Upper deslagging system on full-section vertical shaft heading machine

A roadheader and full-section technology, applied in shaft equipment, sinking, mining equipment, etc., can solve the problems of large space occupied by motors, pump bodies and pipelines, low efficiency of slag discharge, limited space, etc., and shorten continuous conveying Length, reduce pump suction pressure, increase the effect of slag discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

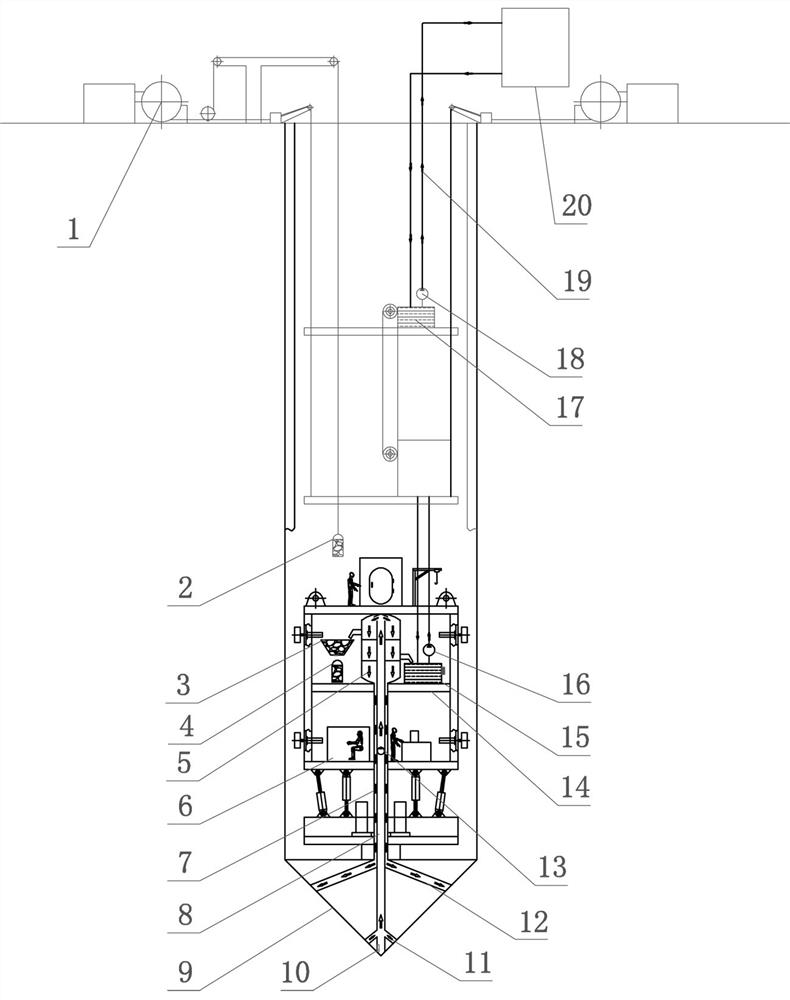

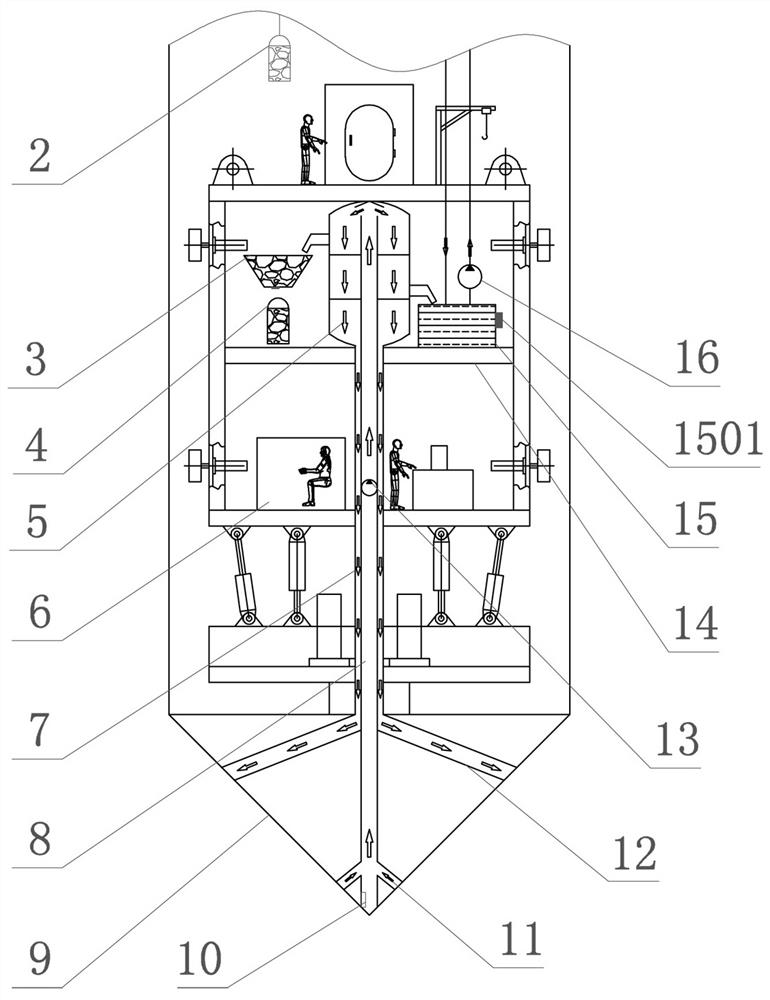

[0029] Such as Figure 1 to Figure 4 As shown, the slag discharge system on the full-face shaft boring machine of this embodiment includes a cutter head 9, and the cutter head 9 is provided with a jet port 12 for spraying liquids such as clear water or mud to the shaft section when the cutter head 9 is tunneling, and a The slag suction port 11 and the center of the cutter head 9 are provided with a multi-layer casing type center column at the center of the slag suction port 11 for absorbing the slurry produced at the shaft section, and the multi-layer casing type center column includes a slag suction pipe 8 communicated with the slag suction port 11 and The jet pipe 7 is sleeved outside the slag suction pipe 8 and communicated with the jet port 12 for providing flushing liquid to the jet port 12, and a ring shape is formed between the jet pipe 7 and the slag suction pipe 8 for the flushing liquid to flow therein. aisle.

