A scanning tunneling microscope needle tip processing device

A technology of scanning tunnels and processing devices, applied in the field of microscopy, can solve problems such as large randomness, organic pollution, and physical harm, and achieve the effects of stable working state, reduced deformation, and good electrical conductivity.

Active Publication Date: 2022-06-03

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the results of the above-mentioned treatment of needle tips are very random, and it is often necessary to try multiple needle tips to succeed once.

In addition, hydrofluoric acid can also be used to remove the oxide layer on the surface of the tungsten tip (Yu Chang, Wang Hui. Vacuum Electronic Technology, 02, 31 (2004)), but hydrofluoric acid is extremely harmful to the human body, and this This method cannot avoid the re-formation of the oxide film after the treated needle tip contacts the air, and may introduce new organic pollution at the same time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

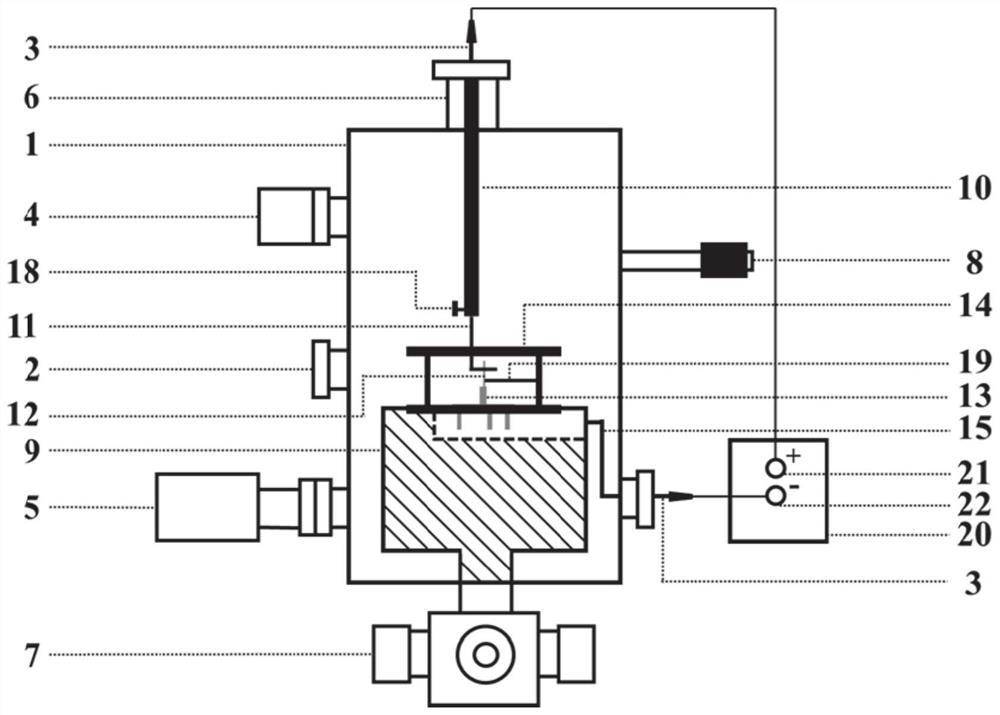

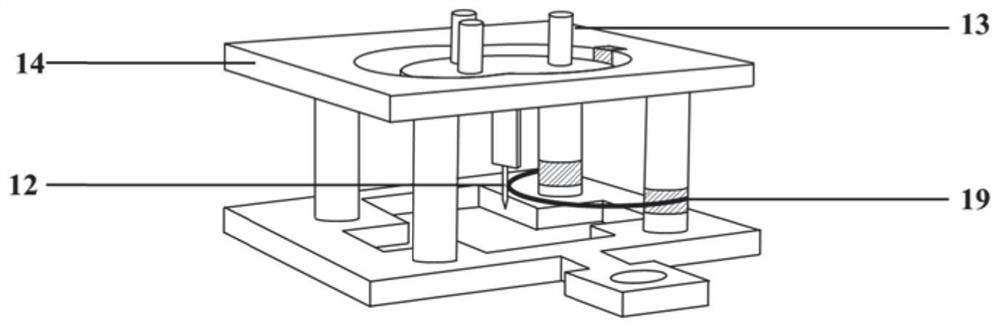

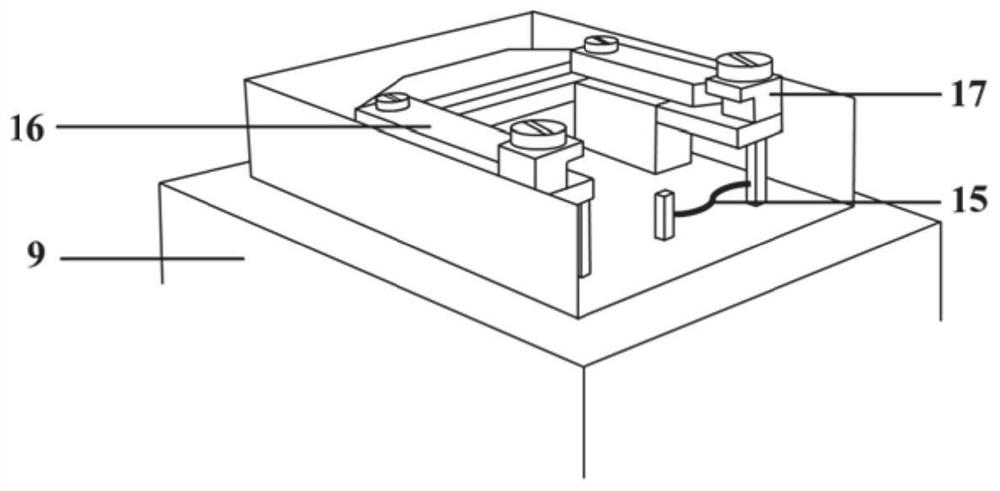

The invention relates to a needle point processing device of a scanning tunneling microscope, which comprises a vacuum cavity, an external power supply and an annealing assembly inside the vacuum cavity. The vacuum chamber includes the window flange, the flange with the circuit terminal, the pump unit and its interface flange, the vacuum gauge and its interface flange, the driving device for controlling the movement of the internal annealing tungsten wire and the driving device for controlling the position of the internal sample stage Device; the annealing assembly includes a tungsten wire, a support rod for fixing the tungsten wire, a needle support sample holder and a sample stage. The needle tip treatment device can anneal the needle tip of the scanning tunneling microscope under vacuum conditions, and can effectively pyrolyze and desorb the oxide layer and pollutants on the surface of the needle tip, thereby directly obtaining good electrical conductivity and stable working conditions inside the vacuum cavity. metal needle tip.

Description

A scanning tunneling microscope needle tip processing device technical field The invention belongs to the microscope field, be specifically related to a kind of scanning tunnel microscope that can realize annealing treatment in a vacuum cavity. A device for removing oxide layers and other contaminants from the tip of a micromirror tip. Background technique Scanning tunneling microscope is one of the important characterization methods of modern surface science. Researchers can observe the atomic arrangement and related physical and chemical properties on the material surface in real time. Scanning Tunneling Microscope mainly consists of a needle Tip, piezoelectric scanner, damping system and electronic control system (Chen Chengjun. Introduction to Scanning Tunneling Microscopy [M]. Beijing: China Light Industry Press, 1996). Among them, the shape and conductivity of the scanning tunneling microscope tip are related to the quality of the obtained images Closely re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01Q60/16G01Q70/16

CPCG01Q60/16G01Q70/16

Inventor 傅强张燃焜王东庆慕仁涛谭大力

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com