Battery self-discharge rapid screening method

A self-discharge and battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as low efficiency and long screening cycle, and achieve the effects of improving efficiency, shortening safety, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

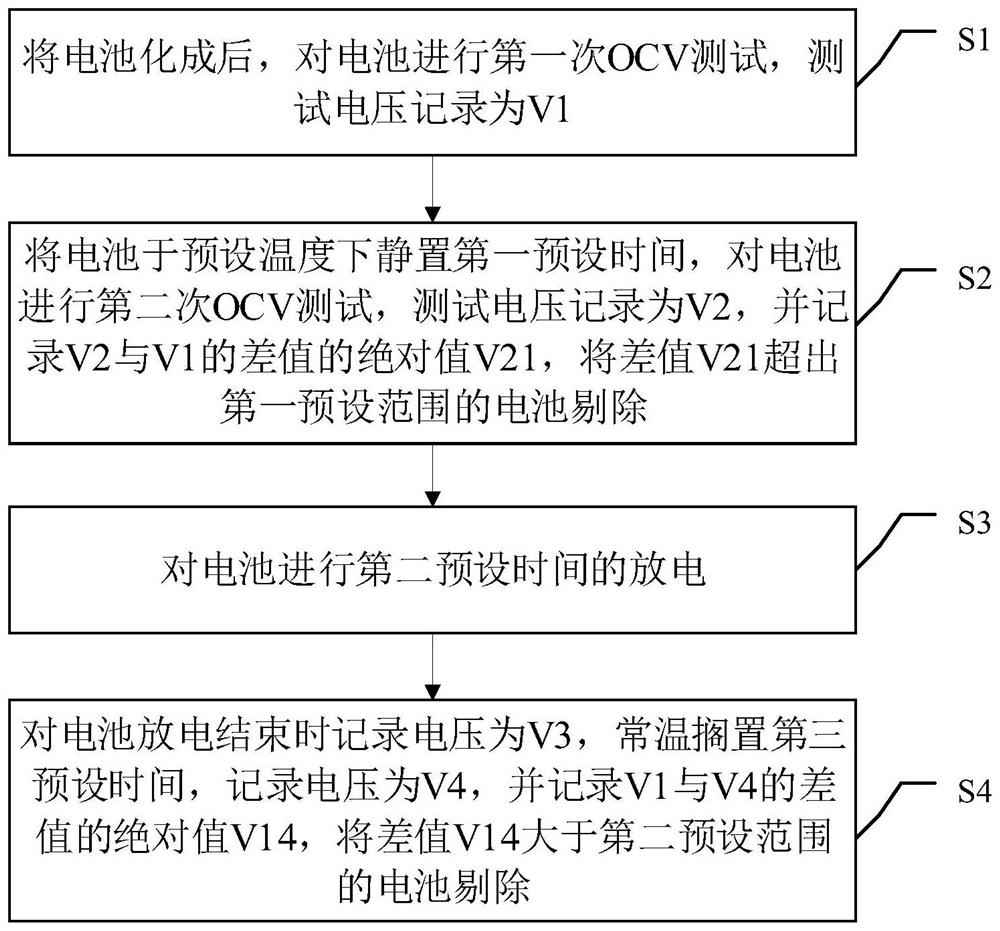

[0027] Such as figure 1 Shown, a kind of method for quick screening of battery self-discharge, described method comprises:

[0028] S1: After the battery is formed, the first OCV test is performed on the battery, and the test voltage is recorded as V1; the cut-off state of the battery formation is not lower than 50% SOC, and the SOC represents the state of charge of the battery.

[0029] S2: Let the battery stand at the preset temperature for the first preset time, conduct the second OCV test on the battery, record the test voltage as V2, and record the absolute value V21 of the difference between V2 and V1, and the difference V21 exceeds The battery removal in the first preset range, the first preset range is slightly different according to the battery model, so the first preset range is designed according to actual needs; specifically: put the battery at temperature T for x days, where x ≥1, T≥45°C, the preferred range of x is 1-3 days, and the preferred range of T is 45°C-...

