Laser direct forming method for spraying dielectric paint

A laser direct forming and dielectric technology, applied in the field of plastic metallization, can solve the problems of large metal line impedance and poor process precision, and achieve the effect of fewer models, high consistency, and fine resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

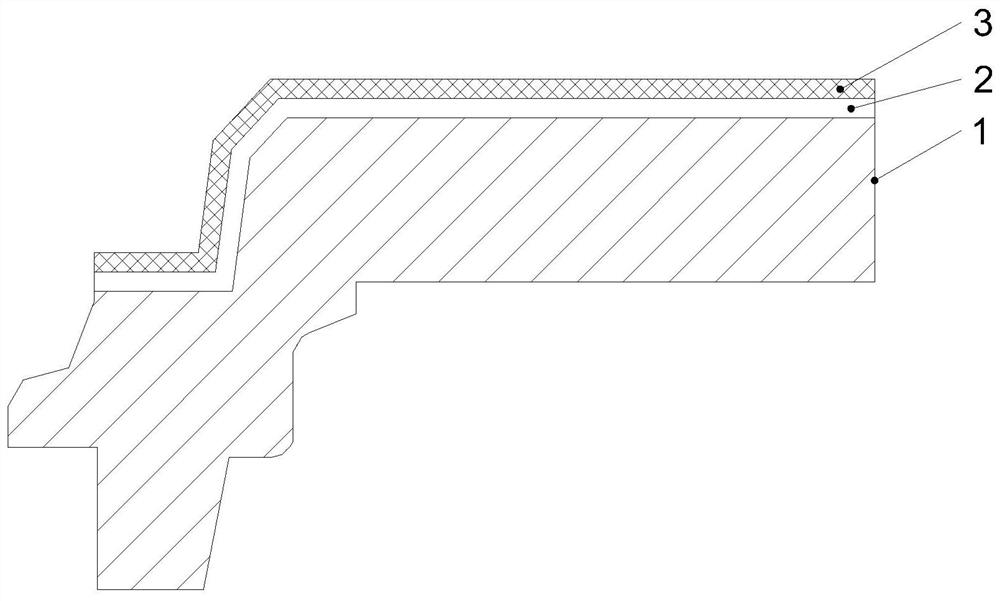

[0024] Example: such as figure 1 Shown, the present invention a kind of method for spraying medium lacquer laser direct forming, comprises the following steps:

[0025] Step 1: Select carrier 1;

[0026] Step 2: Use a spray gun to spray a layer of laser-capable dielectric paint on the surface of the carrier, and form a layer of paint film after high curing. The dielectric paint contains copper ions. After baking, the baking temperature is 100~ 120°C, the baking time is 120-480 minutes;

[0027] Step 3: Use laser to activate copper ions on the surface of the sprayed dielectric paint, and form circuits by activating and depositing metal.

[0028] Wherein, in step one, the carrier is glass.

[0029] Wherein, in step 1, the carrier is plastic.

[0030] Wherein, in step 1, the carrier is ceramics.

[0031] Among them, in step 2, before the carrier is sprayed, the surface of the carrier is cleaned to remove dust, and then it is dried. After the jig is assembled, the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com