Organic silicon foaming sheet for electronic product and preparation method thereof

A technology of foamed sheet and silicone, which is applied in the field of silicone foamed sheet for electronic products and its preparation, can solve problems such as the inability to prepare ultra-thin foamed sheet, and achieve excellent waterproof, shock-absorbing and sealing properties, Effects of excellent shock absorption performance, excellent flame retardancy and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

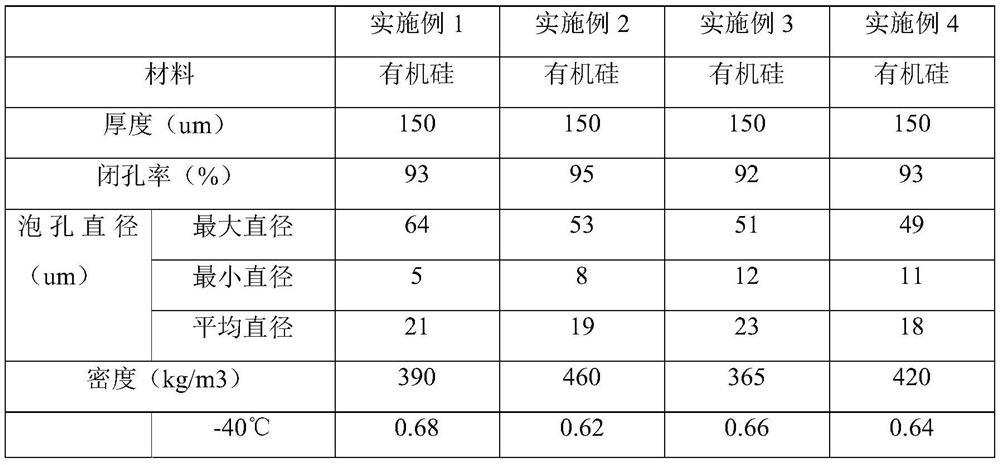

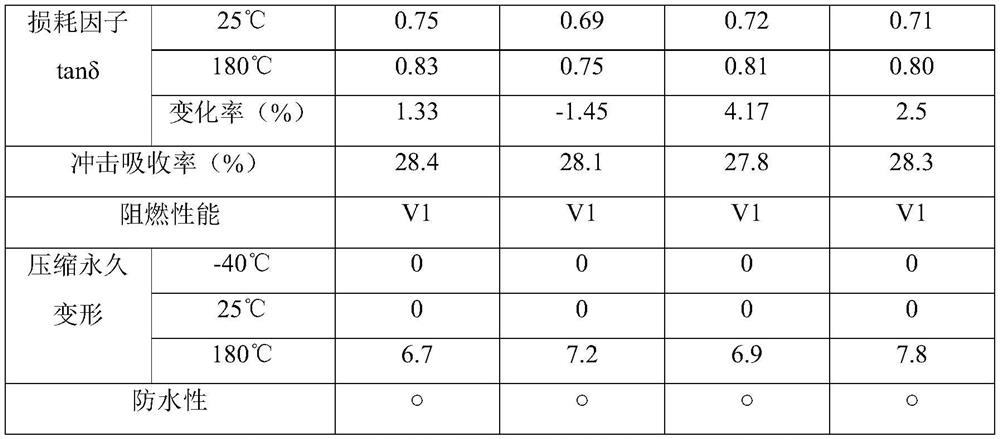

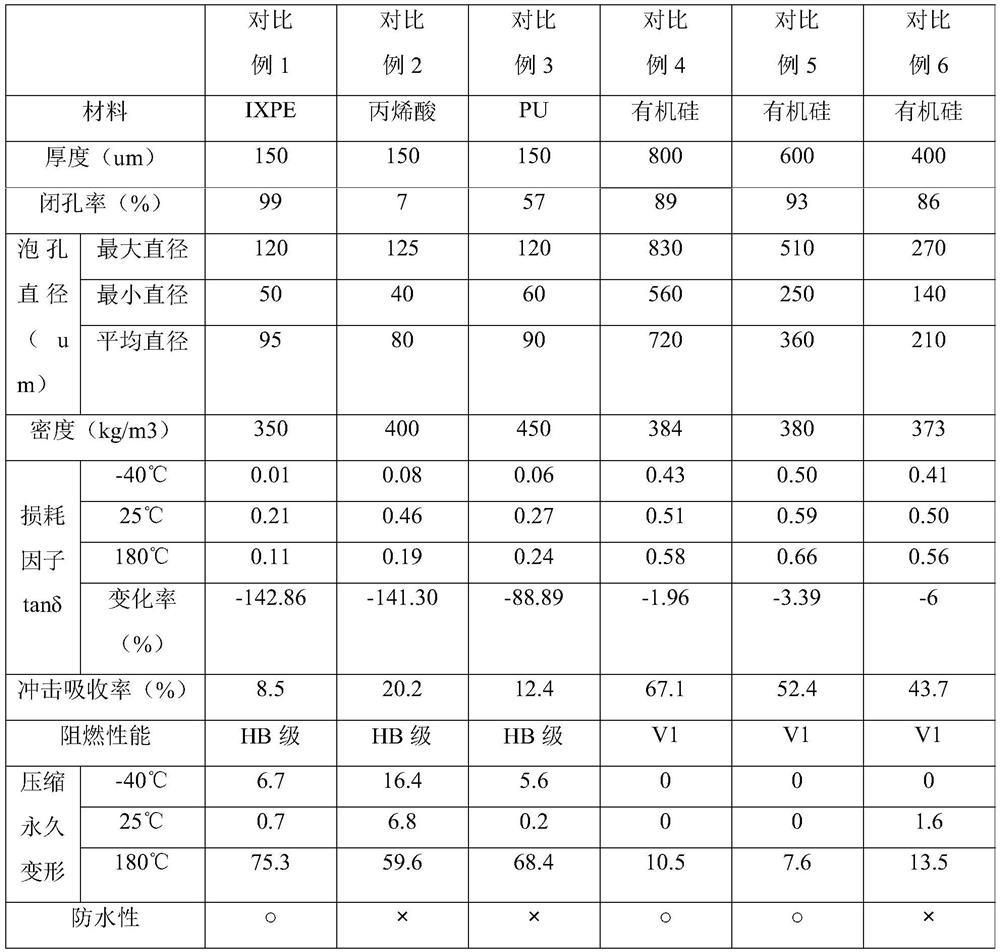

Examples

preparation example Construction

[0041] In some embodiments of the present invention, a method for preparing the silicone foam sheet is also provided, comprising the following steps:

[0042] (1) Mix the entire amount of the component (B), component (D), and component (H) with half of the amount of the component (A) with a non-interventional homogenizer to obtain the first combination Object A;

[0043] (2) The other half of the amount of component (C), component (E), component (F), component (G), component (I) and the other half of the amount of component (A) is not The intervening homogenizer is mixed to obtain the second composition B;

[0044] (3) Keep the first composition A and the second composition B at a constant temperature in a planetary mixer (heat is generated during the stirring process, cool with a mold temperature machine, and maintain the temperature at 30°C to 40°C), and stir under reduced pressure for 5 minutes to obtain silicone resin composition.

[0045] The present invention prepares...

Embodiment 1

