Waterproof concrete pipe and preparation method thereof

A waterproof concrete and pipe technology, applied in the field of concrete pipes, can solve the problems of complicated waterproof measures and poor waterproof effect, and achieve the effects of good waterproof and anti-corrosion effect, reduced risk of cracking, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

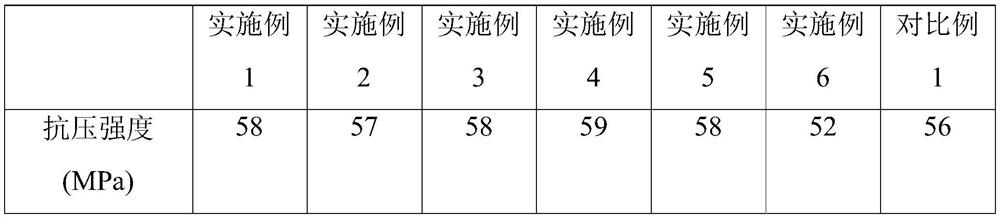

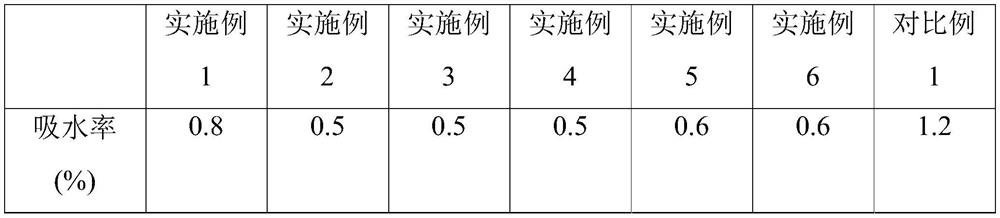

Examples

Embodiment 1

[0036] A method of preparing a waterproof concrete pipe provided in this example, comprising the steps of:

[0037] 1) Weighing, stirring: the raw material is weighing according to the material ratio of the waterproof concrete pipe of Table 1, wherein the octylsilane waterproof agent is a normal octyltriboxyzoxysilane emulsion. The concentration of the n-octyltriethoxysilane emulsion was 40%. The solid raw material was placed in a stirrer, stirred for 0.5 minutes, and then the liquid raw material was added, and stirring was continued for 1 minute to give a mixture.

[0038] 2) Carter formation: Put the mixture into the mold, add steel bib, and the core molding, and the waterproof concrete pipe is made.

[0039] 3) Steam, demultiplexing: At normal pressure, the crude product is placed in the steam pool, and after 3 hours at a temperature of 22 ° C, the temperature rise rate is warmed at 20 ° C / h. 60 ° C, at which the temperature was 4 hours under this temperature; then the waterp...

Embodiment 2

[0042] A method of preparing a waterproof concrete pipe provided in this example, comprising the steps of:

[0043] 1) Weighing, stirring: the raw material is weighing according to the material ratio of the waterproof concrete pipe of Table 1, wherein the octylsilane waterproof agent is a normal octyltriboxyzoxysilane emulsion. The concentration of the n-octyltriethoxysilanous emulsion was 60%. After placing the solid raw material into the mixer, stirred for 1 minute, then the liquid raw material was added, and stirring was continued for 2 minutes to give a mixture.

[0044] 2) Carter formation: Put the mixture into the mold, add steel bib, and the core molding, and the waterproof concrete pipe is made.

[0045] 3) Steam, demultiplexing: The hydrophilic concrete pipe is placed in the steam pool under normal pressure, and after 2 hours at a temperature of 25 ° C, the temperature rise rate is heated at 25 ° C / h. 90 ° C, at this temperature conditions for 3 hours; then cool down to...

Embodiment 3

[0048] A method of preparing a waterproof concrete pipe provided in this example, comprising the steps of:

[0049] 1) Weighing, stirring: the raw material is weighing according to the material ratio of the waterproof concrete pipe of Table 1, wherein the octylsilane waterproof agent is a normal octyltriboxyzoxysilane emulsion. The concentration of the n-octyltriethoxysilanous silicone emulsion was 50%. The solid raw material was placed in a mixer, stirred for 1 minute, then adding liquid raw materials, continued for 4 minutes to give a mixture.

[0050] 2) Carter formation: Put the mixture into the mold, add steel bib, and the core molding, and the waterproof concrete pipe is made.

[0051] 3) Steam, demultiplexing: The crude material of the waterproof concrete pipe is placed in the steam pool under normal pressure, and after 2 hours at a temperature of 25 ° C, the temperature rise rate at 23 ° C / hr. 70 ° C, at which the temperature was 3 hours; then the waterproof concrete pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com