A kind of preparation method of cnts/al-li high-strength composite material

A high-strength composite material and composite material technology, applied in the field of composite material preparation, can solve the problems of poor strength and elongation of aluminum-lithium alloy, and achieve the effect of improving the weight reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

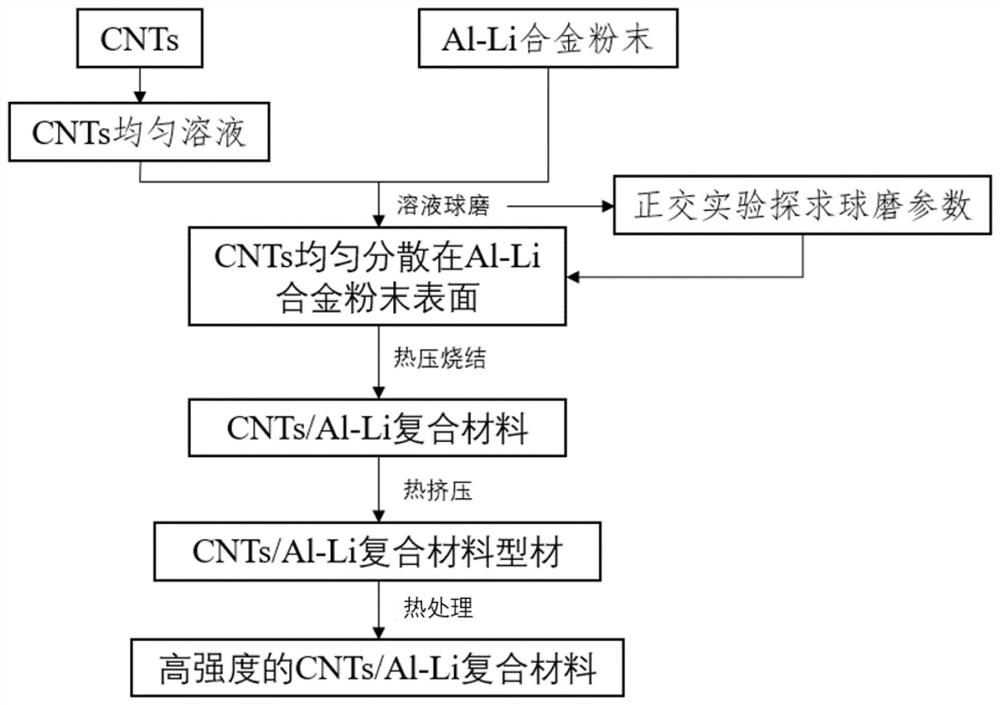

[0034] The invention provides a preparation method of CNTs / Al-Li high-strength composite material, comprising the following steps:

