Carbon-carbon composite material production device and production process

A carbon composite material and production equipment technology, applied in the field of carbon-carbon composite material production equipment and its production process, can solve the problems of low mixing efficiency, easy to cause blockage, affecting the discharge efficiency of the device, etc., to achieve high mixing efficiency and improve The effect of discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

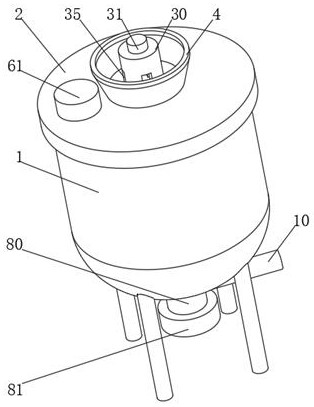

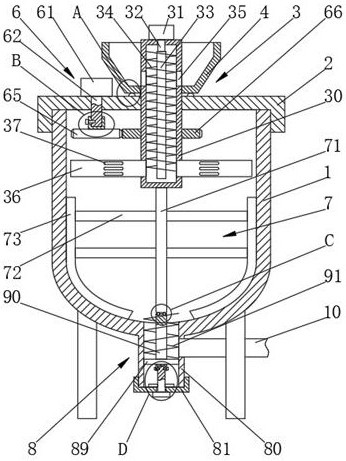

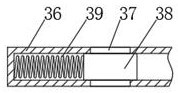

[0034] Carbon-carbon composite material production equipment, including a kettle body 1, a kettle cover 2 is connected to the kettle body 1 through threads, a feeding mechanism 3 is installed on the kettle cover 2, and a material is arranged on the outside of the feeding mechanism 3 Bucket 4, described kettle cover 2 is provided with drive mechanism 6, and described drive mechanism 6 comprises motor 61, and described motor 61 is fixedly connected with kettle cover 2, and described motor 61 is provided with drive shaft 62, and described kettle cover 2. The drive shaft 62 is connected in rotation, and the outside of the drive shaft 62 is slidably connected with a connecting sleeve 63. A gear 65 is welded on the connecting sleeve 63, and a gear ring 66 is meshed on the gear 65. The gear ring 66 is fixedly sleeved with a twisted cage 30 , the feeding mechanism 3 is provided with a stirring mechanism 7 , the kettle body 1 is provided with a discharge mechanism 8 , and the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com