Infant milk protein partial hydrolysis formula food for special medical use

A technology of formula food and milk protein, which is applied in the field of infant formula food and food, and can solve the problems of cost and flavor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 hydrolyzed whey protein

[0038] According to the previous research experience and the data of hydrolysis degree, time, bitterness value, flavor evaluation and other data in the actual hydrolysis experiment (not shown here for reasons of space), we selected alkaline protease, compound Three single-enzyme enzymatic hydrolysis methods of flavor protease and papain, and further determined their suitable enzymatic hydrolysis conditions:

[0039] Alkaline protease: 7% enzyme / substrate mass ratio, pH 8.5, temperature 50 degrees Celsius, time 4 hours;

[0040] Compound flavor protease: 9% enzyme / substrate mass ratio, pH 7, temperature 50 degrees Celsius, time 4 hours;

[0041] Papain: 6% enzyme / substrate mass ratio, pH 7, temperature 55 degrees Celsius, time 4 hours.

[0042] The following samples were prepared using the method described above:

[0043] Unhydrolyzed whey protein: whey protein samples that have not undergone any hydrolysis, he...

Embodiment 2

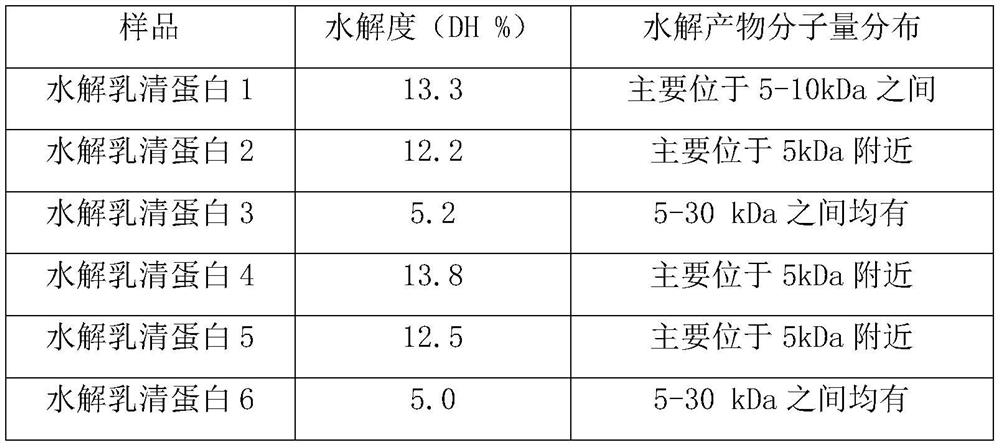

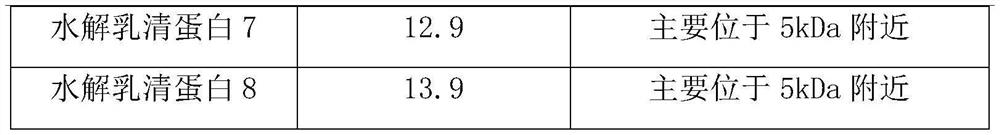

[0052] Embodiment 2 Basic property research of hydrolyzed whey protein

[0053] Determination of degree of hydrolysis:

[0054] Through the above-mentioned OPA method measurement and SDS electrophoresis observation, the hydrolysis of hydrolyzed whey protein 1-8 is shown in the following table:

[0055]Table 1 Hydrolysis of various hydrolyzed whey proteins:

[0056]

[0057]

[0058] The results showed that the enzymatic hydrolysis effect of alkaline protease and compound flavor protease was better than that of papain, and the fragment size after hydrolysis was significantly different from that of deep hydrolysis (it was generally believed that the 3kDa fragment was higher than 90%). After scoring and evaluating, the formula food prepared with the above-mentioned hydrolyzed whey protein 4 (the specific formula is described in the following examples) has a higher flavor and mouthfeel score than the applicant's self-made deeply hydrolyzed formula food (long-term enzymatic ...

Embodiment 3

[0059] Example 3 Sensitivity determination and short analysis of residual peptides

[0060] The β-HEX release rate of unhydrolyzed whey protein, hydrolyzed whey protein 1-8, and a commercially available deep hydrolyzed milk powder were tested using the above method, and the results are as follows:

[0061] Table 2 β-HEX release rate of various hydrolyzed whey proteins

[0062] sample β-HEX release rate (%) unhydrolyzed whey protein 44.51 Hydrolyzed Whey Protein 1 29.22 Hydrolyzed Whey Protein 2 28.75 Hydrolyzed Whey Protein 3 37.41 Hydrolyzed Whey Protein 4 20.34 Hydrolyzed Whey Protein 5 27.69 Hydrolyzed Whey Protein 6 36.71 Hydrolyzed Whey Protein 7 22.45 Hydrolyzed Whey Protein 8 23.96 Commercially available deep hydrolyzed milk powder 19.85

[0063] In combination with the results of Example 2, adding an appropriate amount of sodium pyrophosphate to complex metal components in whey protein or to emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com