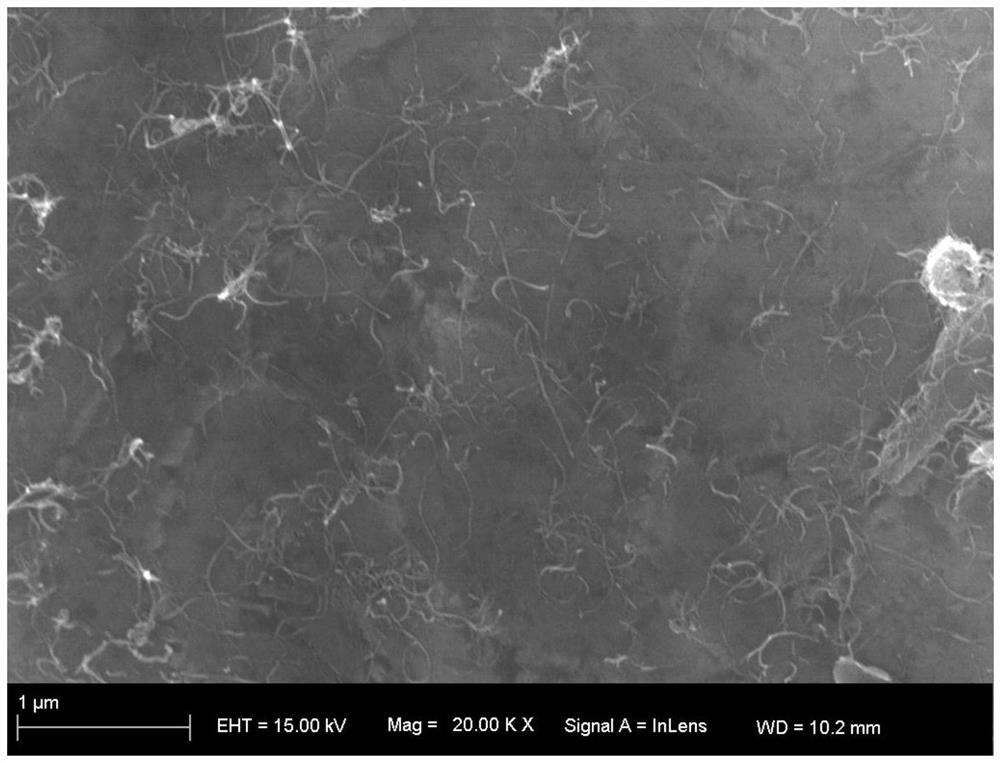

[0035] Step 1. Prepare a homogeneous CNTs solution

[0036]Weigh 60g of 2195 alloy powder, the particle size of the alloy powder is 325 mesh (45 m), weigh 300g of grinding balls, 240g of large balls, and 60g of small balls, that is, the ratio of balls to materials is 5:1, and the ratio of large and small balls is 4:1. Add 60g of isopropanol solution in a clean beaker, weigh 0.3g of the zwitterionic dispersant (dodecyldimethylaminobetaine), join in the isopropanol solution, stir with a magnetic stirrer for 10min, let After the dispersant is fully dissolved, weigh the CNTs with a mass fraction of 0.3g. The CNTs are multi-walled CNTs with a diameter of about 30-50nm. Add the CNTs to the dispersed solution, and seal the mouth of the beaker with plastic wrap to prevent the solution from Volatilize, then put the solution into an ultrasonic machine, an...

Embodiment 2

[0047] The present invention provides a kind of preparation method of CNTs / Al-Li high-strength composite material, such as figure 1 shown, including the following steps:

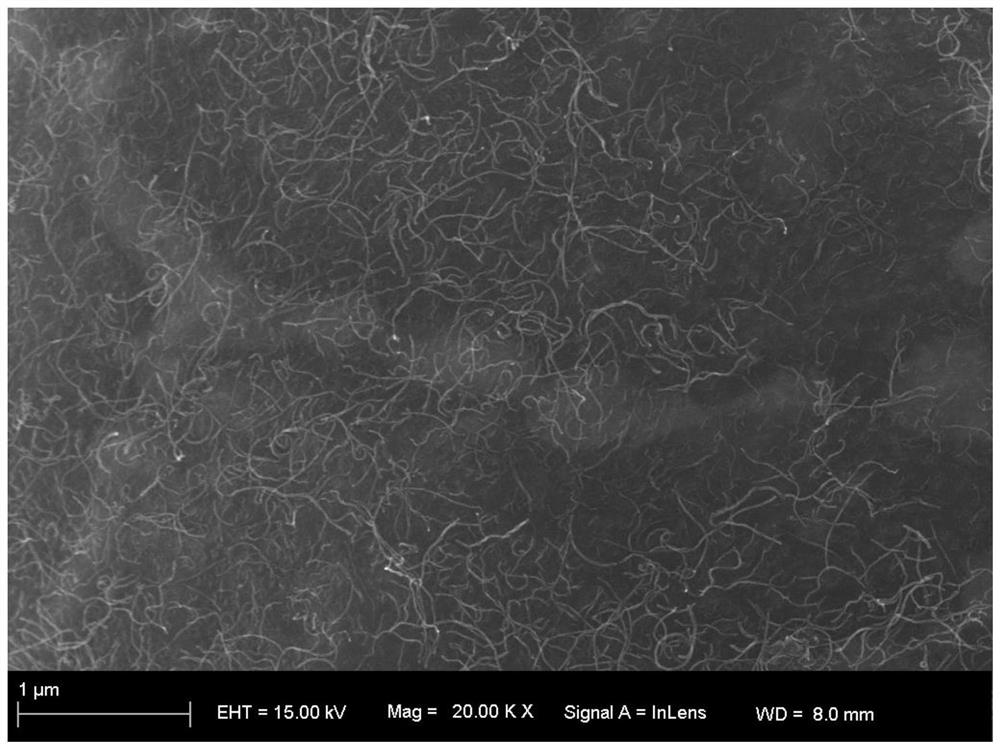

[0048] Step 1. Prepare a homogeneous CNTs solution

[0049] Weigh 60g of 2195 alloy powder, the particle size of the alloy powder is 325 mesh (45 m), weigh 300g of grinding balls, 240g of large balls, and 60g of small balls, that is, the ratio of balls to materials is 5:1, and the ratio of large and small balls is 4:1. Add 60g of isopropanol solution in a clean beaker, weigh 0.6g of the zwitterionic dispersant (dodecyldimethylaminobetaine), join in the isopropanol solution, stir with a magnetic stirrer for 10min, let After the dispersant is fully dissolved, weigh the CNTs with a mass fraction of 0.6g. The CNTs are multi-walled CNTs with a diameter of about 30-50nm. Add the CNTs to the dispersed solution, and seal the mouth of the beaker with plastic wrap to prevent the solution from Volatilize, then put th...

Embodiment 3

[0060] The invention provides a preparation method of CNTs / Al-Li high-strength composite material, comprising the following steps:

[0061] Step 1. Prepare a homogeneous CNTs solution

[0062]Weigh 60g of 2195 alloy powder, the particle size of the alloy powder is 325 mesh (45 m), weigh 300g of grinding balls, 240g of large balls, and 60g of small balls, that is, the ratio of balls to materials is 5:1, and the ratio of large and small balls is 4:1. Add 60g of isopropanol solution in a clean beaker, weigh 0.9g of the zwitterionic dispersant (dodecyldimethylaminobetaine), join in the isopropanol solution, stir with a magnetic stirrer for 10min, let After the dispersant is fully dissolved, weigh the CNTs with a mass fraction of 0.9g. The CNTs are multi-walled CNTs with a diameter of about 30-50nm. Add the CNTs to the dispersed solution, and seal the mouth of the beaker with plastic wrap to prevent the solution from Volatilize, then put the solution into an ultrasonic machine, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com