Geological mineral mining, sorting and sampling device based on machine learning

A machine learning, sampling device technology, applied in solid separation, grain processing, chemical instruments and methods, etc., can solve problems such as filter clogging, influence, processing step influence, etc., to avoid clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

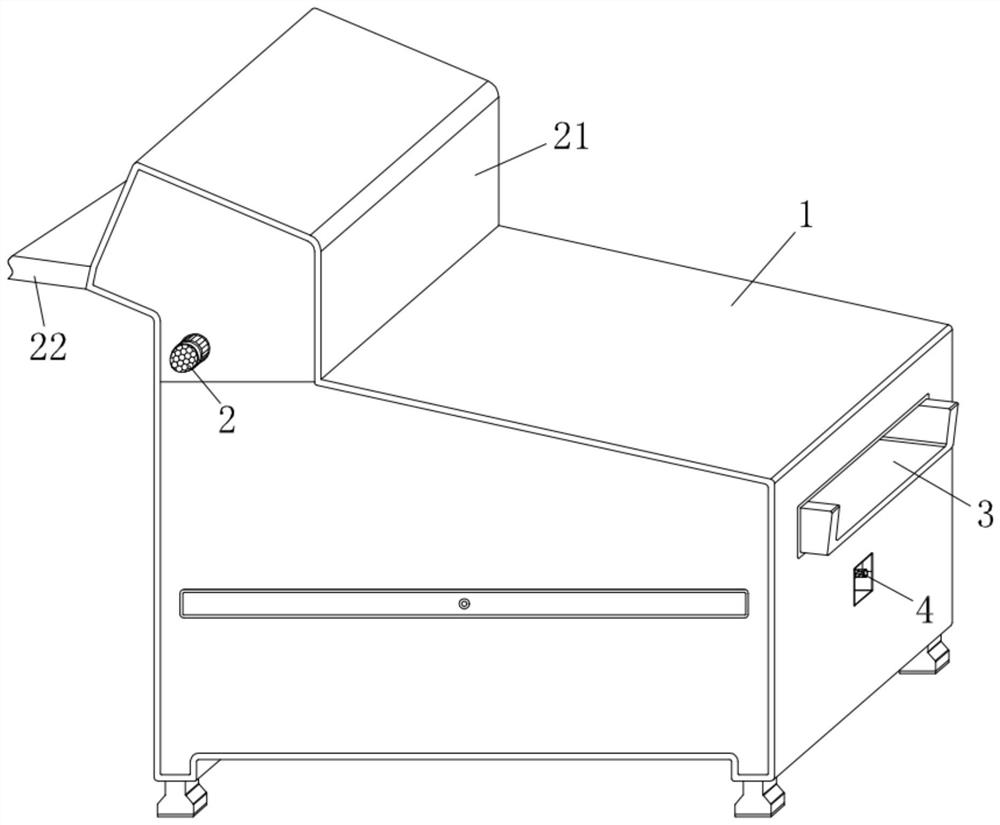

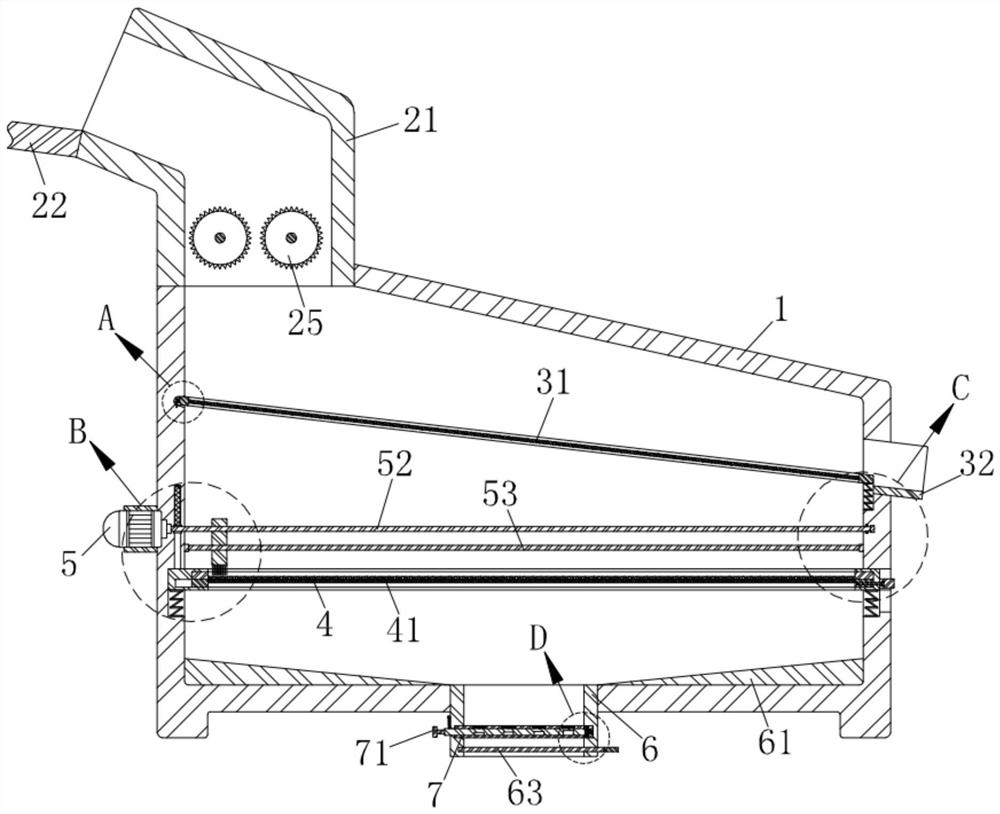

[0028] Such as Figure 1-Figure 8 As shown, a kind of machine learning-based geological mineral mining sorting and sampling device according to the present invention includes a housing 1, a feeding