Rubber glove

A technology of rubber gloves and rubber, which is applied in the direction of gloves, surgical gloves, rubber layered products, etc., can solve the problems of non-polar solvent resistance, poor workability, complicated manufacturing process, etc., and achieve excellent ease of operation, bonding High strength and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Hereinafter, examples related to the present invention will be described, but the present invention is not intended to be limited to the contents shown in the examples.

[0064] [Example and Comparative Example]

[0065] A mixed liquid containing the components shown in Table 1 was prepared using acrylonitrile-butadiene latex (“KNL870” manufactured by Kumho Corporation). An impregnating liquid A for inner layer formation was prepared by aging the mixed liquid for two days.

[0066] [Table 1]

[0067]

[0068] *Abbreviations in the table are as described below.

[0069] NBR: Acrylonitrile Butadiene Rubber

[0070] BZ: Zinc dibutyldithiocarbamate

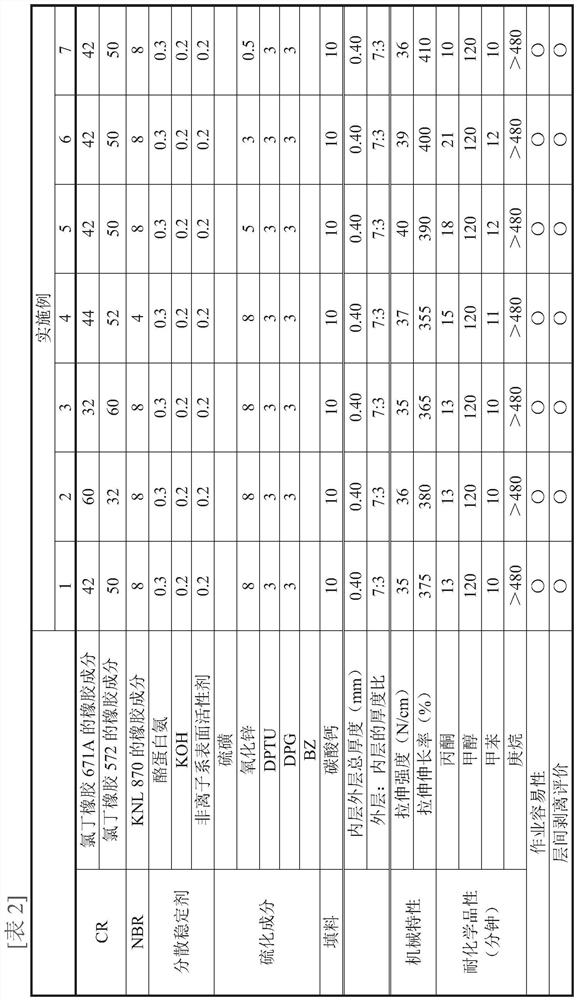

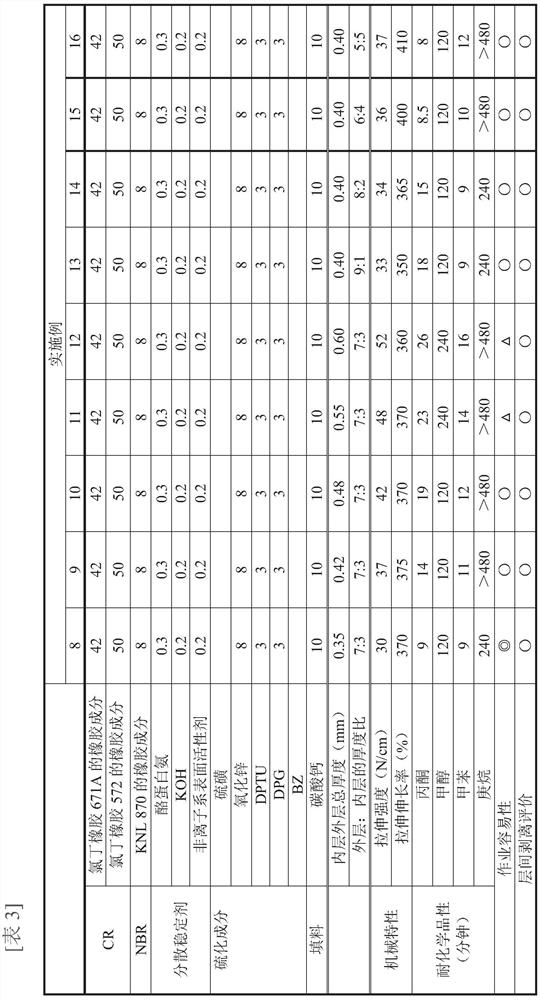

[0071] On the other hand, using acrylonitrile-butadiene latex "manufactured by KUMHO: KNL870", chloroprene latex "Neoprene 671A", and chloroprene latex "Neoprene 572", prepared A liquid mixture of the components shown in Tables 2 to 4. Impregnation solution B for outer layer formation was prepared by aging the mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com