Preparation method of disodium fumarate

A technology of disodium fumarate and fumaric acid, which is applied in the preparation of carboxylate, carboxylate, and organic compounds, etc., which can solve the difficulties of crystallization of disodium fumarate, high product quality requirements, high solubility, etc. problems, to achieve the effect of saving turnover of infectious bacteria and foreign matter, improving product quality, and stabilizing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

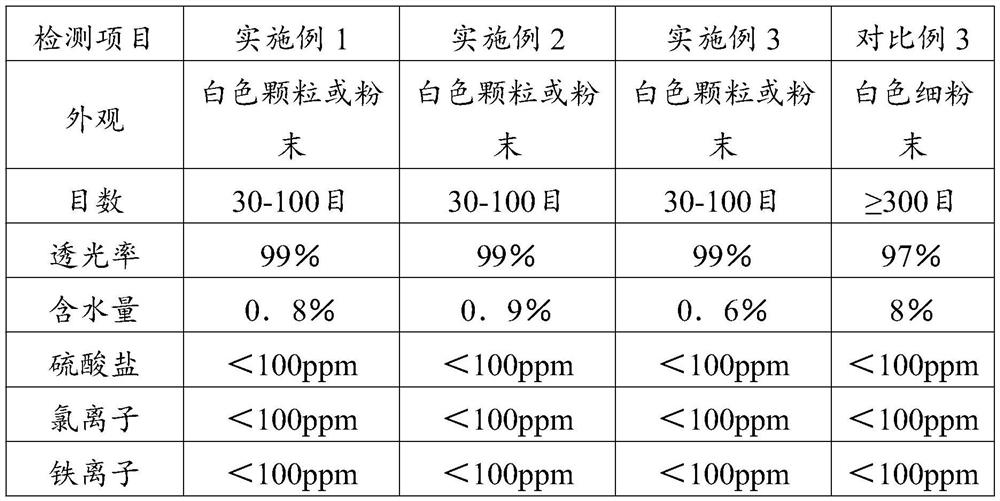

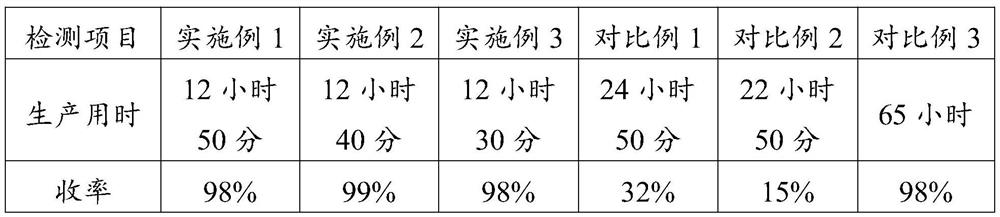

Examples

Embodiment 1

[0024] A preparation method of disodium fumarate, comprising the following steps:

[0025] (1) Add water to the reaction kettle, equipped with a motor to stir, heat to a temperature of 75°C, keep stirring, alternately add fumaric acid and sodium carbonate, the mass ratio is about 3:2, and the alternating interval is 5 minutes to prevent excessive foaming The feed liquid is splashed; the mass of fumaric acid is 30% of the mass of water, and the mass ratio of fumaric acid and sodium carbonate is 1:1. Take a small amount of reaction solution to filter and remove impurities, then test the pH, and correct the pH of the reaction solution to 6.5 (3 hours for feeding reaction); decolorize and filter the reaction solution (2 hours for decolorization and filtration), enter the vacuum concentration integrated tank to concentrate to solid cooling (time for reaction) 5 hours), at this moment the solid water content is about 8-10%.

[0026] (2) Transfer the solid to an oven, and dry it for...

Embodiment 2

[0029] A preparation method of disodium fumarate, comprising the following steps:

[0030] (1) Add water to the reaction kettle, equipped with a motor to stir, heat to a temperature of 75°C, keep stirring, alternately add fumaric acid and sodium carbonate, the mass ratio is about 3:2, and the alternating interval is 5 minutes to prevent excessive foaming The feed liquid is splashed; the mass of fumaric acid is 35% of the mass of water, and the mass ratio of fumaric acid and sodium carbonate is 1:1. Take a small amount of reaction solution to filter and remove impurities, then test the pH, and correct the pH of the reaction solution to 6.7 (3 hours for feeding reaction); decolorize and filter the reaction solution (2 hours for decolorization and filtration), enter the vacuum concentration integrated tank to concentrate to solid cooling (time for decolorization) 5 hours), at this moment the solid water content is about 6-8%.

[0031] (2) Transfer the solid to the boiling drying...

Embodiment 3

[0034] A preparation method of disodium fumarate, comprising the following steps:

[0035] (1) Add water to the reaction kettle, equipped with a motor to stir, heat to a temperature of 75°C, keep stirring, alternately add fumaric acid and sodium carbonate, the mass ratio is about 3:2, and the alternating interval is 5 minutes to prevent excessive foaming The feed liquid is splashed; the mass of fumaric acid is 40% of the mass of water, and the mass ratio of fumaric acid and sodium carbonate is 1:1. Take a small amount of reaction solution to filter and remove impurities, then test the pH, and correct the pH of the reaction solution to 6.7 (3 hours for feeding reaction); decolorize and filter the reaction solution (2 hours for decolorization and filtration), enter the vacuum concentration integrated tank to concentrate to solid (5 hours for the reaction). hours), at this time the solid moisture content is about 4-6%.

[0036] (2) Transfer the solid to the boiling drying pot, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com