Reciprocating type disc plucking device of opening machine for textile production and use method of reciprocating type disc plucking device

A reciprocating, disc technology, applied in the textile field, can solve the problems of difficulty in maintaining the best position between the top surface and the beater, sparks easily generated by mutual friction, and low space utilization, so as to improve the safety of use, prevent mechanical wear, The effect of improving the fineness of cotton beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

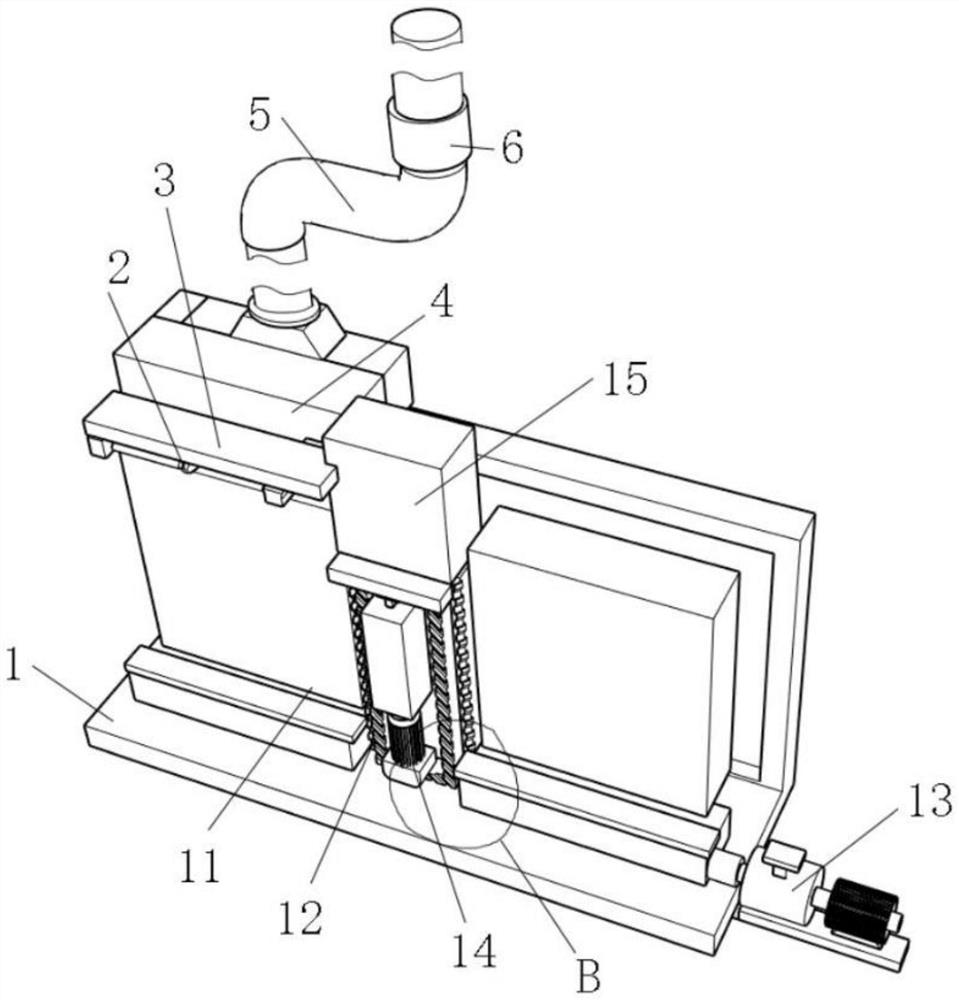

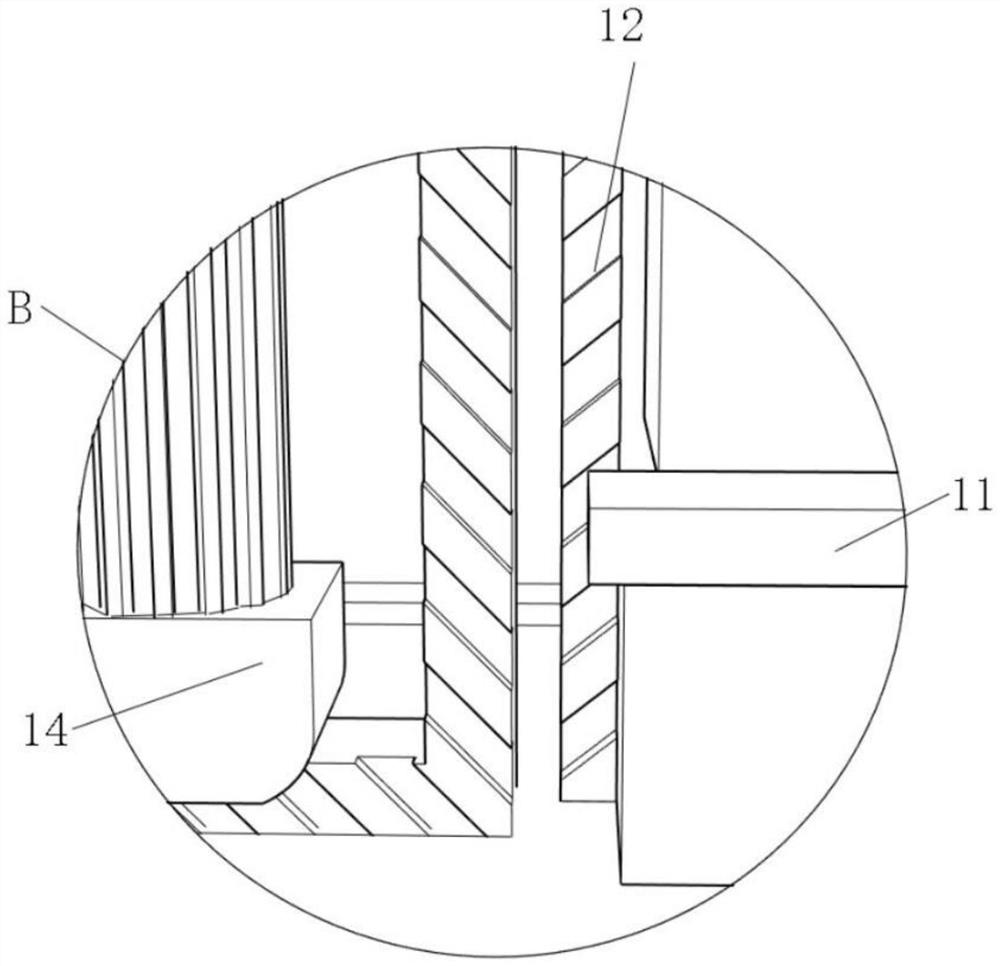

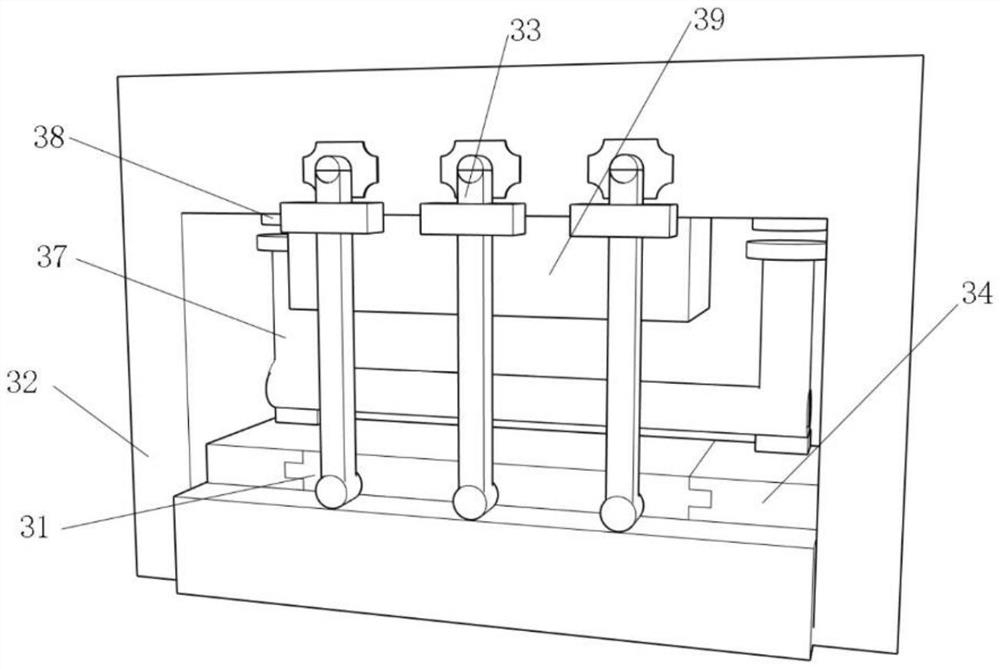

[0036] as attached figure 1 to attach Figure 7 Embodiments of the present invention provide an open-faced machine reciprocating disc grabbing device for textile production and its use method, including a cotton box 1, a rotating mounting column 15 is fixedly installed on the top surface of the cotton box 1, and the rotating mounting column One side of 15 is fixedly equipped with a cotton grasping mechanism 4, and the outer side of the cotton grasping mechanism 4 is fixedly installed with an iron removal mechanism 2 and an iron collection mechanism 3. The iron removal mechanism 2 is located at the bottom of the iron collection mechanism 3, and the top surface of the cotton grasping mechanism A cotton guide pipe 5 is fixedly installed, and a pipe connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com