Circumferential weld narrow gap MAG welding process simulation and molten pool information acquisition device and method

A welding process and simulation device technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem that the flow behavior of the molten pool cannot be accurately seen in the transition of the droplet, and the molten pool and sidewall in the groove cannot be truly reflected. Welding conditions, obstacles to the study of the dynamic behavior of the molten pool in the narrow gap welding process, etc., to avoid unfused defects, optimize the groove size, and optimize the experimental design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

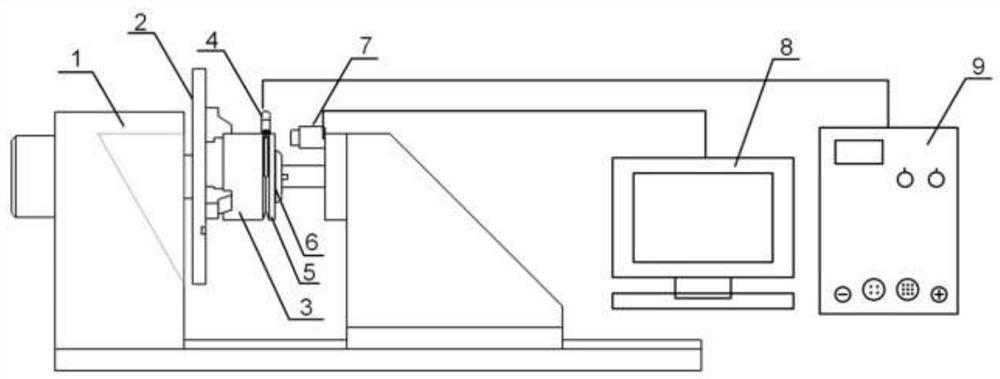

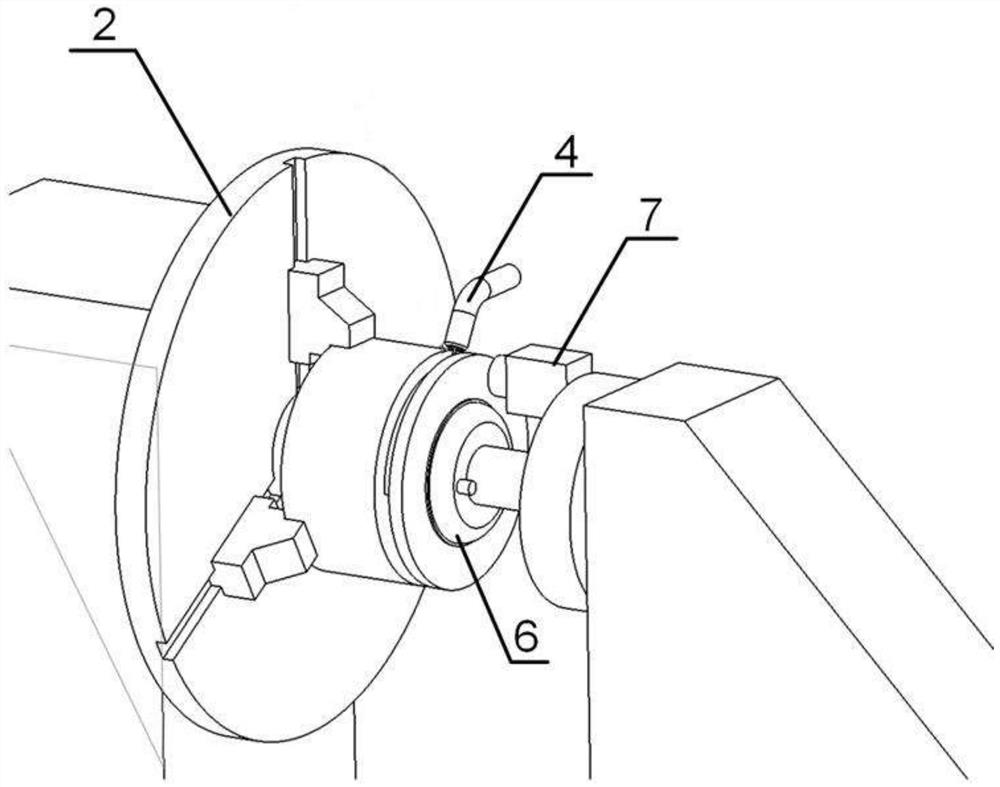

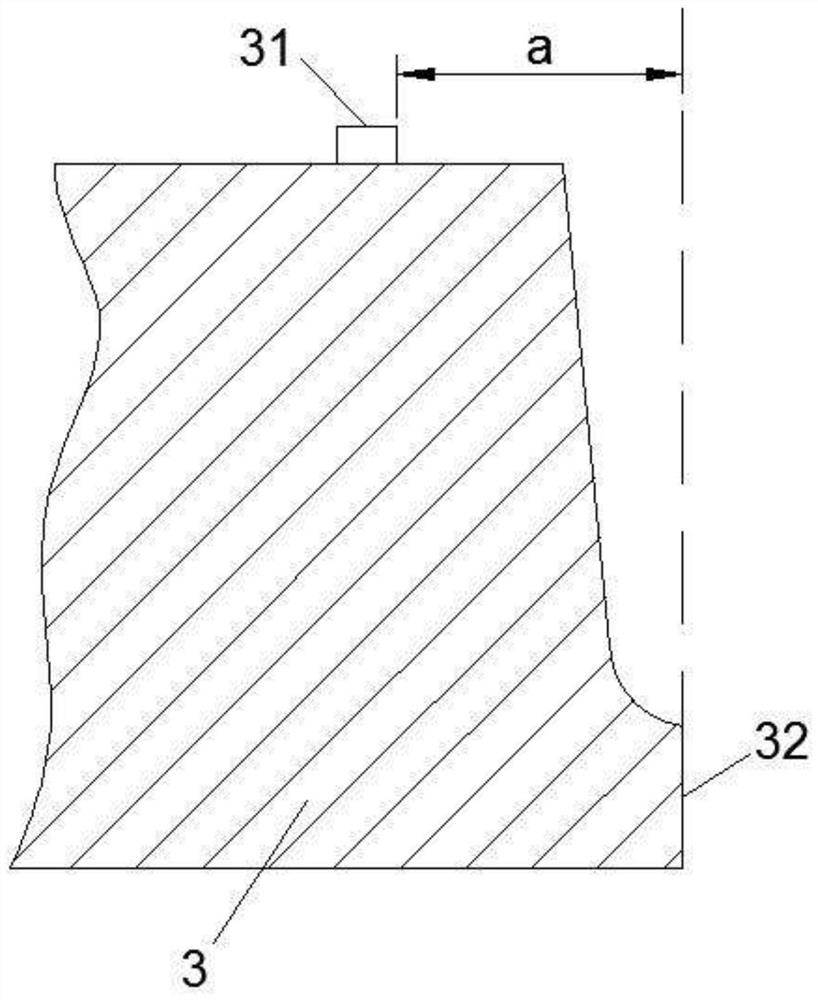

[0028] Such as figure 1 , figure 2 As shown, a girth weld narrow-gap MAG welding process simulation device includes: a workbench 1, on which a first fixture 2 and a second fixture 6 that can rotate coaxially; fixed on the first fixture 2 The metal test piece 3, one surface of the metal test piece 3 is provided with a designated welding groove; There is a specified welding groove, and forms a weld with the welding groove on the metal test piece 3; MAG welding machine 9 is used to perform simulated welding operations on the weld.

[0029] In this embodiment, the first fixture 2 is a three-jaw fixture; the second fixture 6 is a vacuum suction cup; the driving mechanism on the workbench 1 drives the three-jaw fixture to rotate, and the metal test piece 3 is clamped on the three-jaw fixture and The three-jaw clamp rotates coaxially and drives the transparent plate 5 to rotate. The light-transmitting plate 5 is GG17 high-temperature glass, through which the entire dynamic proces...

Embodiment 2

