3D printing concrete prepared from recycled aggregate and preparation method of 3D printing concrete

A recycled aggregate and 3D printing technology, applied in the direction of additive processing, can solve problems affecting concrete strength, high heat of hydration, high temperature stress, etc., to improve cohesion and water retention, increase compactness, and avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

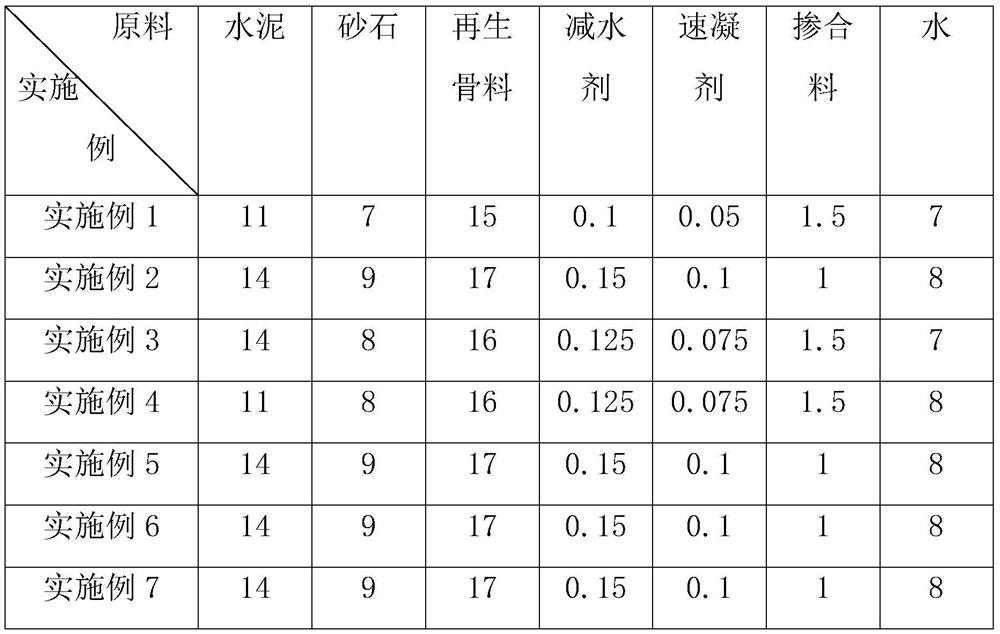

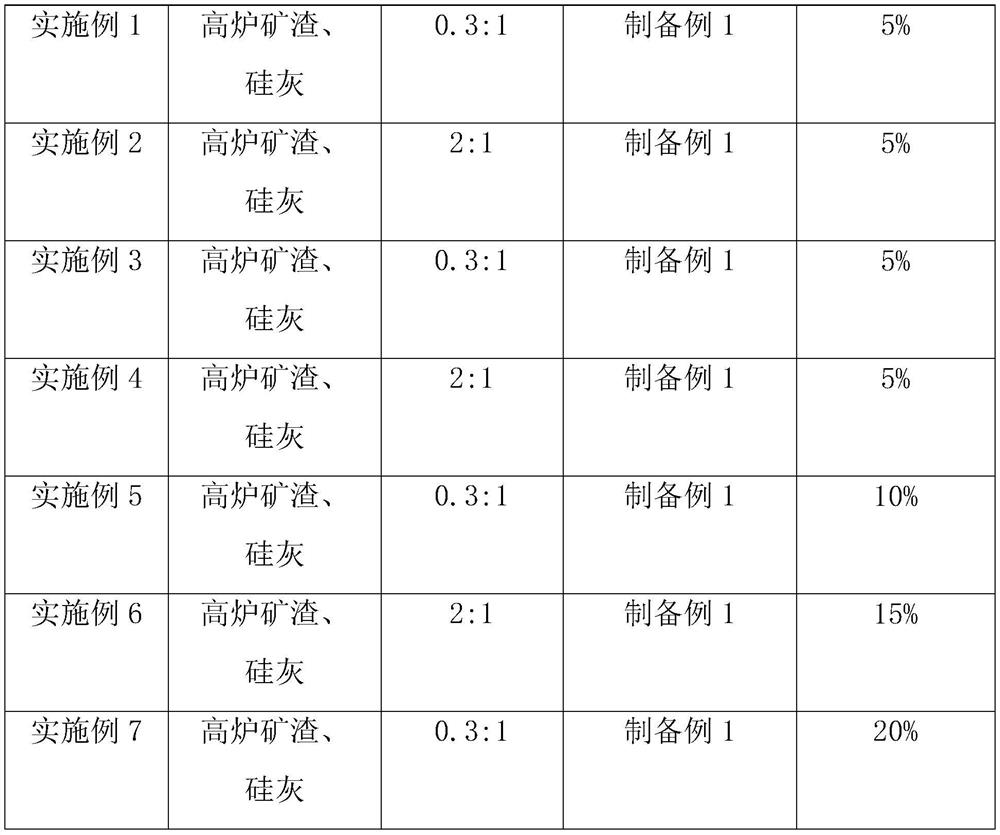

Examples

preparation example 1

[0041] Use gamma rays to irradiate a mixture of 0.025kg of poly-N-isopropylacrylamide and 0.025kg of vinylidene fluoride for 3 minutes, so that poly-N-isopropylacrylamide is grafted onto vinylidene fluoride to make a temperature-sensitive membrane. preparation.

preparation example 2

[0043]The mixture of 0.025 kg of poly-N-isopropylacrylamide and 0.025 kg of polyethylene terephthalate was irradiated with gamma rays for 3 minutes to graft poly-N-isopropylacrylamide onto polyethylene terephthalate Temperature sensitive membrane preforms were made on diesters.

preparation example 3

[0045] A mixture of 0.025 kg poly-N-isopropylacrylamide and 0.025 kg polypropylene was irradiated with gamma rays for 3 minutes to graft poly-N-isopropylacrylamide onto polypropylene to prepare a temperature-sensitive membrane preform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap