers, and unhealthy operators, etc., to achieve Save labor costs, facilitate operation, and produce easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

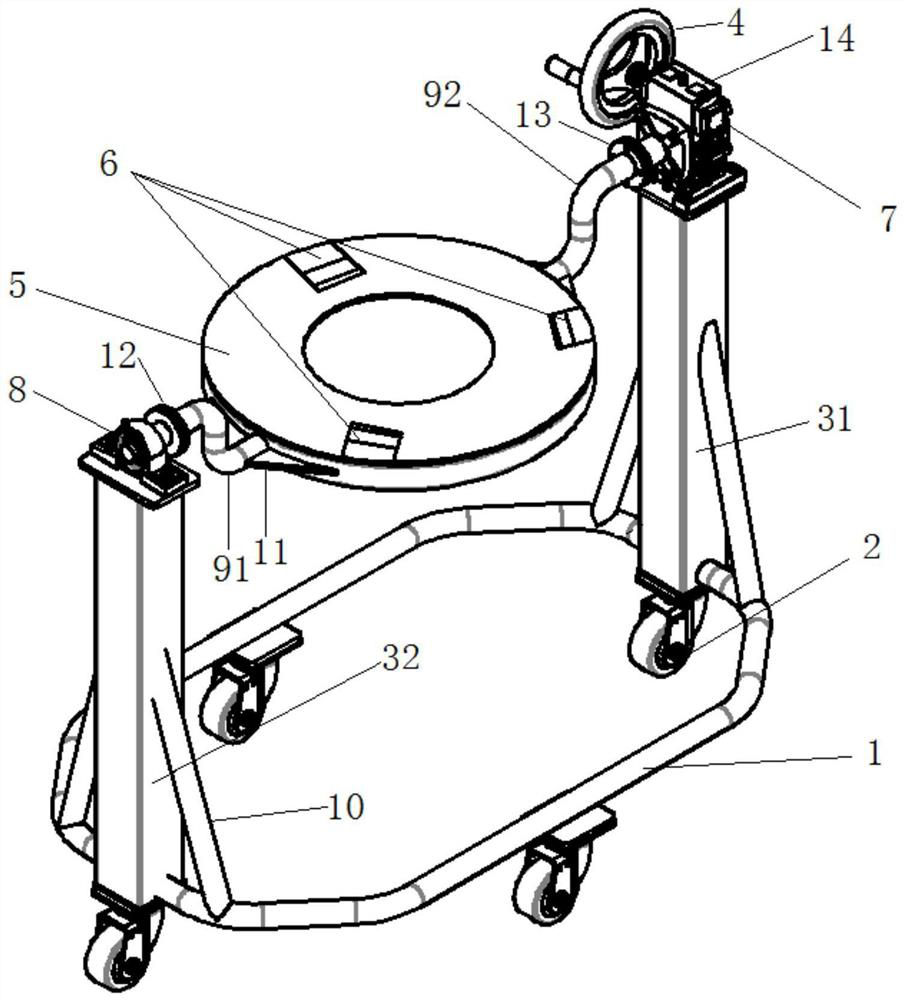

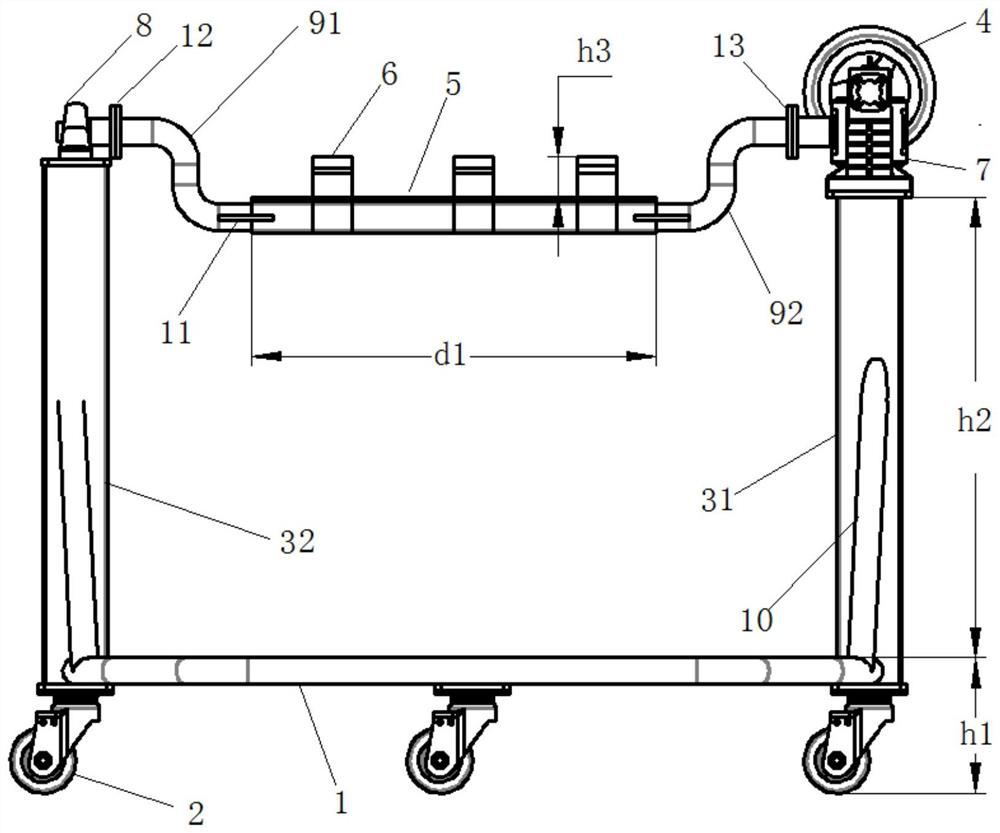

[0057] The outer diameter of the diffuser shell of a certain machine Height h=350mm, ring-shaped, three-pronged sprue, complex gating system structure, shell weight 42kg, number of wax outlets 7, operation requirements placement height H=1100mm, flip angle R=30°, 45°, 180°, in the actual shell inspection and preparation operations, it is very easy to cause handling bumps, and foreign objects fall into the cavity of the shell. Taking the inspection and preparation of 50 shells as an example, it takes an average of 2 to 3 people to operate for 3.5 hours to complete. Using this shell to pour 50 castings, the non-metallic inclusion rate is 10%.

[0058] By adopting the method described in the invention, a mold shell fixing and turning device is manufactured and used for mold shell inspection and mold shell preparation. The total height of the device base connected to the support rod h1+h2=1100mm, the outer diameter of the rotating tray The turning angle r=0°~180° can be realiz...

Embodiment 2

[0060] The outer diameter of the diffuser shell of a certain machine Height h=380mm, ring-shaped, three-pronged sprue, complex gating system structure, mold shell weight 47kg, number of wax discharge ports 8, operation requirements placement height H=1100mm, flip angle R=45°, 180°, In the actual shell inspection and preparation operations, it is very easy to cause handling bumps, and foreign