Method for preparing bimetal composite plate through electroslag casting

A technology for electroslag casting and clad plate, which is applied in the field of electroslag casting to prepare bimetallic clad plates, can solve problems such as low efficiency, poor bonding strength, inability to scale production, etc., and achieve the effect of overcoming low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

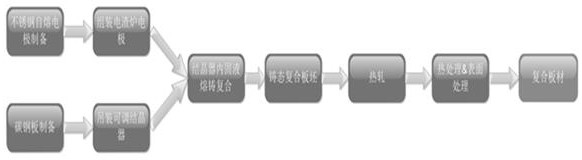

[0050] The slag furnace melting and casting composite bimetal clad plate process includes the following steps:

[0051] Step 1: Buy or make self-made 304 stainless steel self-fluxing electrodes for cladding materials required for electroslag melting stainless steel composite panels, size: 255×20×2700, 2 pieces;

[0052] The second step: purchase the base material Q235 carbon steel plate of the size required for electroslag melting stainless steel clad plate, size: 330×230×680;

[0053] The third step: remove the oil stain and scale of the Q235 carbon steel slab, especially the surface of the metallurgical joint surface of the carbon steel plate is required to be bright and free of rust and inclusions;

[0054] Step 4: Assemble 304 stainless steel self-fluxing electrodes and dummy electrodes, and clamp two stainless steel billet mother electrodes to the two chucks of the same cross arm of the bipolar parallel electroslag furnace at the same time;

[0055]Step 5: Before loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com