A kind of pneumatic environment-friendly coal particle drying equipment

A kind of particle drying and environment-friendly technology, applied in the direction of non-progressive dryers, drying chambers/containers, drying solid materials, etc., can solve the problems of small turning range, limited lifting height, and affecting the drying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

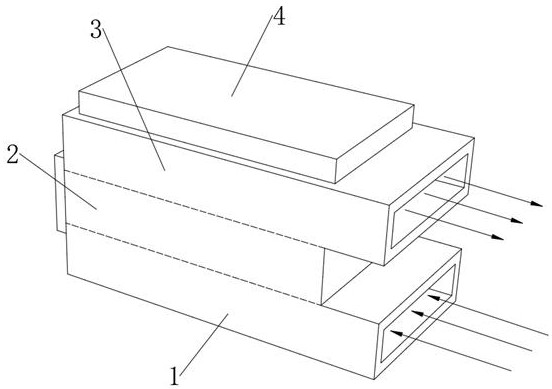

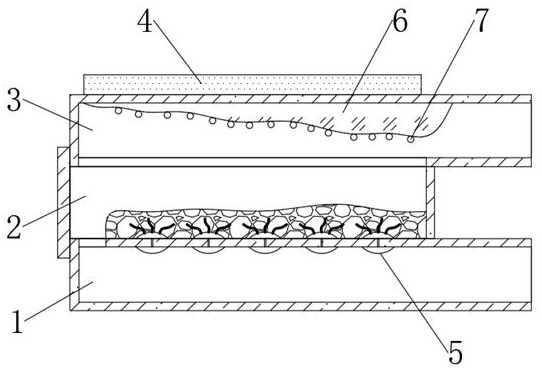

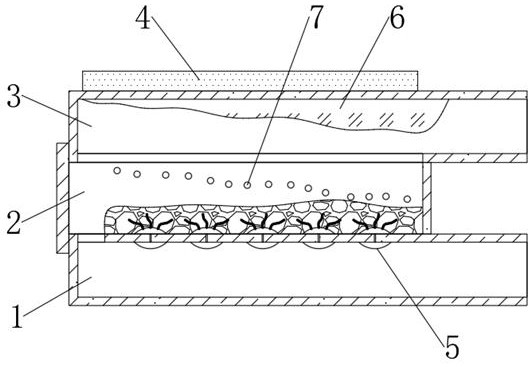

[0042] see Figure 1-3 , a kind of air-driven environment-friendly coal particle drying equipment, comprising an air inlet box 1, the upper end of the air inlet box 1 is fixedly connected with a material receiving frame 2, the upper end of the material receiving frame 2 is fixedly connected with an air outlet box 3, and the upper end of the air inlet box 1 is fixedly connected The left side is provided with an air inlet hole connected with the material frame 2, the lower end of the air outlet box 3 is provided with an air outlet hole matching the material frame 2, and the upper end of the air inlet box 1 is inlaid and connected with a plurality of evenly distributed oil-filled The upper end of the chuck 5 and the oil-filled chuck 5 are fixedly connected with a plurality of evenly distributed extension oil pipes 8, and the extension oil pipes 8 are connected with the oil-filled chuck 5, and the oil-filled chuck 5 is filled with heat-conducting oil, and the oil-filled chuck Coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com