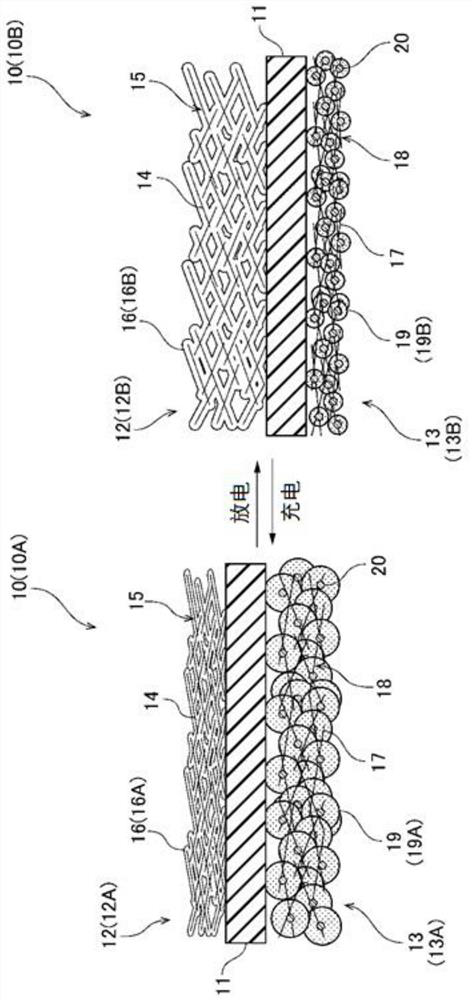

Secondary battery negative electrode, secondary battery, and manufacturing method of secondary battery negative electrode

A secondary battery and negative electrode technology, which is applied in the direction of secondary batteries, battery electrodes, electrode carriers/collectors, etc., can solve the problem of short circuit between the positive electrode and the negative electrode, and achieve the improvement of mass capacity density, volume capacity density, mass capacity density and High volume capacity density, effect of increasing volume capacity density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

