Acid-reducing microbial soil conditioner as well as preparation method and application thereof

A soil improver and microbial technology, applied in the field of acid-reducing microbial soil improver and its preparation, can solve the problems of reducing ammonifying bacteria and nitrogen-fixing bacteria, affecting the virtuous cycle of nutrient elements, and reducing the growth of individual bacteria, so as to prevent soil Effects of secondary acidification, realization of resource utilization, improvement of soil acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] A preparation method of an acid-reducing microbial soil improver, comprising the steps of:

[0041] (1) Preparation of modified calcium carbide slag: first dry the carbide slag at 105°C for 1 hour, then place it in a horse-boiling furnace for calcination at 300°C for 2 hours, cool to room temperature after completion, and grind it in a grinder for 5 minutes to obtain modified carbide slag powder.

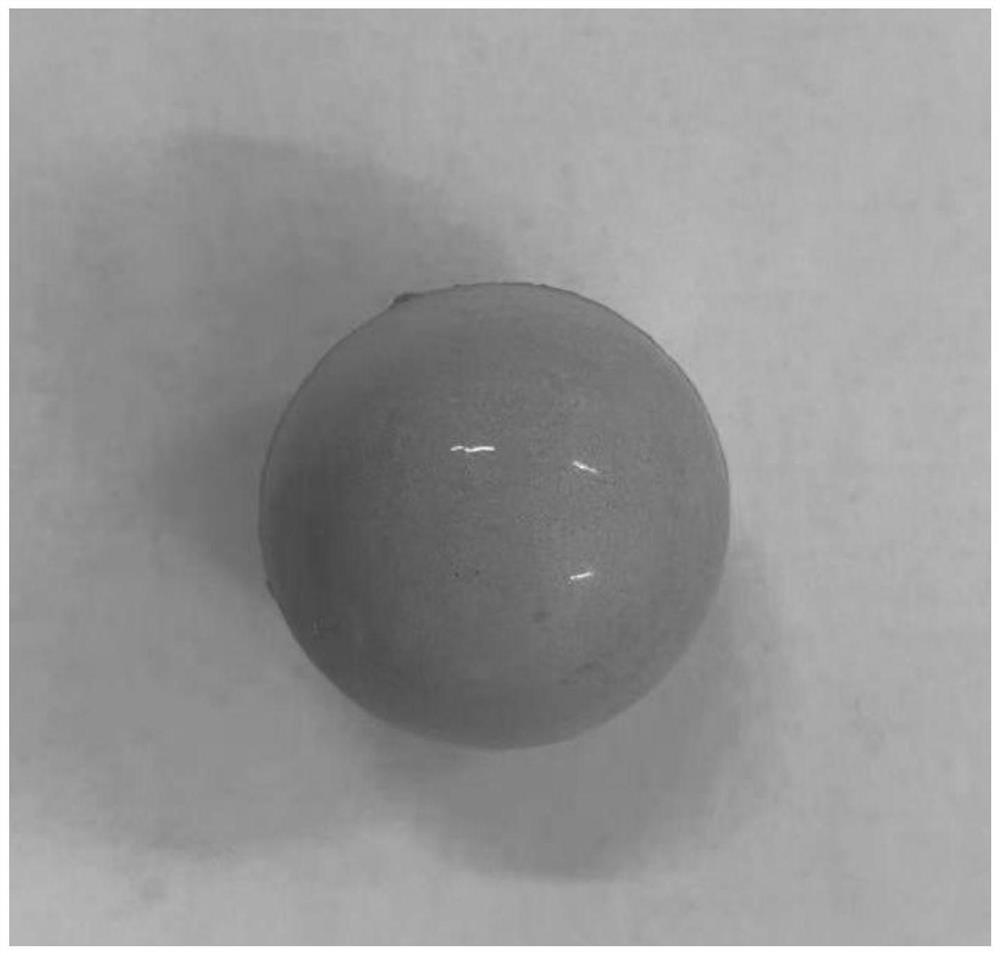

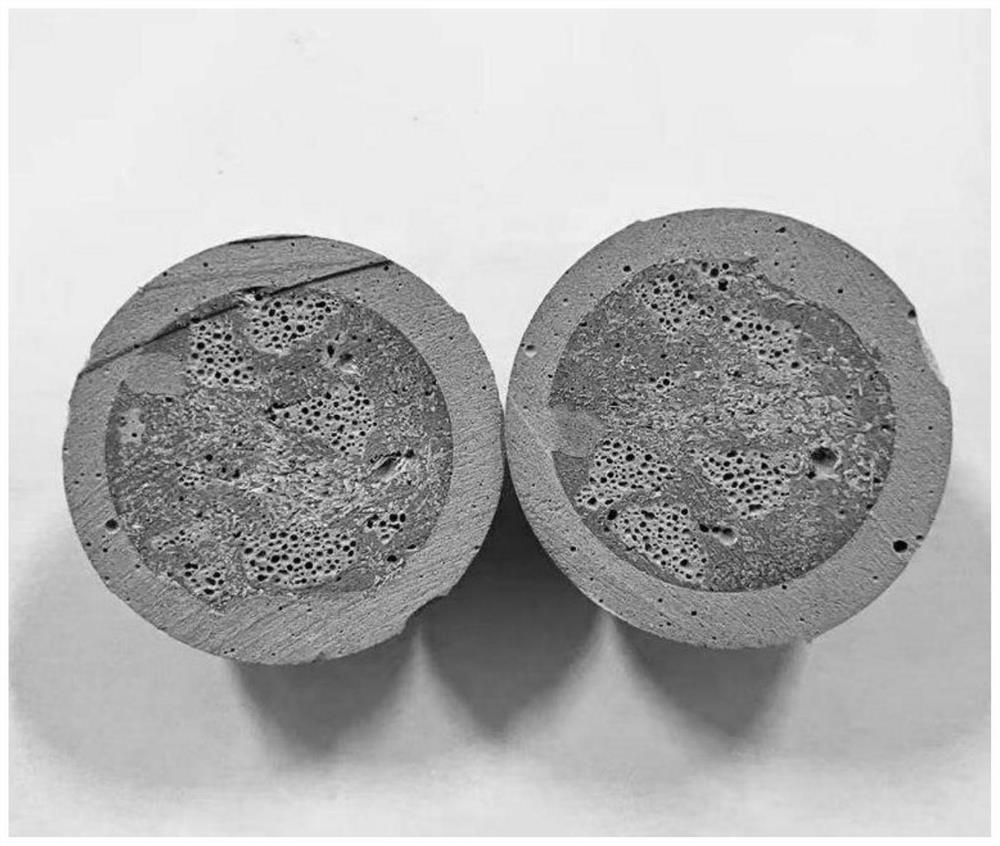

[0042] (2) Acid-reducing microparticles: Mix 0.5 parts by weight of hydrogen peroxide and 5 parts by weight of water evenly, then add 5 parts by weight of tricalcium silicate and 50 parts by weight of the modified carbide slag prepared in step (1), and stir them evenly at 20°C and relative humidity of 60% for curing for 10 hours. After completion, the porous particles with a diameter of less than 3 mm are obtained by crushing. After mixing 50 parts by weight of modified calcium carbide slag and 5 parts by weight of water, they are mixed with the porous particles to make the m...

no. 2 example

[0046] A preparation method of an acid-reducing microbial soil improver, comprising the steps of:

