Length-variable connecting rod device

A connecting rod device, a variable technology, applied in the direction of connecting rods, shafts and bearings, combustion engines, etc., can solve the problems of huge changes in production lines, failure to use engines, poor versatility, etc., achieve less processing procedures, improve switching responsiveness, The effect of reducing oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

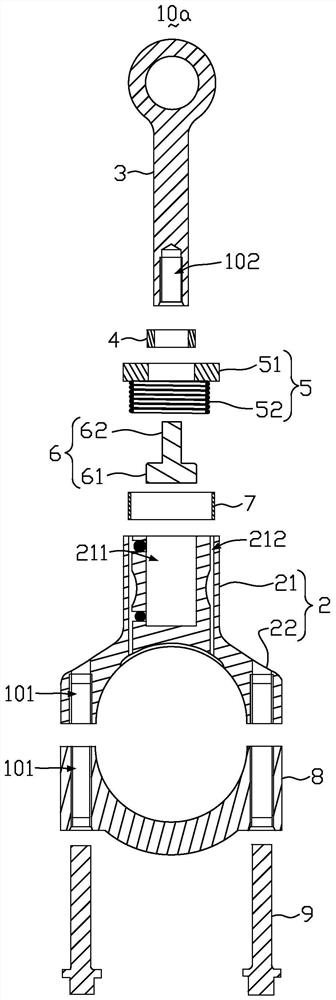

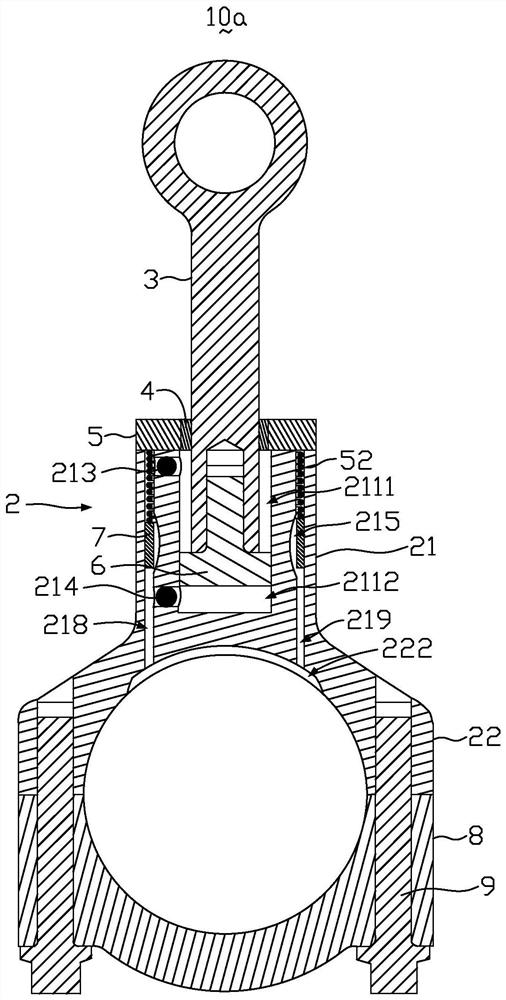

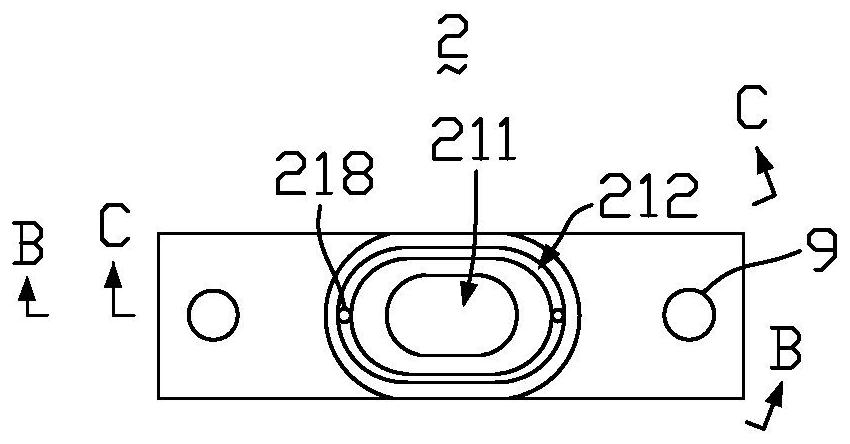

[0034] figure 1 It is an exploded view of the variable-length link device of the first embodiment of the present invention. figure 2 It is a structural schematic diagram of the length-variable link device according to the first embodiment of the present invention. Such as figure 1 with 2 As shown, the variable-length connecting rod device 10a includes a large-end connecting rod body 2, a small-end connecting rod body 3, a first sealing ring 4, a spring valve body 5, a transmission shaft 6, a second sealing ring 7, and a connecting rod cover 8 and connecting rod bolts 9. The transmission shaft 6 is movably arranged in the large end connecting rod body 2 , a part of the transmission shaft 6 is connected with the large end connecting rod body 2 , and the other part is connected with the small end connecting rod body 3 . The first sealing ring 4 is set on the spring valve body 5, the small end connecting rod body 3 passes through the first sealing ring 4 and is connected with...

no. 2 example

[0046] The structure of the variable-length connecting rod device 10b of the second embodiment of the present invention is the same as the structure of the variable-length connecting rod device 10a of the first embodiment, except that the oil chamber 211 and the first oil groove 212 of this embodiment are And the cross section of the transmission shaft 6 is circular. The working principle of the variable-length link device 10b of this embodiment is the same as the working principle of the variable-length link device 10a of the first embodiment, please refer to the description of the variable-length link device 10a of the first embodiment The working principle will not be elaborated here.

[0047]The variable-length connecting rod device 10a, 10b telescopic principle of the present invention consists of an oil chamber 211, a first oil groove 212, a first one-way valve 213, a second one-way valve 214, a second oil groove 215, a first oil passage 216, The second oil passage 217,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com