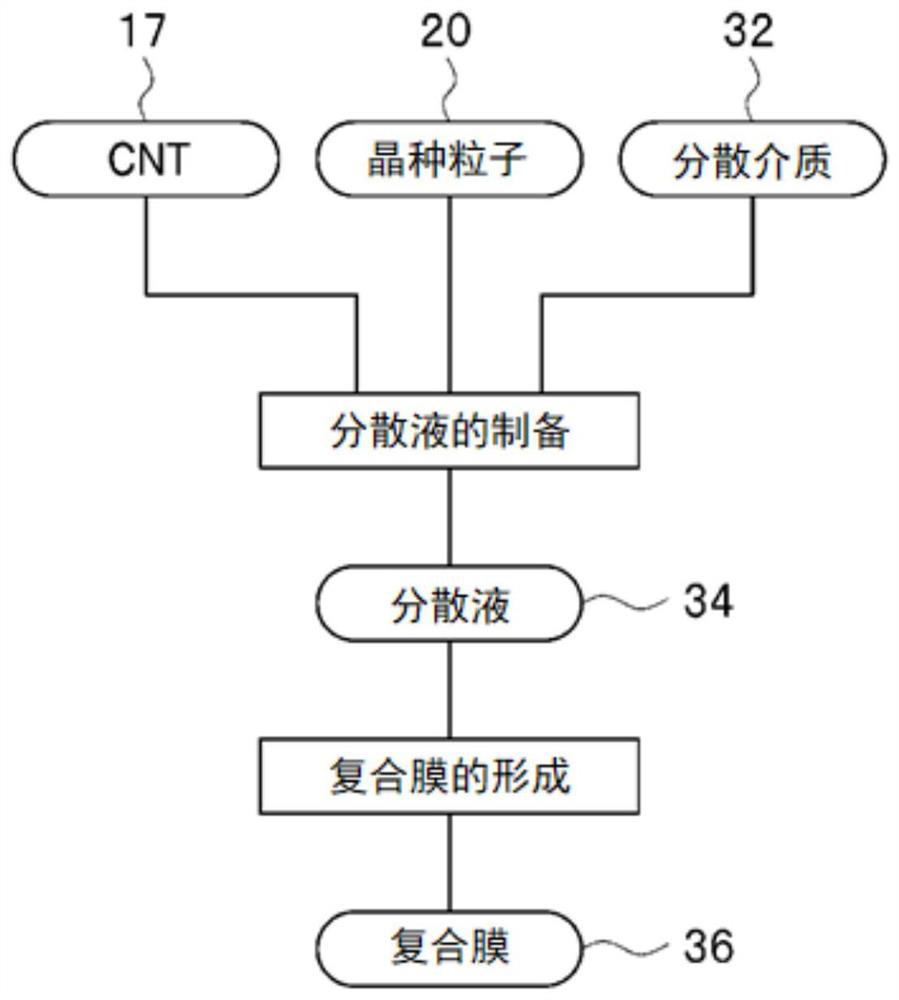

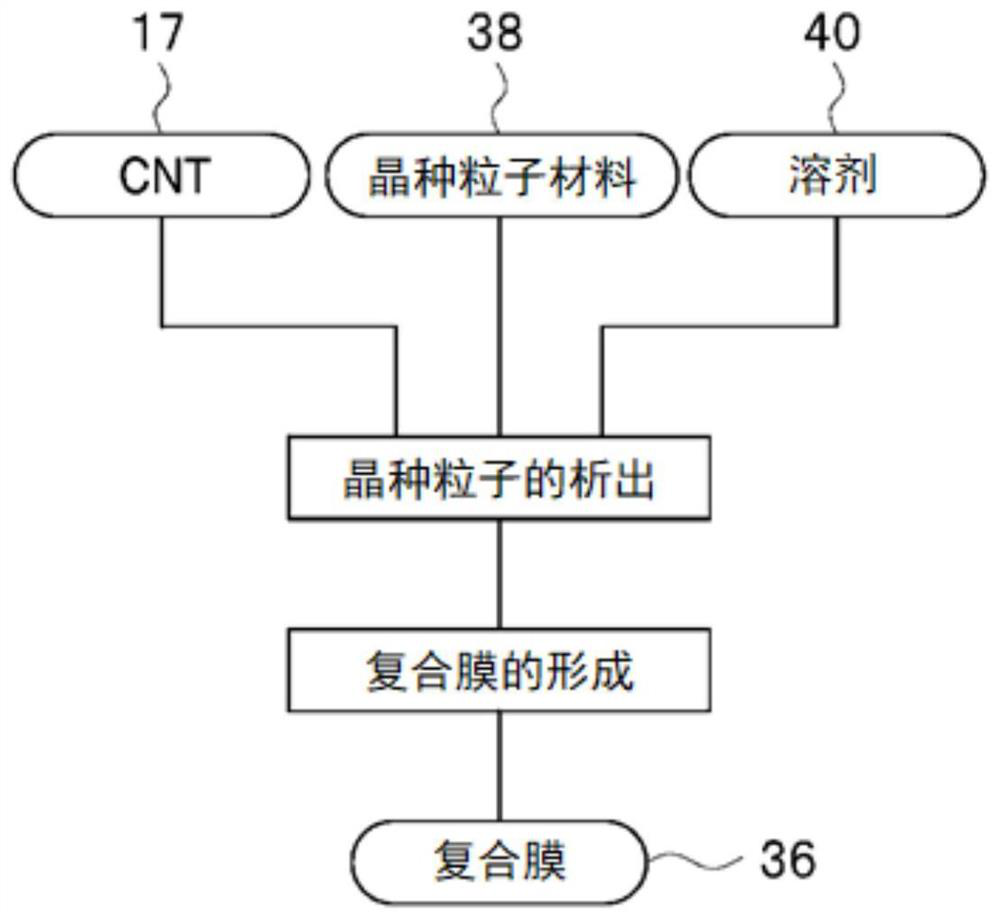

Method used

Image

Examples

Embodiment 13

[0113] The result of the cycle test of the test cell of embodiment 13 is as follows Figure 15 shown. The cycle test result of the test battery of comparative example 1 is as follows Figure 16 shown. The cycle test result of the test battery of comparative example 2 is as follows Figure 17 shown. Figures 15-17 In , the vertical axis represents voltage, and the horizontal axis represents time.

[0114] In the test battery of Example 13, by Figure 15 It can be confirmed that 94 cycles of operation can be performed. Since there are two electrodes, among them, the mass of Li foil monolithic (2.67mg / cm 2 ) and the mass of the two composite films that constitute the first electrode and the second electrode (in each composite film, the mass of Cu is 0.12mg / cm 2 , the mass of CNT is 0.28mg / cm 2 ) has a total mass of 3.47mg / cm 2 , and the design capacity of the electrode is 4mAh / cm 2 , so the mass basis capacity density of each monolithic electrode is 2305mAh / g. The test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com