Hot-fragrance explosive candle essence and preparation method thereof

A technology for candles and essences, applied in the field of flavors and fragrances, which can solve the problems of reduced aroma explosive power, difficulty in maintaining long-lasting aroma, and reduced aroma intensity, and achieve the effect of long-lasting aroma burst, strong persistence, and good aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

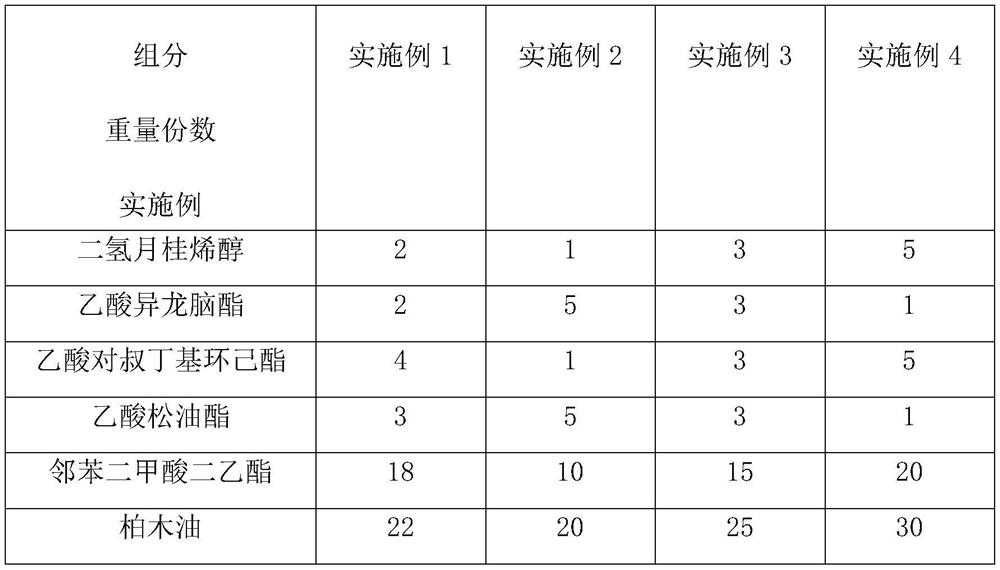

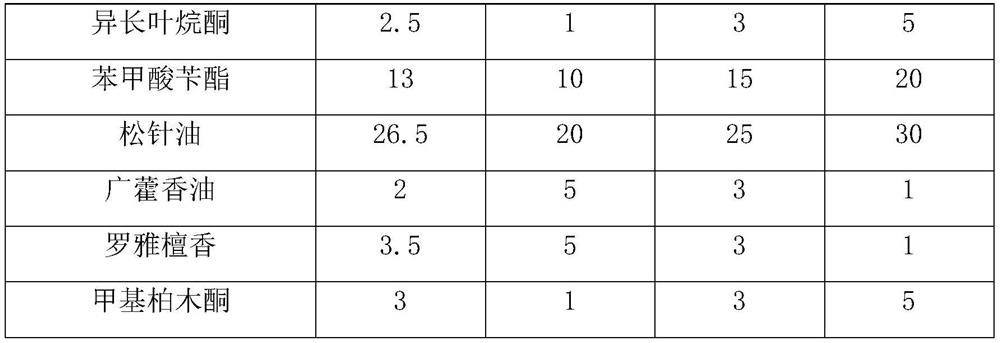

Image

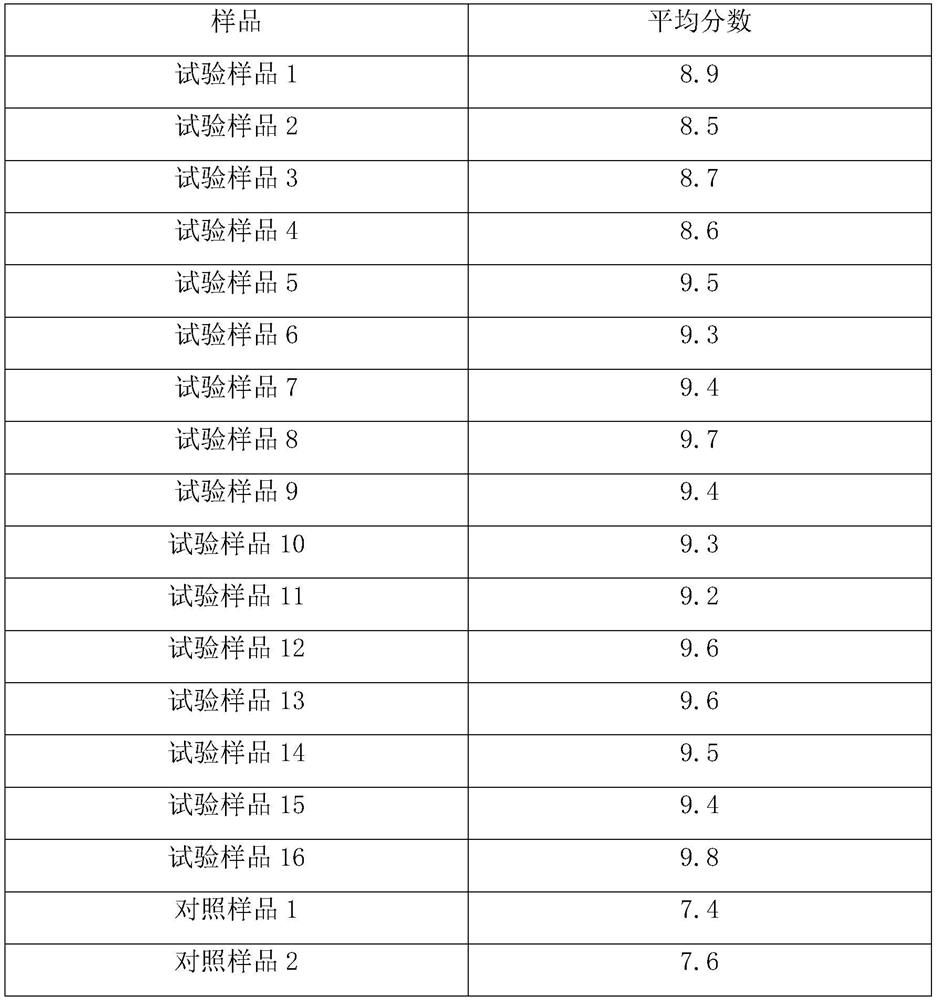

Examples

preparation example 1

[0047] S1. Prepare the raw materials of hawthorn tincture, honey and tamarind extract according to the ratio, and the mass ratio between them is 1:0.55:1.3;

[0048] S2. Dissolve the raw materials in step S1 in pure water, reach saturation and mix evenly, then heat in a water bath, the temperature of the water bath is 50°C, concentrate after distillation and extraction, the extraction time of distillation is 3h, the extract is dichloromethane, and the rotation is selected. Concentrate to one-fifth of the original volume with an evaporator to obtain a mixed extract.

preparation example 2

[0050] S1. Prepare the raw materials of hawthorn tincture, honey and tamarind extract according to the ratio, and the mass ratio between them is 1:0.4:1.1;

[0051] S2. Dissolve the raw materials in step S1 in pure water, reach saturation and mix evenly, then heat in a water bath, the temperature of the water bath is 50°C, concentrate after distillation and extraction, the extraction time of distillation is 3h, the extract is dichloromethane, and the rotation is selected. Concentrate to one-fifth of the original volume with an evaporator to obtain a mixed extract.

preparation example 3

[0053] S1. Prepare the raw materials of hawthorn tincture, honey and tamarind extract according to the ratio, and the mass ratio between them is 1:0.7:1.5;

[0054] S2. Dissolve the raw materials in step S1 in pure water, reach saturation and mix evenly, then heat in a water bath, the temperature of the water bath is 50°C, concentrate after distillation and extraction, the extraction time of distillation is 3h, the extract is dichloromethane, and the rotation is selected. Concentrate to one-fifth of the original volume with an evaporator to obtain a mixed extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com