Silicone rubber sealing element and preparation method thereof

A seal and silica gel technology, which is applied in the field of silica gel seals and its preparation, can solve problems such as poor sealing effect, easy to absorb dust, and affect computer operation, etc., to reduce the possibility, improve antistatic performance, and improve antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a silicone sealant, comprising the following preparation steps:

[0033] S1. Cut 500g of 70-degree silica gel into sheets with a thickness less than 50mm, then cut 500g of 70-degree silica gel, 500g of 50-degree silica gel, 15g of talcum powder, 2g of silicon carbide powder, 4g of terminal hydrogen-containing silicone oil and 0.55g Platinum (0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane was kneaded and rolled at 170°C for 10 minutes, then 18 g of vulcanizing agent was added, and then turned over for 5 minutes to make the vulcanizing agent Mix evenly, then add 8g of color masterbatch, turn over the material for 5 minutes, and roll it to obtain the rubber material;

[0034] S2. Put the rubber material into the corresponding seal mold and press for 55 seconds to form a silicone seal. When pressing, set the temperature of the upper mold to 200°C, the temperature of the lower mold to 195°C, and the low pressure to 200kgf / cm 3 , High pressure is 210...

Embodiment 2-9

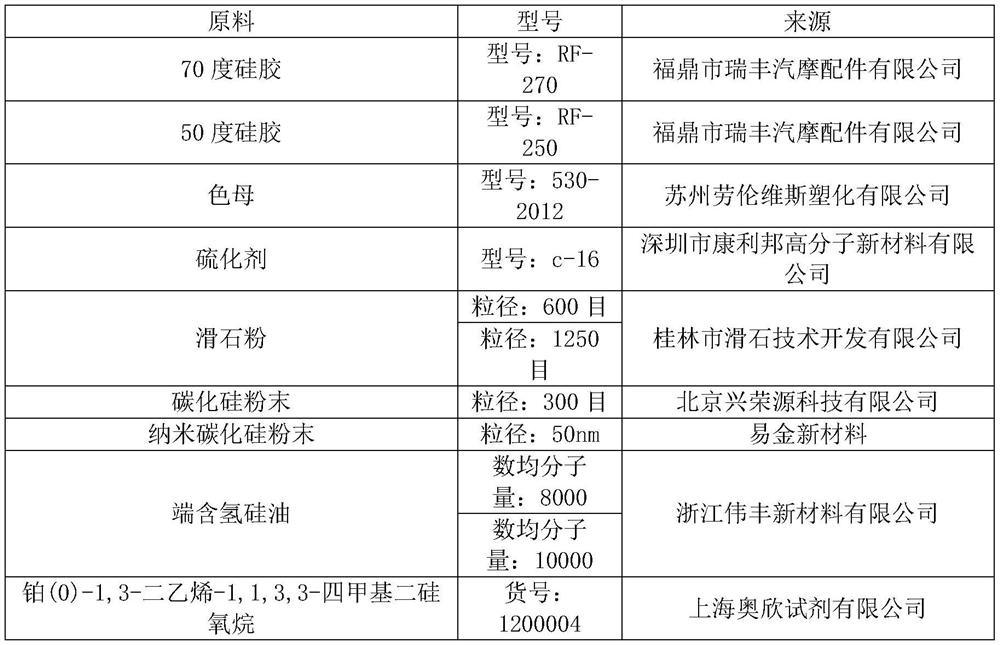

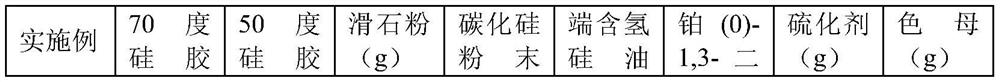

[0037] Embodiments 2-9 are all based on Embodiment 1, and differ from Embodiment 1 only in that the amounts of each raw material are different, see Table 2 for details.

[0038] Table 2. Each raw material consumption of embodiment 1-9

[0039]

[0040]

Embodiment 10

[0042] Example 10 is based on Example 1, and differs from Example 1 only in that the number average molecular weight of the terminal hydrogen-containing silicone oil used is 8000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com