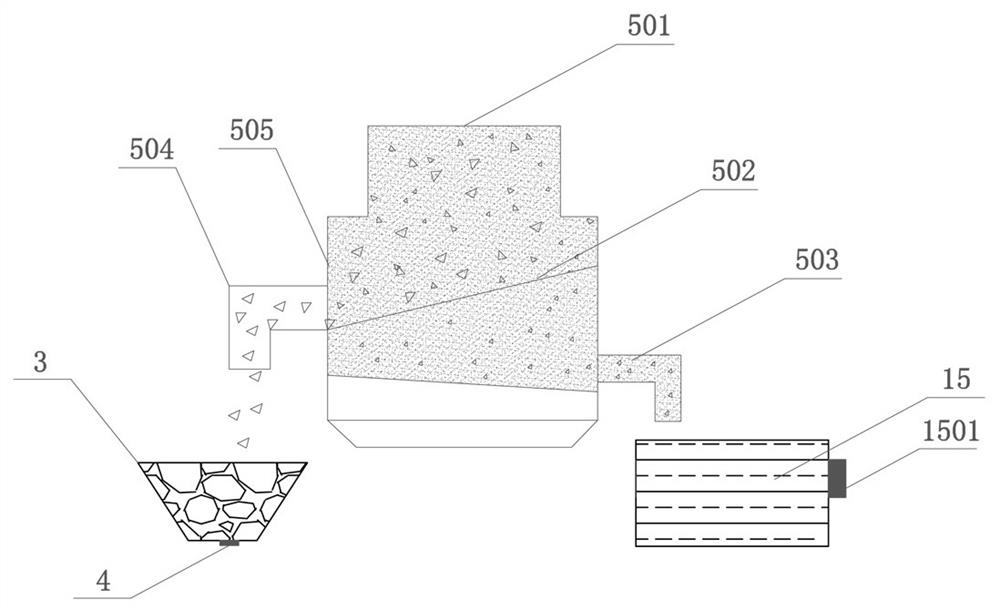

[0030] The upper slag discharge system of this embodim...

Embodiment 2

[0038] The slag discharge system on the full-face shaft boring machine of this embodiment is different from that of Embodiment 1 in that the solid storage bin 3 can be fixed on the relay platform 14 during implementation, and the bottom of the solid storage bin 3 is provided for detecting solids. The gravity sensor 4 of the weight of the storage bin 3, when the rock slag enters the solid storage bin 3, the signal of the gravity sensor 4 can feed back the amount of the rock slag accumulated in the solid storage bin 3, in the liquid storage bin 15 There is a liquid level gauge 1501 for detecting the height of the slurry in the liquid storage bin 15. By setting the gravity sensor and the liquid level gauge 1501, when the rock slag in the solid storage bin 3 reaches the set weight, start the winch 1 to lift the bucket 2 Put it down and hang out the rock slag in the solid storage bin 3. When the liquid level gauge 1501 reaches the set liquid level, you can turn on the slurry pump 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com