Surface arc weld seam polishing device for steel container

A steel container and polishing device technology, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, and devices for fixing grinding wheels, etc., can solve problems such as low work efficiency and increased labor intensity of staff, and reduce labor costs. Strength, improved polishing accuracy, and stable transmission connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

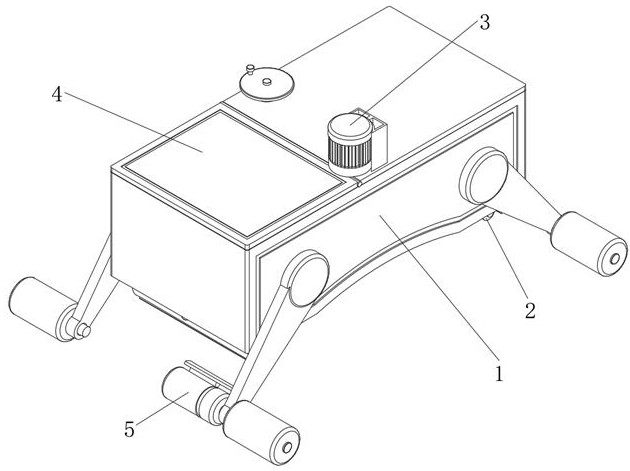

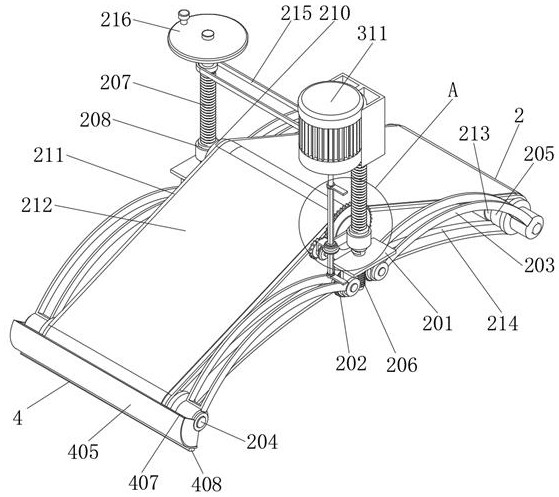

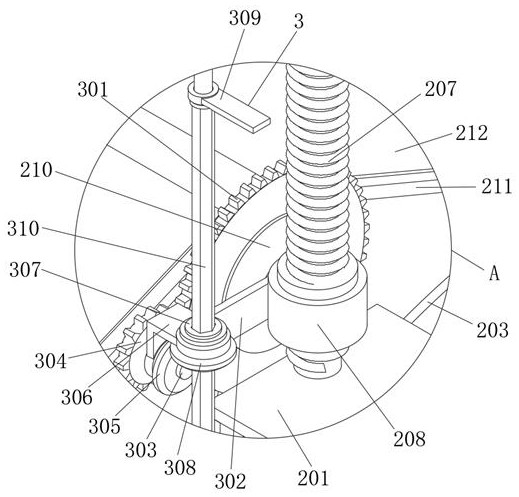

[0045] see Figure 1-3 with Figure 5-7 as well as Figure 10 , a steel container surface arc weld polishing device, including a casing 1, an adjustable polishing part 2 is installed inside the casing 1, and the adjustable polishing part 2 includes two connecting frames 201 symmetrically arranged inside the casing 1 The bottom of each connecting frame 201 is connected with a worm wheel 202 for symmetrical rotation, and the outer sides of the two worm wheels 202 are fixedly connected with a swing arm 203, and the outer ends of the two corresponding front and rear swing arms 203 are fixedly connected with a fixed shaft 204 , and the outer movable sleeve of the fixed shaft 204 is provided with a roller column 1 205, and a worm 206 is meshed and connected between the two symmetrical worm wheels 202, and the worm 206 is rotatably connected to the middle position of the corresponding connecting frame 201, and the top of the worm 206 is fixed The screw rod 207 is welded, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com