Light occlusion type under-wall strip-shaped foundation and construction method thereof

A strip-shaped basic and integrated technology, applied in basic structure engineering, construction and other directions, can solve the problems of financial consumption, material consumption, power consumption and environmental protection that cannot meet modern buildings, etc., and achieve the effect of improving labor productivity, saving construction period and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

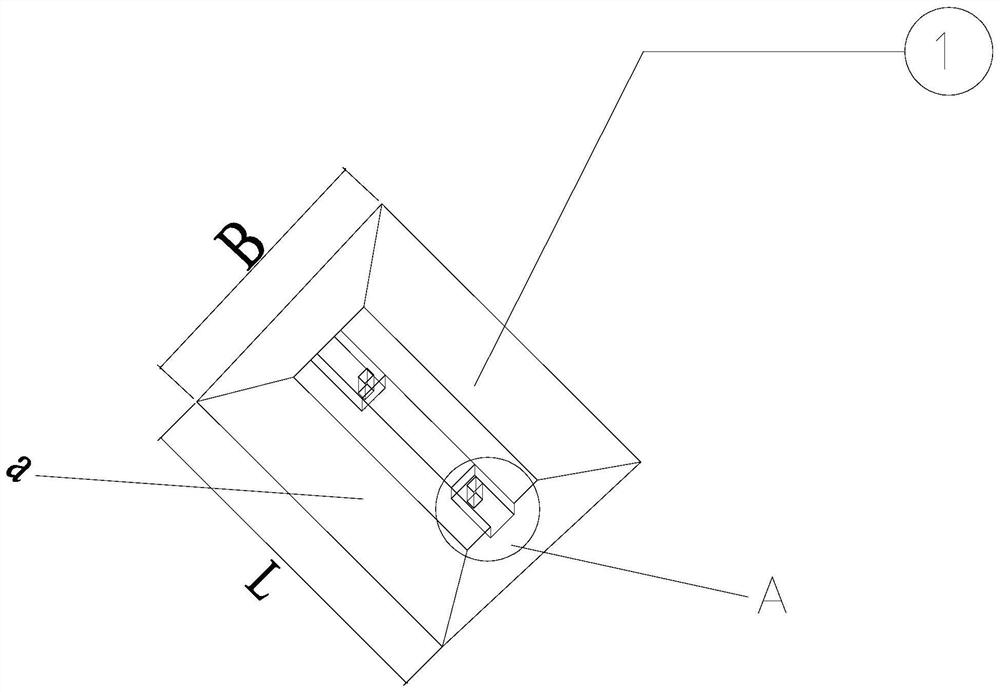

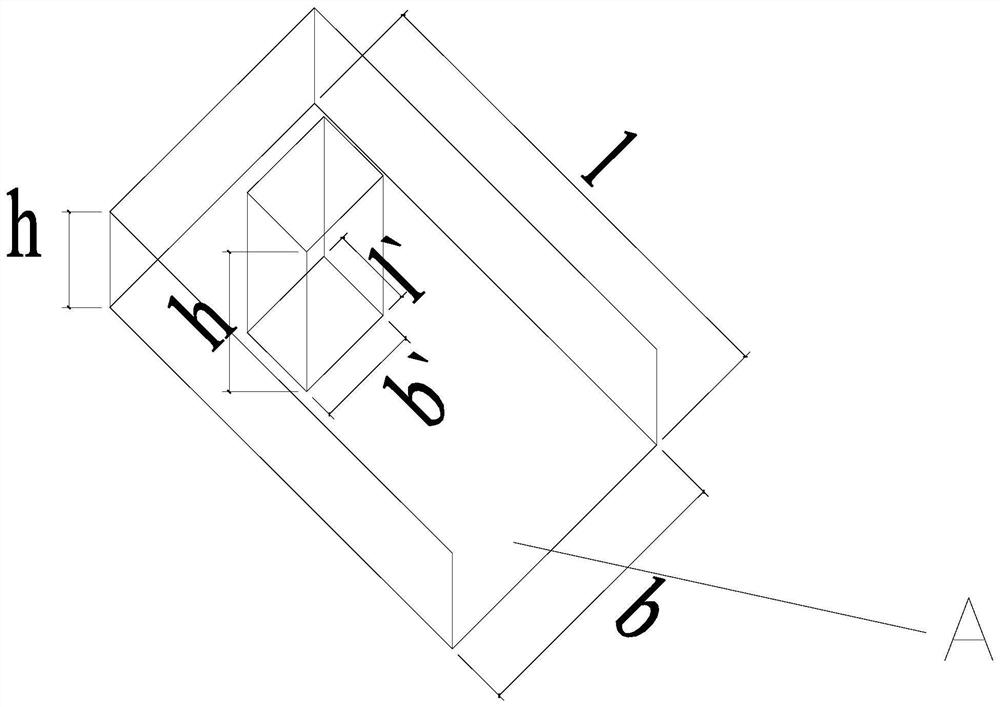

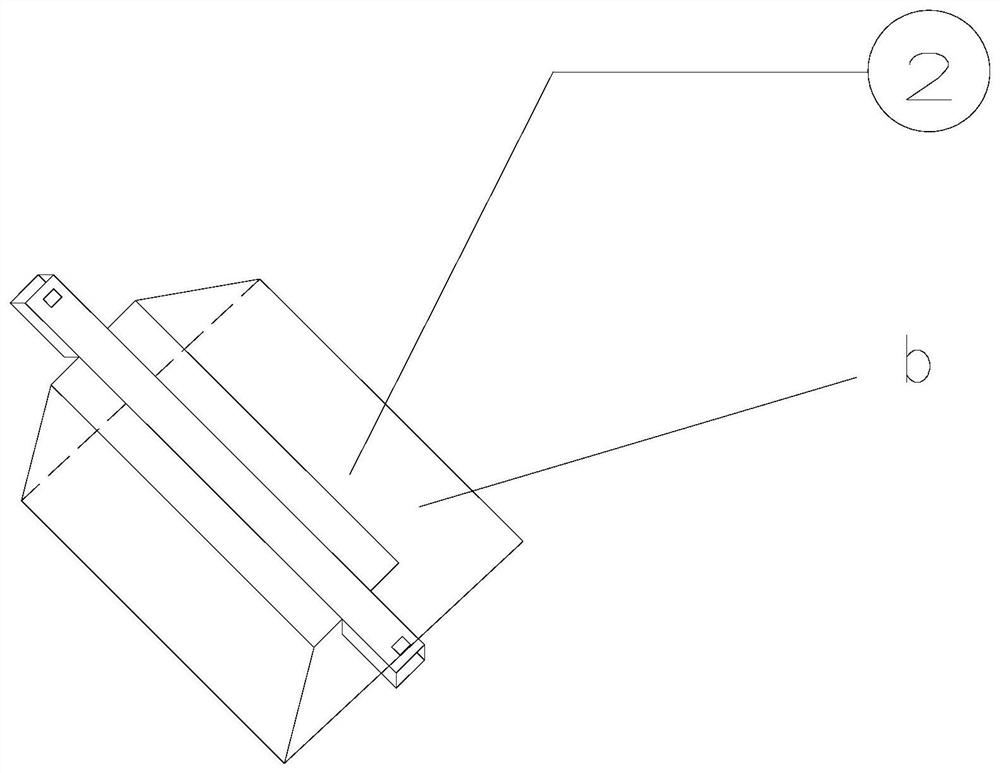

[0034] Embodiment 1, with reference to Image 6 As shown, in this embodiment, two mortise-type standard strip foundations 2 are interlocked and riveted to form a whole through mortise holes 7 and tenons 6 on one tenon-type standard strip foundation 1, wherein the tenon-type standard strip The longitudinal dimension L of the bottom surface of the shaped foundation 1 is smaller than the transverse dimension B, and a depression with a vertical length of l, a horizontal length of b, and a downward depth of h is left at the center of the two ends of the top surface of the foundation. A protruding tenon 6 with the tenon facing up, the bottom surface is connected to the bottom surface of the depression, the height of the tenon is h, the top surface is level with the top surface of other areas of the foundation, the transverse dimension of the tenon 6 is b', which is half of b, and the longitudinal length is l' It is half of l, and the tenon head 6 is located at the center of the bott...

Embodiment 2

[0035] Embodiment 2, with reference to Figure 7 As shown, the top surface of the bar-shaped foundation cross joint 3 in this embodiment is arranged with a tenon 6 at each of the four cross-shaped ends. The tenon holes 7 on the 2 are interlocked and riveted to form a whole.

Embodiment 3

[0036] Embodiment 3, with reference to Figure 8 As shown, the bar-shaped foundation right-angle joint 4 of this embodiment is provided with a tenon 6 on the two sides adjacent to the top surface, and the bar-shaped foundation right-angle joint 4 is connected with two mortise-type standard bar-shaped joints by two tenons 6. The tenon holes 7 of the foundation 2 are interlocked and riveted to form a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com