Water-based base layer treating agent composition, water-based base layer treating agent and preparation method and application of water-based base layer treating agent

A basic treatment agent and composition technology, applied in coatings, building components, building thermal insulation materials, etc., can solve the problems of poor bonding performance, water channeling, existence, etc., so as to reduce the possibility of water channeling and enhance the bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

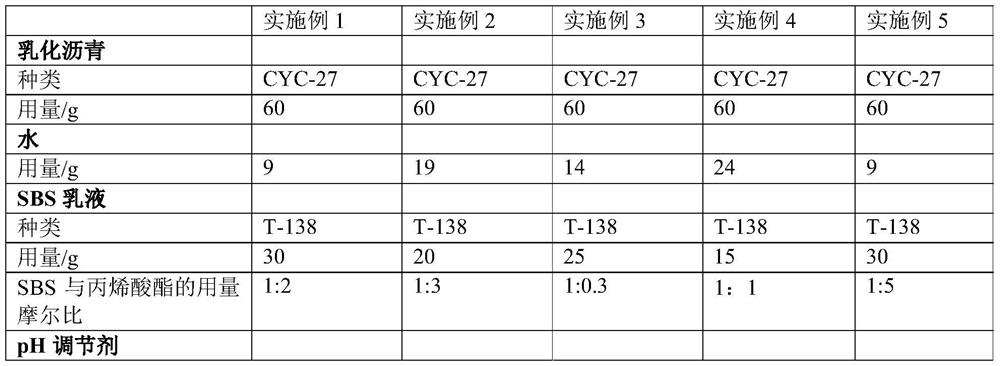

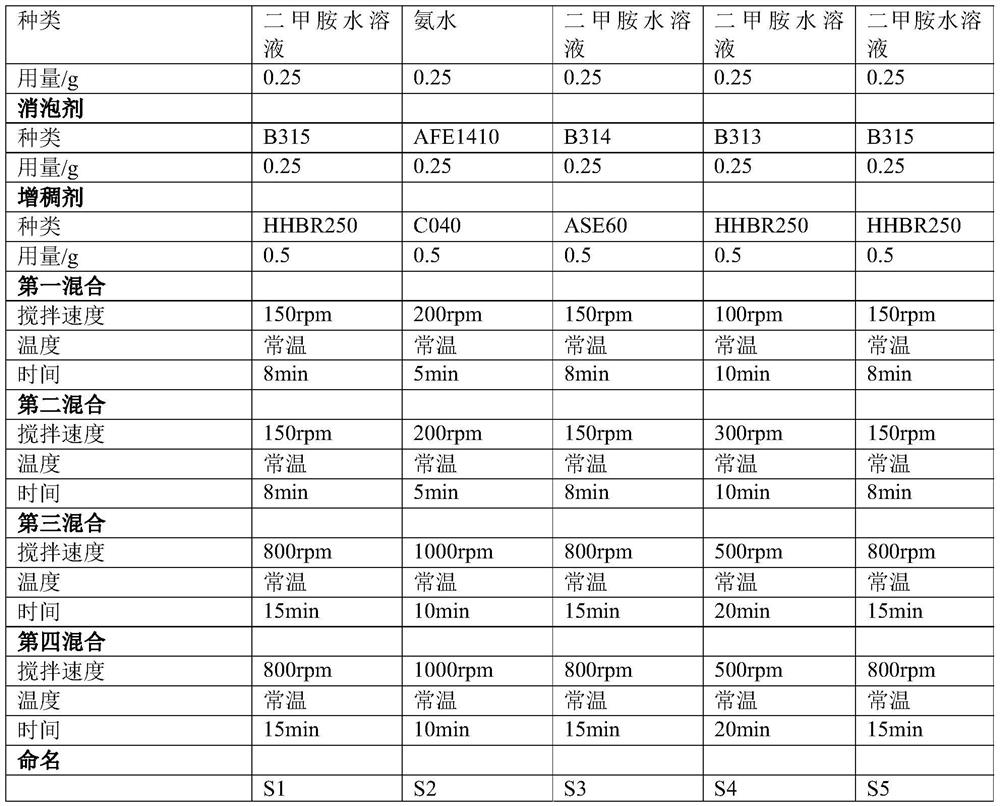

[0063] This example is used to illustrate that the water-based base treatment agent composition according to the present invention is prepared according to the formula and process parameters in Table 1, and the water-based base treatment agent is prepared according to the following method.

[0064] The method for preparing the water-based base treatment agent comprises the following steps:

[0065] (1) Stir the water and the thickener at 150 rpm for 8 minutes at normal temperature to obtain the first mixture;

[0066] (2) Stir the first mixture obtained above and the pH regulator at 150 rpm for 8 minutes at normal temperature to obtain the second mixture;

[0067] (3) at normal temperature, the second mixture obtained above was stirred with SBS emulsion and defoamer at 800rpm for 15min to obtain the third mixture;

[0068] (4) At room temperature, the third mixture obtained above and the emulsified asphalt were stirred at 800 rpm for 15 minutes to obtain the water-based base ...

Embodiment 5

[0071] In this example, a water-based base treatment agent is prepared using a formula and method similar to that of Example 1, except that in the SBS emulsion, the molar ratio of the amount of SBS to the acrylate is 1:5, see the table for details 1.

Embodiment 6

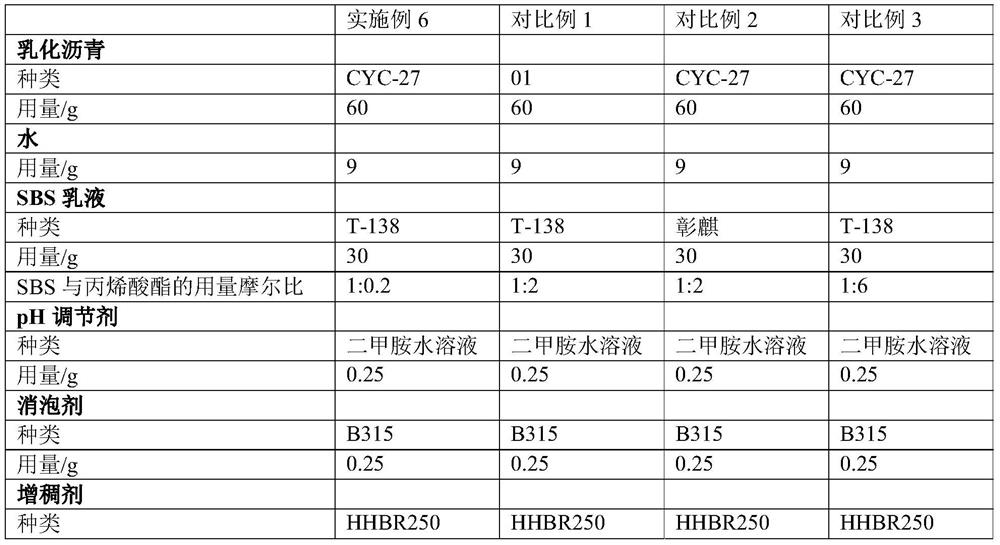

[0073] This example adopts the formula and method similar to Example 1 to prepare the water-based base treatment agent, the difference is: in the SBS emulsion, the molar ratio of the SBS to the acrylate is 1:0.2, see the table for details 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com