[0052] 50 parts by mass of vinyl molar ratio (the ratio of the amount of vinyl to the amount of siloxane chain link) is 0.16% vinyl-terminated polysiloxane, 10 parts by mass of vinyl molar ratio is 5% Polyvinyl polysiloxane, 5 parts by mass The specific surface area of surface treatment with hexamethyldisilazane is 160m 2 Fumed white carbon black (R8200, commercially available product) and 1 mass part of castor catalyst (platinum metal content: about 5000ppm) in / g were mixed with a non-interventional homogenizer for 8min to obtain component A;

[0053] 50 parts by mass of vinyl molar ratio (the ratio of the amount of vinyl to the amount of siloxane chain link) is 0.16% vinyl-terminated polysiloxane, 3.30 parts by mass of silicon hydrogen group content is 1.6wt% The side chain of polysiloxane containing silylhydrogen group (make the number of moles of hydrogen atoms bonded to silicon atoms in the polysiloxane of side chain containing silylhydrogen group relative to the termi...

Embodiment 2

[0056] 50 parts by mass of vinyl molar ratio (ratio of the amount of vinyl material to the amount of material of siloxane chain link) is 0.32% vinyl-terminated polysiloxane, 3 parts by mass vinyl molar ratio is 22% Polyvinyl polysiloxane, 5 parts by mass, surface-treated with hexamethylenedisilazane, has a specific surface area of 300m 2 / g of fumed white carbon black, 1 mass part of castor catalyst (platinum metal content: about 5000ppm) was mixed with a non-intervention homogenizer for 8min to obtain component A;

[0057] 50 parts by mass of vinyl molar ratio (the ratio of the amount of vinyl to the amount of siloxane chain link) is 0.32% vinyl-terminated polysiloxane, 4.72 parts by mass of silicon hydrogen group content is 1.6wt% The side chain of polysiloxane containing silylhydrogen group (make the number of moles of hydrogen atoms bonded to silicon atoms in the polysiloxane of side chain containing silylhydrogen group relative to the terminal vinyl polysiloxane and pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com