[0032] Such as figure 1 , figure 2 As shown, based on the simulation device for the narrow gap MAG welding process of the girth weld described in the first embodiment, this embodiment provides a melting pool characteristic information collection device for the narrow gap MAG welding process of the girth weld, including: The girth weld narrow-gap MAG welding process simulation device described above; the industrial camera 7 is installed on the workbench 1, and is used to collect the image information of the molten pool in the process of welding the weld seam by the MAG welding machine through the light-transmitting plate 5; the data The processing system 8 is configured to receive and process the image information of the molten pool collected by the industrial camera 7 to obtain characteristic information of the molten pool.

[0033] In this embodiment, the contact between the metal test piece 3 and the GG17 high-temperature glass is processed into a narrow-gap groove that si...

Embodiment 3

[0040] Based on the simulation device for the narrow-gap MAG welding process of the girth weld described in Embodiment 1 and the melting pool characteristic information collection device for the narrow-gap MAG welding process of the girth weld described in Embodiment 2, this embodiment provides a ring The use method of the molten pool feature information collection device in the narrow gap MAG welding process of the weld seam includes: installing the metal specimen with the welded groove on the first fixture; installing the light-transmitting plate with the welded groove on the second on the fixture, and fit the light-transmitting plate and the metal test piece together, so that the welding groove on the metal test piece and the welding groove on the light-transmitting plate form a weld; install the welding torch of the adjusted MAG welding machine At the position of the weld; start the debugged industrial camera and data processing system; start the MAG welding machine to weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com