mechanism 2 is provided on the housing 1, and a preliminary screening mechanism is provided in the housing 1 3 and a filter mechanism 4, the casing 1 and the filter mechanism 4 are provided with a dredging mechanism 5, the casing 1 is provided with a discharge mechanism 6, and the discharge mechanism 6 is provided with a sampling mechanism 7.

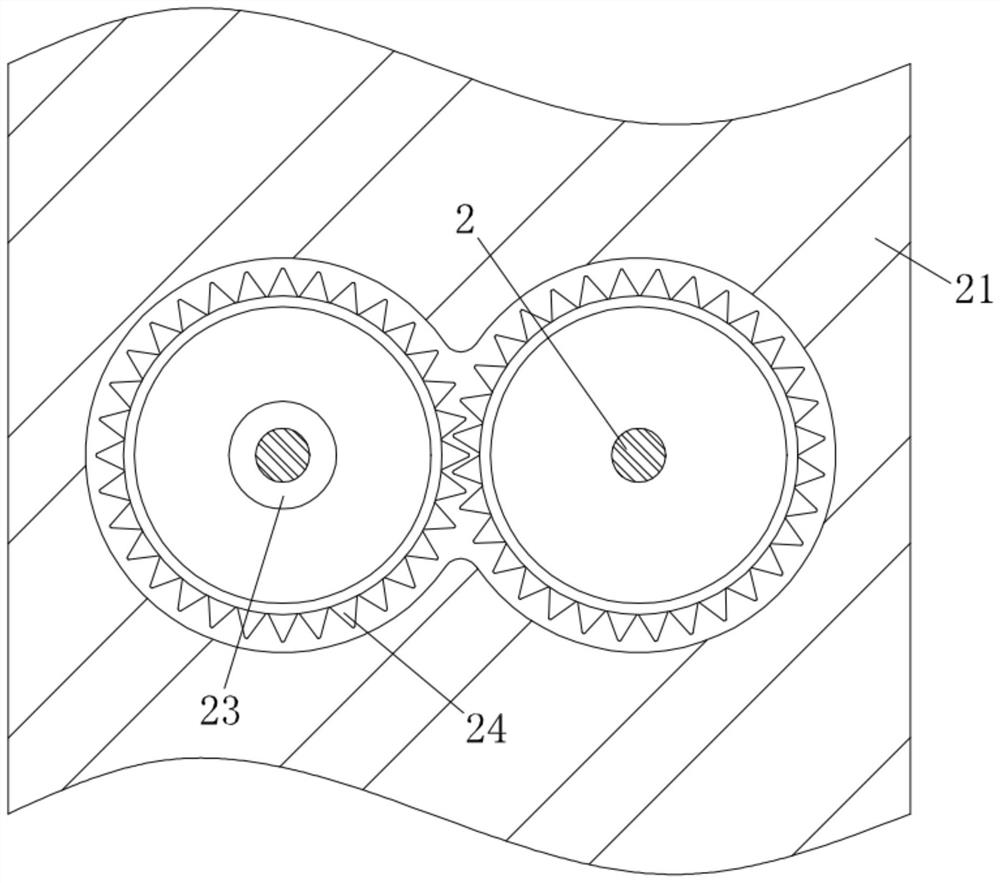

[0029]Specifically, the feeding mechanism 2 includes a feeding frame 21, the housing 1 is fixedly connected with the feeding frame 21, the whole of the feeding frame 21 is in the shape of a bent rectangular frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com