Method for enhancing grouting effect of working face bottom plate detected through audio frequency electric perspective method

A technology of grouting effect and working face, which is applied in the field of underground geophysical exploration in coal mines, can solve the problems of great interference in detection results, increase production costs, and increase the number of drilling holes, so as to enhance anti-interference ability, improve accuracy, and improve reliability. The effect of noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in combination with specific embodiments.

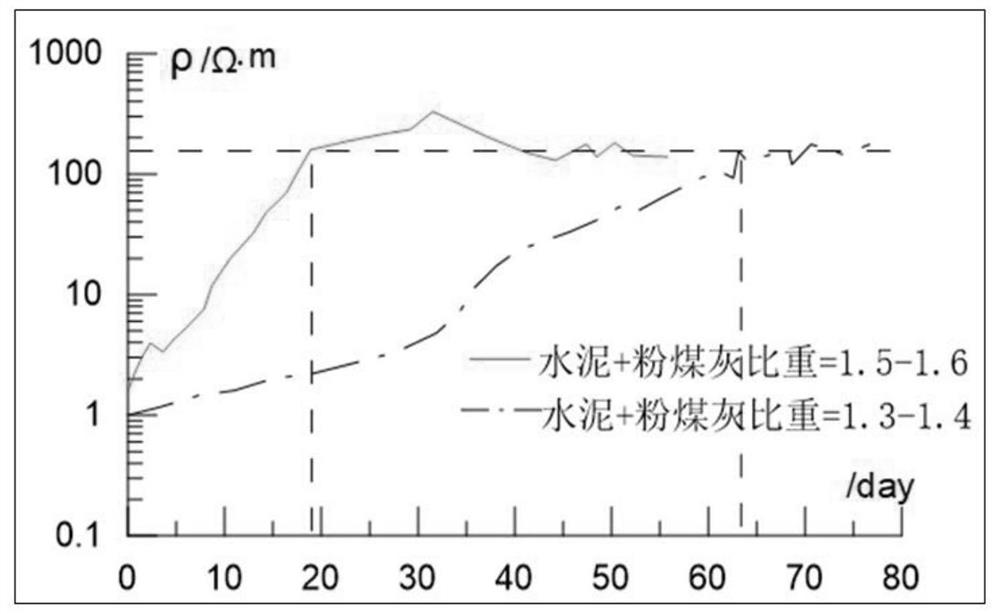

[0052] (1) Detect the original resistivity before grouting in the bottom plate of the working face to be tested

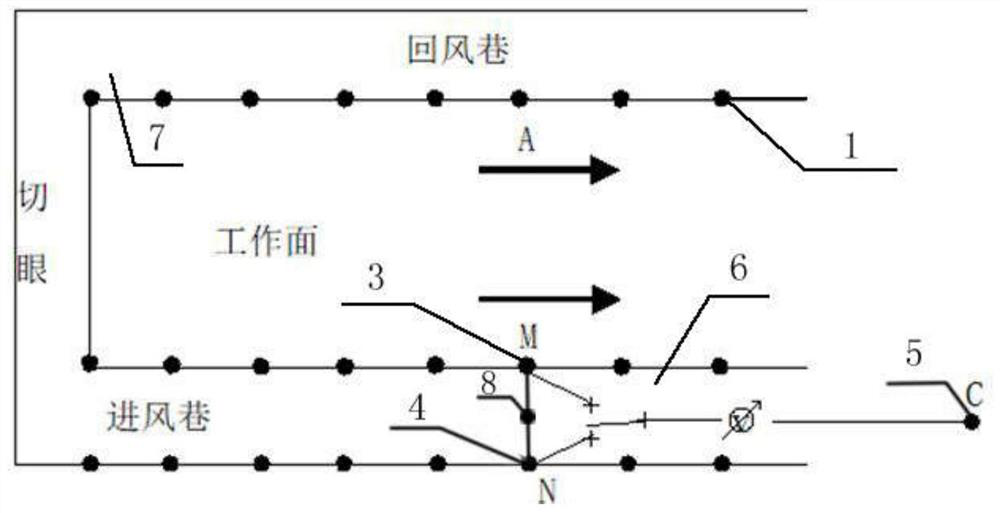

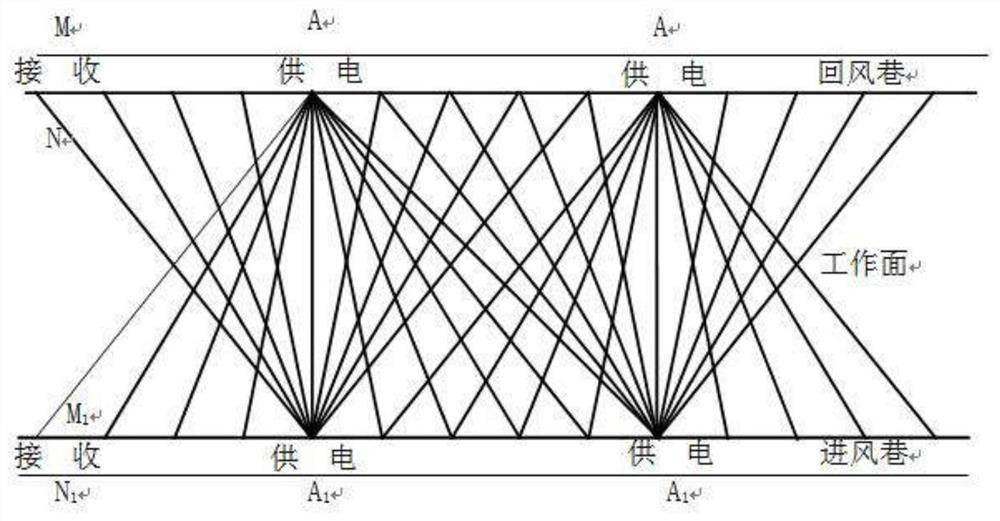

[0053] The detection device used is an enhanced audio monopole-dipole-dipole device, figure 1 Schematic diagram of the planar structure of the enhanced audio monopole-dipole-dipole device; the enhanced audio monopole-dipole-dipole device includes power supply electrode A 1, power supply electrode B 2, measurement electrode M 3, measurement electrode N 4, enhanced receiving Electrode C 5;

[0054] The power supply electrode A1 is set in the A-shun groove 7 of the working surface; the power supply electrode B 2 is infinity; the measuring electrode M 3 and the measuring electrode N 4 are set in the B-shun groove 6 of the working surface, and the distance between the measuring electrode M 3 and the measuring electrode N 4 Equal to the transverse width of the B-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com