objects fall into the cavity of the shell. Taking the inspection and preparation of 15 shells as an example, it takes an average of at least 2 to 3 people to operate for 3.5 hours to complete. Using this shell to cast 8 castings, the non-metallic inclusion rate is 5%.

[0061] By adopting the method described in the invention, a mold shell fixing and turning device is manufactured and used for mold shell inspection and mold shell preparation. The total height of the device base connected to the support rod h1+h2=1100mm, the outer diameter of the rotating tray It can realize the turning...

Embodiment 3

[0063] The outer diameter of the diffuser shell of a certain machine Height h=380mm, ring-shaped, three-pronged sprue, complex gating system structure, shell weight 50kg, number of wax discharge ports 9, operation requirements placement height H=1100mm, flip angle R=45°, 180°, In the actual shell inspection and preparation operations, it is very easy to cause handling bumps, and foreign objects fall into the cavity of the shell. Taking the inspection and preparation of 10 shells as an example, it takes an average of at least 2 to 3 people to operate for 3.5 hours to complete. Using this shell to pour 10 castings, the non-metallic inclusion rate is 5%.

[0064] By adopting the method described in the invention, a mold shell fixing and turning device is manufactured and used for mold shell inspection and mold shell preparation. The total height of the device base connected to the support rod h1+h2=1100mm, the outer diameter of the rotating tray It can realize the turning ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com