[0047] (1) Preparation of modified calcium carbide slag: first dry carbide slag at 100°C for 3 hours, then place it in a horse-boiling furnace for calcination at 550°C for 0.5 hour, cool to room temperature after completion, and place it in a grinder for grinding for 10 hours. minutes to obtain modified carbide slag powder.

[0048] (2) Acid-reducing microparticles: Mix 5 parts by weight of hydrogen peroxide and 10 parts by weight of water evenly, then add 15 parts by weight of tricalcium silicate and 65 parts by weight of modified carbide slag prepared in step (1) and relative humidity of 40% for curing for 18 hours, and then broken to obtain porous particles with a diameter of less than 3 mm. Mix 65 parts by weight of modified calcium carbide slag and 10 parts by weight of water with the porous particles to make the modified calcium carbide The slag fills the pores of the por...

no. 3 example

[0052] A preparation method of an acid-reducing microbial soil improver, comprising the steps of:

[0053] (1) Preparation of modified calcium carbide slag: first dry the carbide slag at 120°C for 1 hour, then place it in a horse-boiling furnace for calcination at 450°C for 1.5 hours, cool to room temperature after completion, and place it in a grinder for grinding for 10 minutes to obtain modified carbide slag powder.

[0054] (2) Acid-reducing microparticles: Mix 4.5 parts by weight of hydrogen peroxide and 7 parts by weight of water evenly, then add 7 parts by weight of tricalcium silicate and 57 parts by weight of the modified carbide slag prepared in step (1), and stir them uniformly at 28°C and relative humidity of 55% for curing for 15 hours. After completion, the porous particles with a diameter of less than 3 mm were obtained by crushing. After mixing 59 parts by weight of modified calcium carbide slag and 8 parts by weight of water, they were mixed with the porous pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com