Automatic low-temperature cold trap water removal system

A low-temperature cold trap, automatic technology, applied in the direction of condensation traps/cold partitions, refrigerators, refrigeration and liquefaction, etc., can solve the problems of affecting the continuity of detection, increase labor costs, gas circuit disconnection, etc., to reduce labor time cost, ensuring data stability, and the effect of simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

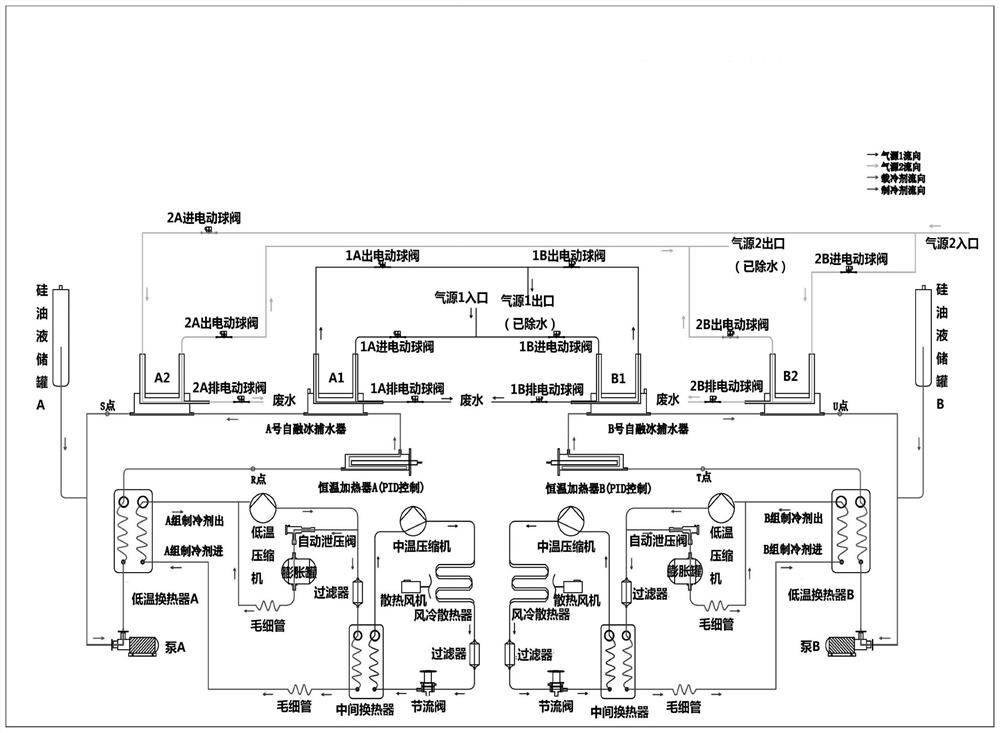

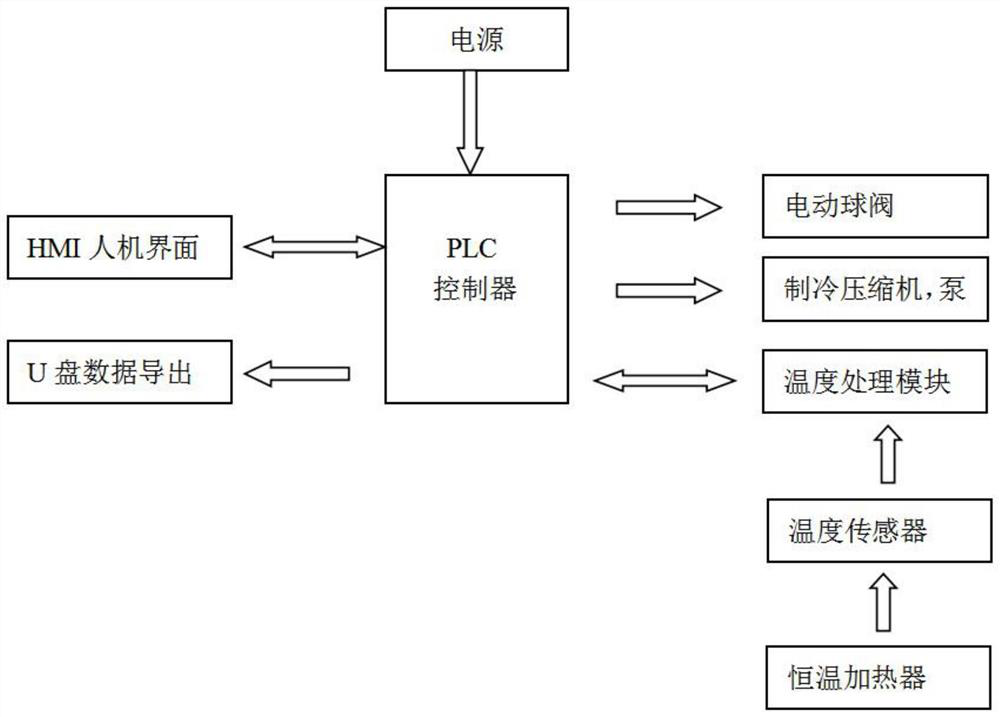

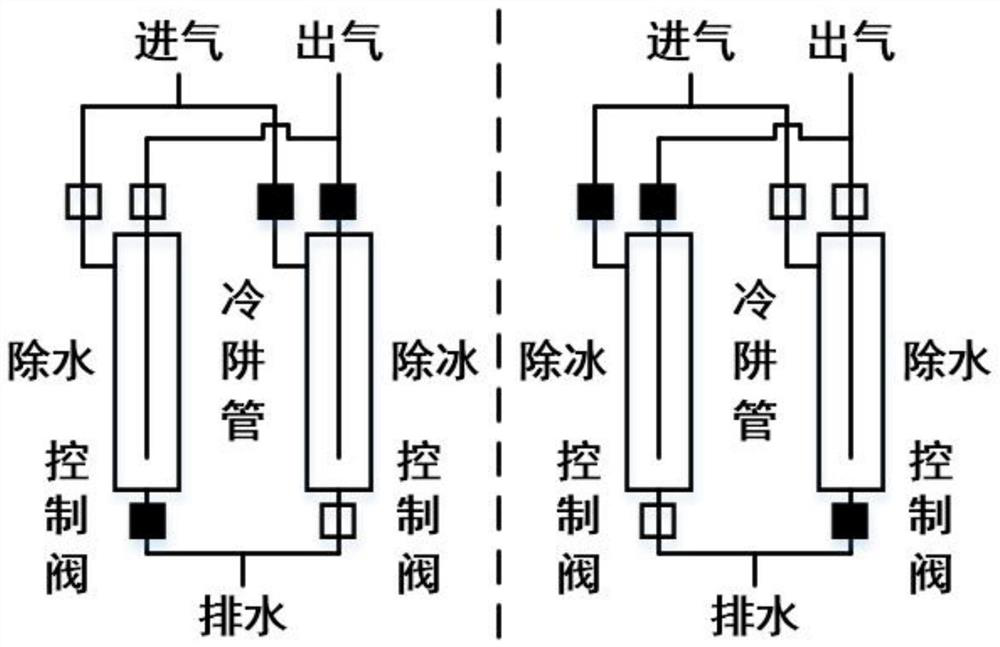

[0021] Embodiment 1 of the present application provides an automatic cryogenic cold trap water removal system, such as figure 1 As shown, it includes two independent water removal systems (i.e. No. A water removal system and No. B water removal system); each group of water removal systems includes a medium-temperature refrigeration cycle system, a low-temperature refrigeration cycle system, and a precision temperature control system for cryogenic liquids. Circulation system; the medium temperature refrigeration circulation system and the low temperature refrigeration circulation system are respectively connected to the two heat exchange tubes of the intermediate heat exchanger, and the low temperature refrigeration circulation system and the cryogenic liquid precision temperature control circulation system are respectively connected to the low temperature heat exchange tubes On the two heat exchange tubes; the medium-temperature refrigeration circulation system provides a mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com