A kind of large volume low hydration heat concrete and preparation method thereof

A low hydration heat, concrete technology, applied in the field of civil engineering, can solve the problems affecting the safety and normal use of concrete structures, multi-temperature cracks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

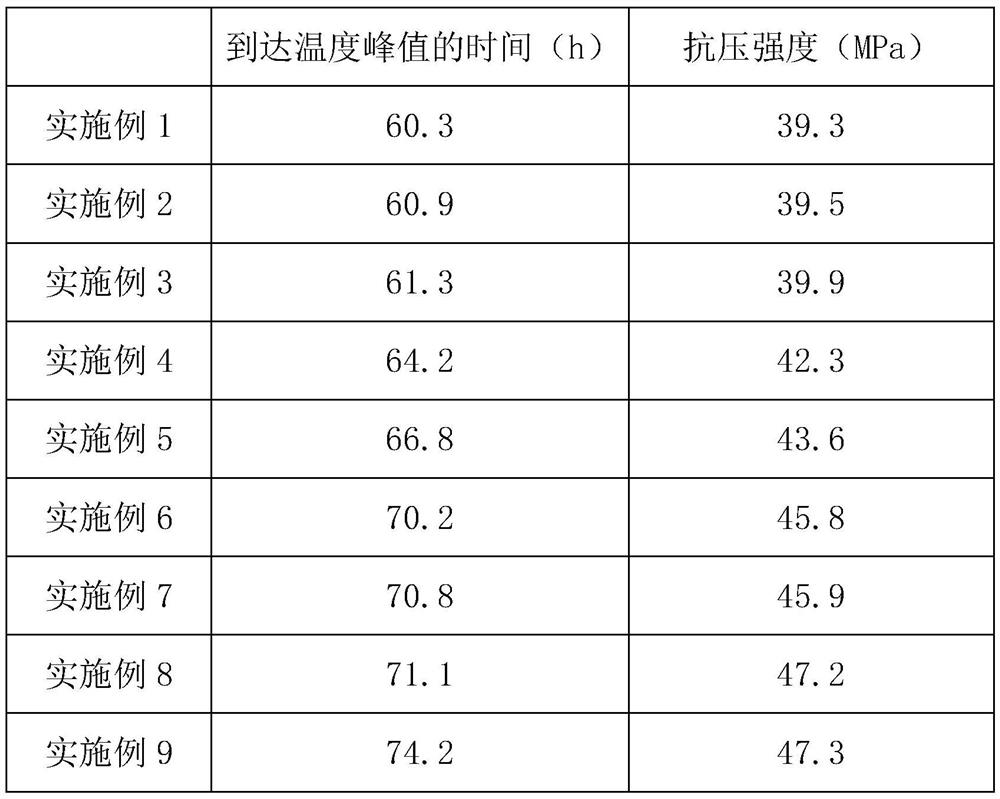

Examples

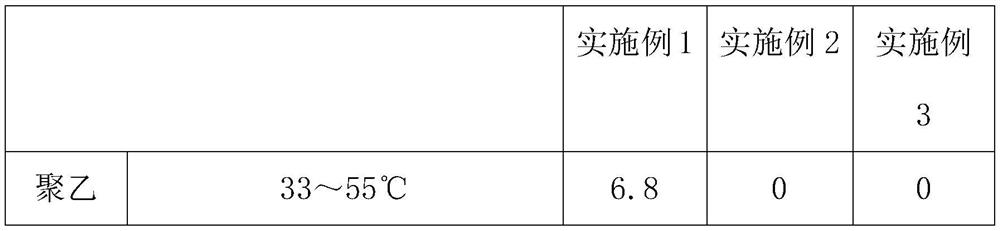

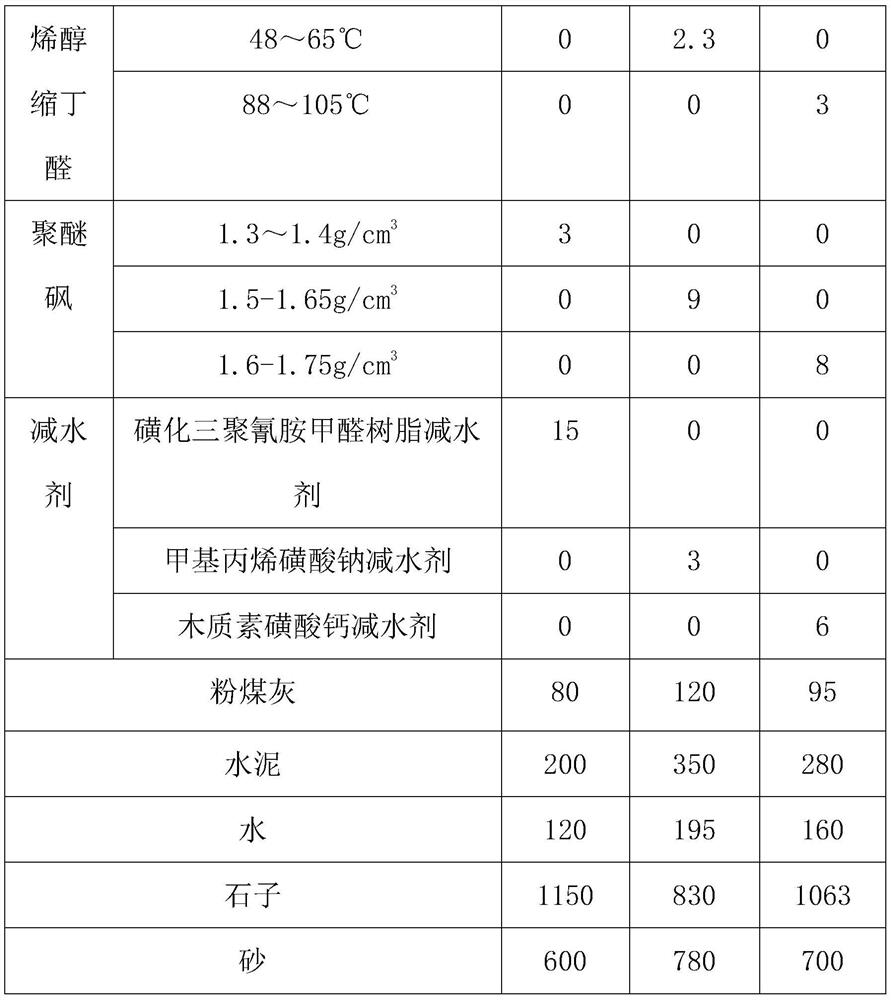

Embodiment 1

[0050] A high-volume, low-heat of hydration concrete is prepared by the following steps:

[0051]Step 1: after mixing cement, water and sulfonated melamine formaldehyde resin water reducing agent, rotate speed 100r / min, stir for 1.5h, and obtain the first mixture after mixing uniformly;

[0052] Step 2: adding sand, fly ash and stones to the first mixture, rotating at 130r / min, stirring for 1.5h, and mixing uniformly to obtain the second mixture;

[0053] Step 3: The polyvinyl butyral was heated to 84° C., and then added to the second mixture at a rotational speed of 150 r / min, and stirred for 0.5 h, and the third mixture was obtained after mixing uniformly.

[0054] Step 4: Heat the polyethersulfone to 250°C, add it to the third mixture, rotate at 120r / min, and stir for 2.5h. After mixing uniformly, a large volume of low-heat of hydration concrete is obtained.

Embodiment 2

[0056] A high-volume, low-heat of hydration concrete is prepared by the following steps:

[0057] Step 1: After mixing cement, water and sodium methacrylate water reducing agent, the rotating speed is 100r / min, stirring for 2.5h, and the first mixture is obtained after mixing uniformly;

