Preparation method of high-sulfur-content lithium-sulfur battery positive electrode material

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of difficulty in realizing industrial production, low actual charge-discharge specific capacity, and low active material loading rate, etc., and achieve improved adsorption effect, enhanced chemical adsorption, and improved physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

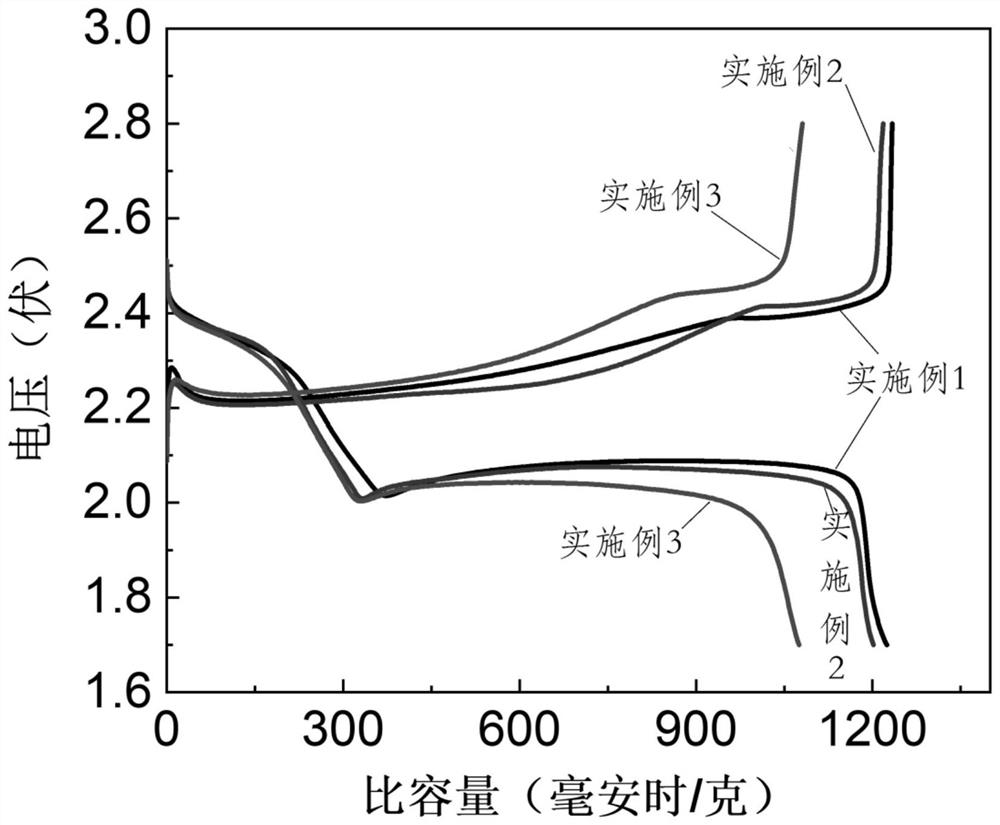

Embodiment 1

[0029] The preparation method of the high-sulfur lithium-sulfur battery cathode material comprises the following steps:

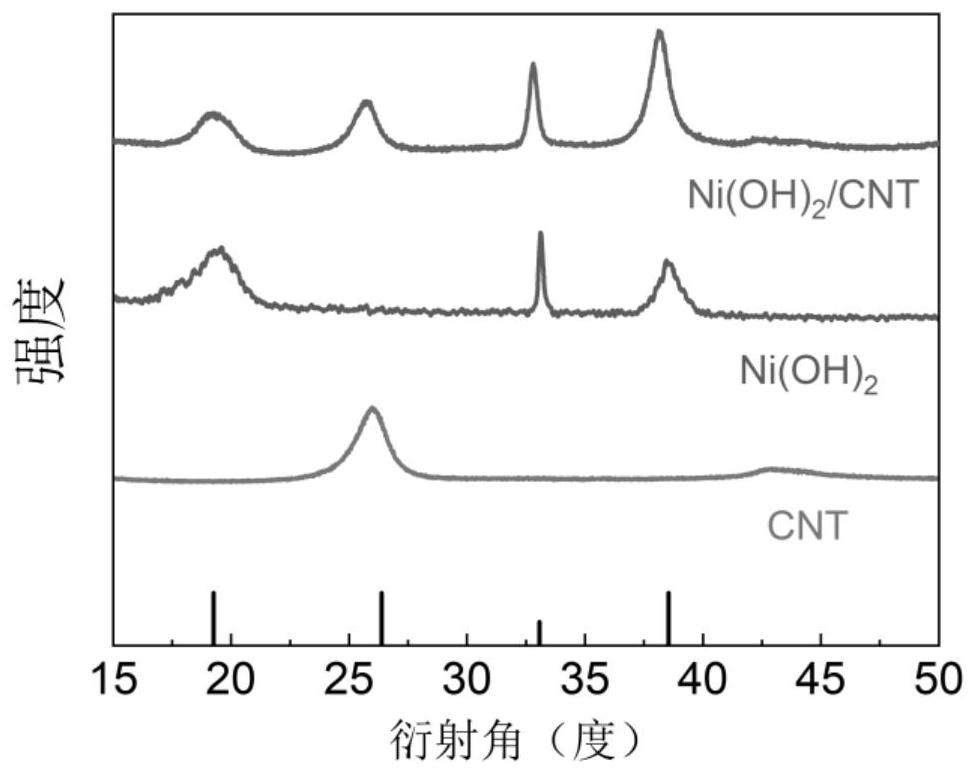

[0030] (1) Preparation of Ni(OH) 2 Precursor: First, 0.713g NiCl 2 ·6H 2 O and 1.802g urea were dissolved in 15mL deionized water respectively, and were configured to obtain nickel chloride solution and urea solution; the two solutions were mixed to form a light green solution, stirred for 30 minutes at a rotating speed of 300r / min; Under stirring, 6 mL of ammonia solution with a mass fraction of 13% was dropped dropwise into the light green solution to form a blue solution, namely Ni(OH) 2 Precursor;

