Anchor cable anchoring multi-stage synergistic stirring and lifting guide assembly and working method thereof

An anchoring cable and anchoring technology, which is applied in the field of anchoring cable anchoring multi-stage synergistic stirring guide components, can solve the problem of reducing the effective anchoring length, etc., and achieve the goal of increasing the effective anchoring length, ensuring the safety of personnel and equipment, and enhancing the shear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

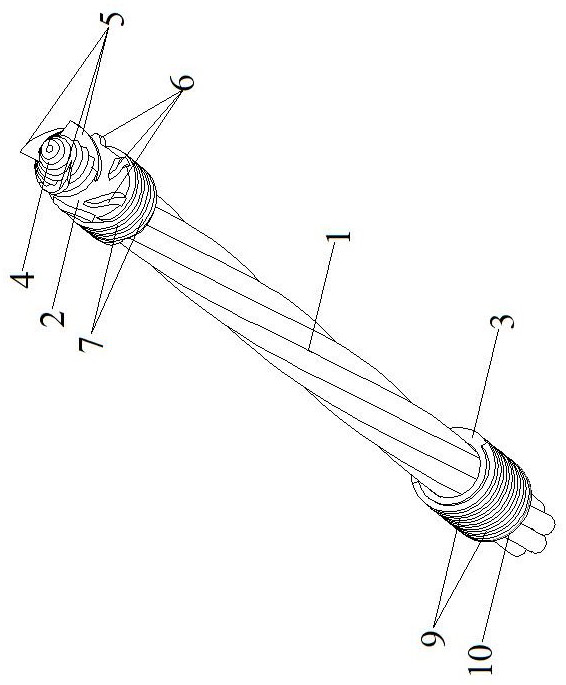

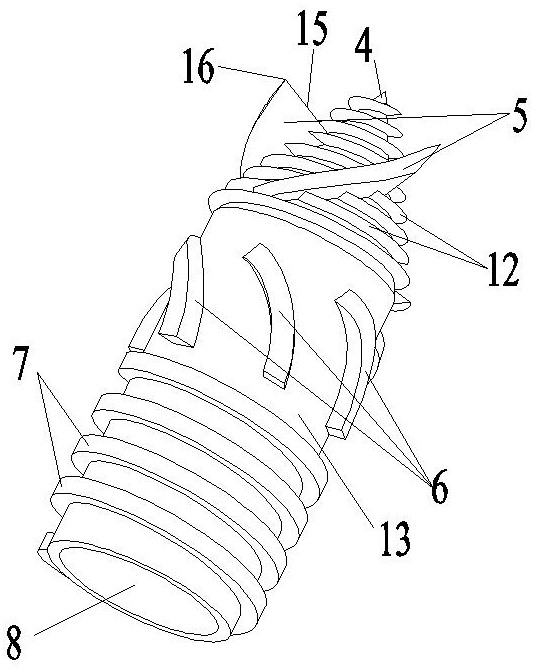

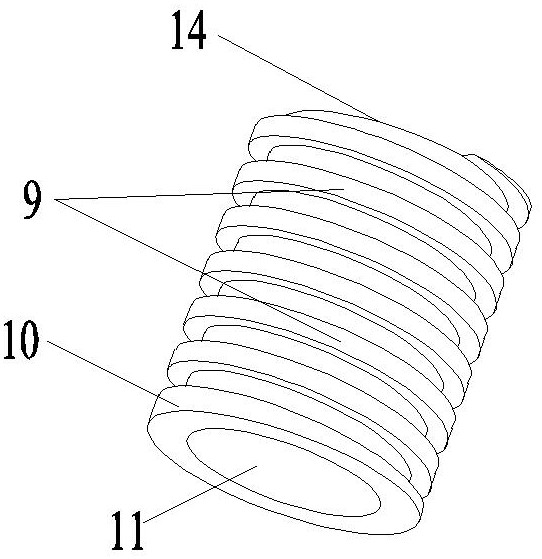

[0033] Such as Figure 1-Figure 3 As shown, an anchor cable anchoring multi-stage synergistic stirring guide assembly of the present invention includes a stirring and crushing member 2 installed and fixed on the upper end of the anchor cable 1 and a blocking and lifting guide member 3 set in the middle and upper part of the anchor cable 1;

[0034] The stirring and crushing member 2 includes an upper conical drill bit 4 and a lower cylindrical body 13 with an integrated structure. The inner hole of the cylindrical body 13 is an anchor cable installation cavity 8 with an open lower end, and the upper end of the anchor cable 1 is inserted and fixed on the anchor cable. Inside the installation cavity 8, the conical drill bit 4 is a conical structure with a thin top and a thick bottom. The outer circle of the conical drill bit 4 is provided with a crushing stirring paddle 5, and the outer circle of the cylindrical body 13 is sequentially provided with polymerization stirring blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com