[0058] Step 2: adding sand, fly ash and stones to the first mixture, rotating at 130r / min, stirring for 1h, and mixing uniformly to obtain the second mixture;

[0059] Step 3: The polyvinyl butyral was heated to 66° C., and then added to the second mixture at a rotational speed of 150 r / min, and stirred for 1 hour, and the third mixture was obtained after mixing uniformly.

[0060] Step 4: Heat the polyethersulfone to 200°C, then add it to the third mixture at a speed of 120r / min, and stir for 1 hour. After mixing evenly, a large volume of low-heat of hydration concrete is obtained.

Embodiment 3

[0062] A high-volume, low-heat of hydration concrete is prepared by the following steps:

[0063] Step 1: after mixing cement, water and calcium lignosulfonate water-reducing agent, the rotating speed is 100r / min, stirring for 2h, and the first mixture is obtained after mixing uniformly;

[0064] Step 2: adding sand, fly ash and stones to the first mixture, rotating at 130r / min, stirring for 1.3h, and mixing uniformly to obtain the second mixture;

[0065] Step 3: The polyvinyl butyral was heated to 75° C., and then added to the second mixture at a rotational speed of 150 r / min, and stirred for 0.8 h, and the third mixture was obtained after mixing uniformly.

[0066] Step 4: Heat the polyethersulfone to 230°C, add it to the third mixture, rotate at 120r / min, and stir for 2h. After mixing uniformly, a large-volume low-heat of hydration concrete is obtained.

[0067] Wherein, in embodiment 1-3, the water reducing agent adopts one of sulfonated melamine formaldehyde resin water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com