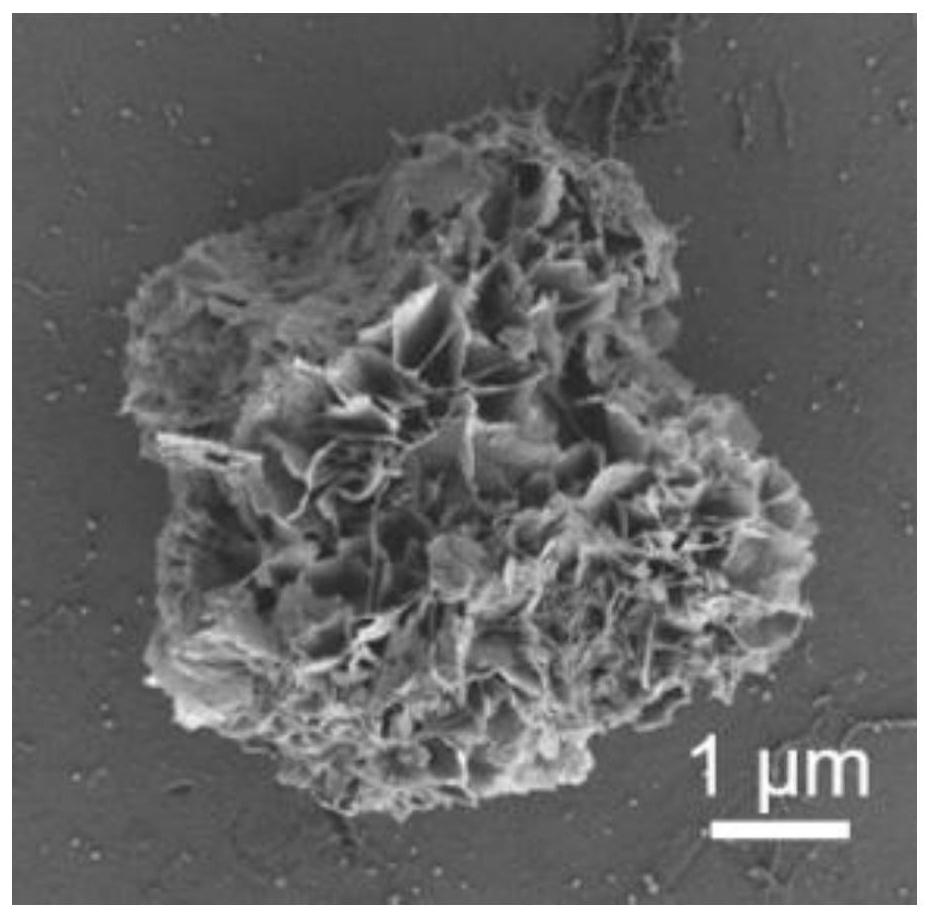

[0031] (2) Preparation of Ni(OH) 2 @CNT: First, take 800 mg of carboxylated multi-walled carbon nanotube water slurry containing 10% carbon nanotubes and disperse it in 30 mL of absolute ethanol. The ethanol solution was uniformly dispersed into the blue solution obtained in step (1) to form a dispersion; then the dispersion was transferred to a 150mL p...

Embodiment 2

[0038] The preparation method of the high-sulfur lithium-sulfur battery cathode material comprises the following steps:

[0039] (1) Preparation of Ni(OH) 2 Precursor: First, 0.713g NiCl 2 ·6H 2 O and 1.802g urea were dissolved in 15mL deionized water respectively, and were configured to obtain nickel chloride solution and urea solution; the two solutions were mixed to form a light green solution, stirred for 30 minutes at a rotating speed of 300r / min; Under stirring, 6 mL of ammonia solution with a mass fraction of 13% was dropped dropwise into the light green solution to form a blue solution, namely Ni(OH) 2 Precursor;

[0040] (2) Preparation of Ni(OH) 2 @CNT: First, take 600 mg of carboxylated multi-walled carbon nanotube water slurry containing 10% carbon nanotubes and disperse it in 30 mL of absolute ethanol. The ethanol solution was uniformly dispersed into the blue solution obtained in step (1) to form a dispersion; then the dispersion was transferred to a 150mL p...

Embodiment 3

[0043] The preparation method of the high-sulfur lithium-sulfur battery cathode material comprises the following steps:

[0044] (1) Preparation of Ni(OH) 2 Precursor: First, 0.713g NiCl 2 ·6H 2 O and 1.802g urea were dissolved in 15mL deionized water respectively, and were configured to obtain nickel chloride solution and urea solution; the two solutions were mixed to form a light green solution, stirred for 30 minutes at a rotating speed of 300r / min; Under stirring, 6 mL of ammonia solution with a mass fraction of 13% was dropped dropwise into the light green solution to form a blue solution, namely Ni(OH) 2 Precursor;

[0045] (2) Preparation of Ni(OH) 2 @CNT: First, take 800 mg of carboxylated multi-walled carbon nanotube water slurry containing 10% carbon nanotubes and disperse it in 30 mL of absolute ethanol. The ethanol solution was uniformly dispersed into the blue solution obtained in step (1) to form a dispersion; then the dispersion was transferred to a 150mL p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com