Embodiment 2

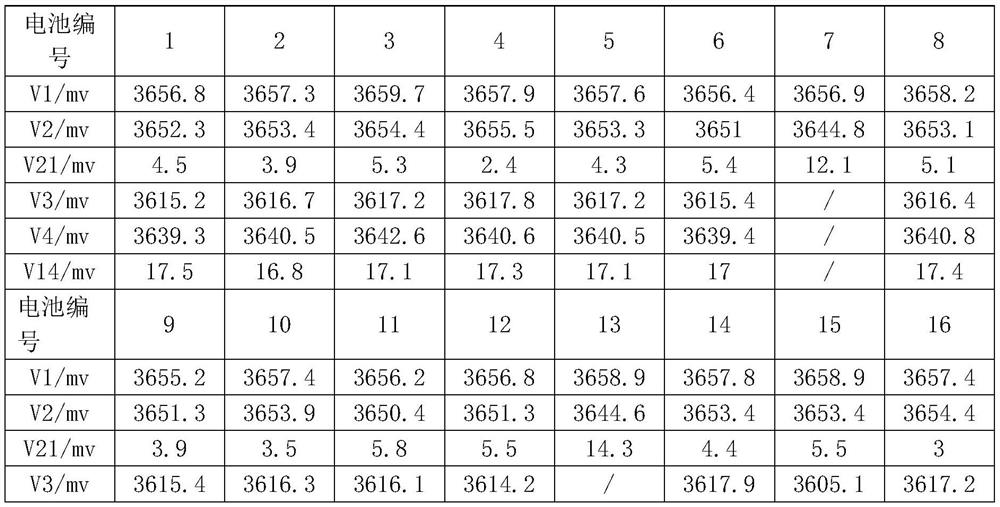

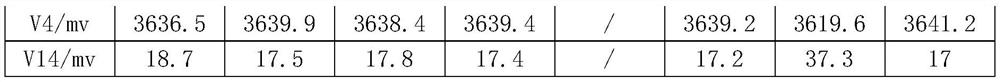

[0035] Embodiment 2 of the present invention is based on Embodiment 1, and provides a specific application example. Select a ternary 55Ah battery cell, form a cut-off state of 50% SOC, select 16 cells, conduct the first OCV test on the battery, and record the voltage V1, then put the battery in a high-temperature storage at 45°C for 2 days. After the battery cools down, conduct a second OCV test on the battery, record the voltage V2, calculate and record the difference V21 between the two voltage tests, and then place the battery on the DCR test cabinet Perform high-current discharge, set the current to 2C (55Ah batteries are used, so each C is 55A, and 2C is 110A), the discharge time is 10s, and the recorded voltage is V3 after the discharge. After the test, the battery is placed at room temperature (25°C ) After standing for 2 hours, conduct the third OCV test on the battery, record the voltage as V4, and calculate the difference V14 between the voltages of V1 and V4 at the s...

Embodiment 3

[0044] Embodiment 3 of the present invention is based on Embodiment 1, and provides another specific application example. Select a ternary 55Ah battery cell, form a cut-off state of 50% SOC, select 32 cells, conduct an OCV test on the battery, and record the voltage V1. Then put the battery in a high-temperature storage at 60°C for 1 day. After the battery is cooled, conduct a second OCV test on the battery, record the voltage V2, calculate and record the difference V21 between the two voltage tests, and then place the battery on the DCR test cabinet for large-scale testing. Current discharge, the current setting is 3C (55Ah batteries are used, so each C is 55A, 3C is 165A), the discharge time is 5s, and the recorded voltage is V3 after the discharge is completed. After the test is completed, the battery is placed at room temperature (25°C) After standing for 2 hours, carry out the third OCV test on the battery, record the voltage as V4, and calculate the voltage difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com